Reebok 2012 Annual Report Download - page 141

Download and view the complete annual report

Please find page 141 of the 2012 Reebok annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

adidas Group

/

2012 Annual Report

Group Management Report – Our Group

119

2012

Sustainability

/

02.8

/

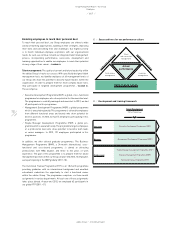

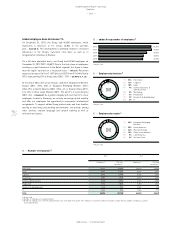

Improving our environmental footprint at own sites

An important part of our Group’s Environmental Strategy is the Green

Company initiative, which targets reducing the environmental footprint

of our own sites. The initiative provides a supporting framework,

guidance and communication platform for all Group entities to improve

their environmental footprint.

As part of this initiative, we have set Group-wide and site-specific 2015

targets related to carbon emissions, savings in energy, water and paper

consumption as well as sourcing green energy. One of the key goals

within the Green Company initiative is to operate certified environmental

management systems at major sites of the adidas Group. Overall, by

2015, we aim to reduce the relative carbon emissions at our own sites

by 30%. By the end of 2012, ten sites of the adidas Group had certified

environmental management systems in place. Read more about the

Green Company programme and our performance achievements on our

website :

//

WWW.ADIDAS-GROUP.COM/SUSTAINABILITY.

Sustainable materials

One key goal of our Environmental Strategy is to reduce the overall

environmental impact of materials used in our products. We aim to find

materials that reduce waste or have less of an impact throughout their

whole life cycle. The adidas Group has various initiatives in place that

help to achieve its goal to increase the usage of recycled and sustainable

materials.

One example is our participation in the Better Cotton Initiative, which was

co-founded by the adidas Group. We are committed to using 100% Better

Cotton in all our products by 2018. Better Cotton can be described as

sustainable cotton going mainstream, i.e. decreasing negative social and

environmental impacts of growing cotton by cutting water consumption

considerably and addressing pesticide management, crop rotation and

sound working conditions. In 2013, we will continue to launch products

containing Better Cotton. More information about Better Cotton can be

found on our website at :

//

WWW.ADIDAS-GROUP.COM/SUSTAINABILITY.

Another initiative is the adidas brand’s sustainable product programme

“Better Place”, which works with different product creation teams, as well

as cross-functional teams such as Sourcing, Corporate Communication

and Global Operations to create a sustainable product offering within

the adidas Sport Performance and Sport Style ranges. Some ways in

which “Better Place” works with product creation teams to increase

sustainable products is through the utilisation of sustainable materials,

environmental design and innovative manufacturing techniques within

the product creation process. These actions, or combinations of these

actions, have allowed “Better Place” to work with product creation

teams to create a larger sustainable product offering. The first adidas

“Better Place” products were introduced globally in 2009 in response

to increasing consumer demand for sustainable sports apparel and

footwear. These products have been a part of the adidas brand product

offering ever since.

The number of adidas products that either reached or exceeded the

baseline “Better Place” criteria has grown in recent years. This growth

is supported by ongoing innovation in the area of sustainable product

construction and manufacturing techniques, such as the low-waste

hot-runner injection technologies. Hot runners are a technology brought

over from the automotive industry, where injectable materials travel

through a heated channel directly from the machine to the mould, only

using the needed material. The result is no material overflow from the

mould.

In 2012, we focused on increasing the use of sustainable materials

such as recycled polyester, organic and Better Cotton and bio-based

materials. These environmentally preferred materials have replaced

conventional materials in many of our footwear and apparel products. In

addition to increasing the use of environmentally preferred materials, we

strive to continuously increase the range of more sustainable products by

developing sustainable product solutions and using innovative materials.

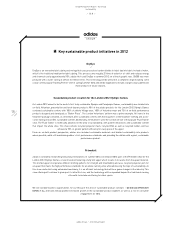

For example, in 2012, all our footwear products reached the minimum

sustainability levels required by the “Better Place” guidelines

/

KEY

SUSTAINABLE PRODUCT INITIATIVES IN 2012.

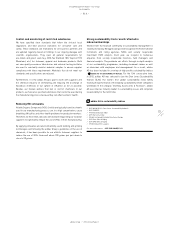

Driving environmental improvements in our supply chain

In our supply chain, activities focus on helping suppliers establish

sound environmental management systems at their manufacturing

plants to best reduce their negative environmental impacts. We have

guidelines and training programmes in place for our suppliers, using the

environmental performance of our own production sites as best practice

examples.

The majority of our footwear sourcing volume is produced in factories

which are OHSAS 18000 and/or ISO 14001 certified. The remaining

part of our footwear sourcing volume is produced in factories that

have management systems in place but have not yet been certified. All

footwear factories are regularly assessed against the adidas Group’s

standards on environment and workplace health and safety. In 2012, we

introduced “Environmental Key Performance Indicators” that allow us to

track the progress of environmental efforts undertaken by our strategic

suppliers. Furthermore, we have established a database to collect

environmental data from the factories of our core suppliers. A range of

other activities have been implemented to reduce our carbon footprint

in the supply and distribution chain. Examples of these are in the areas

of transportation and energy use. In the transportation of our products,

our policy is to minimise the impacts, in particular from airfreight

shipments, through improved order and production planning tools.