Reebok 2010 Annual Report Download - page 126

Download and view the complete annual report

Please find page 126 of the 2010 Reebok annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

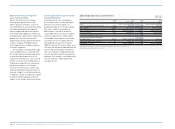

122 Group Management Report – Our Group Sustainability

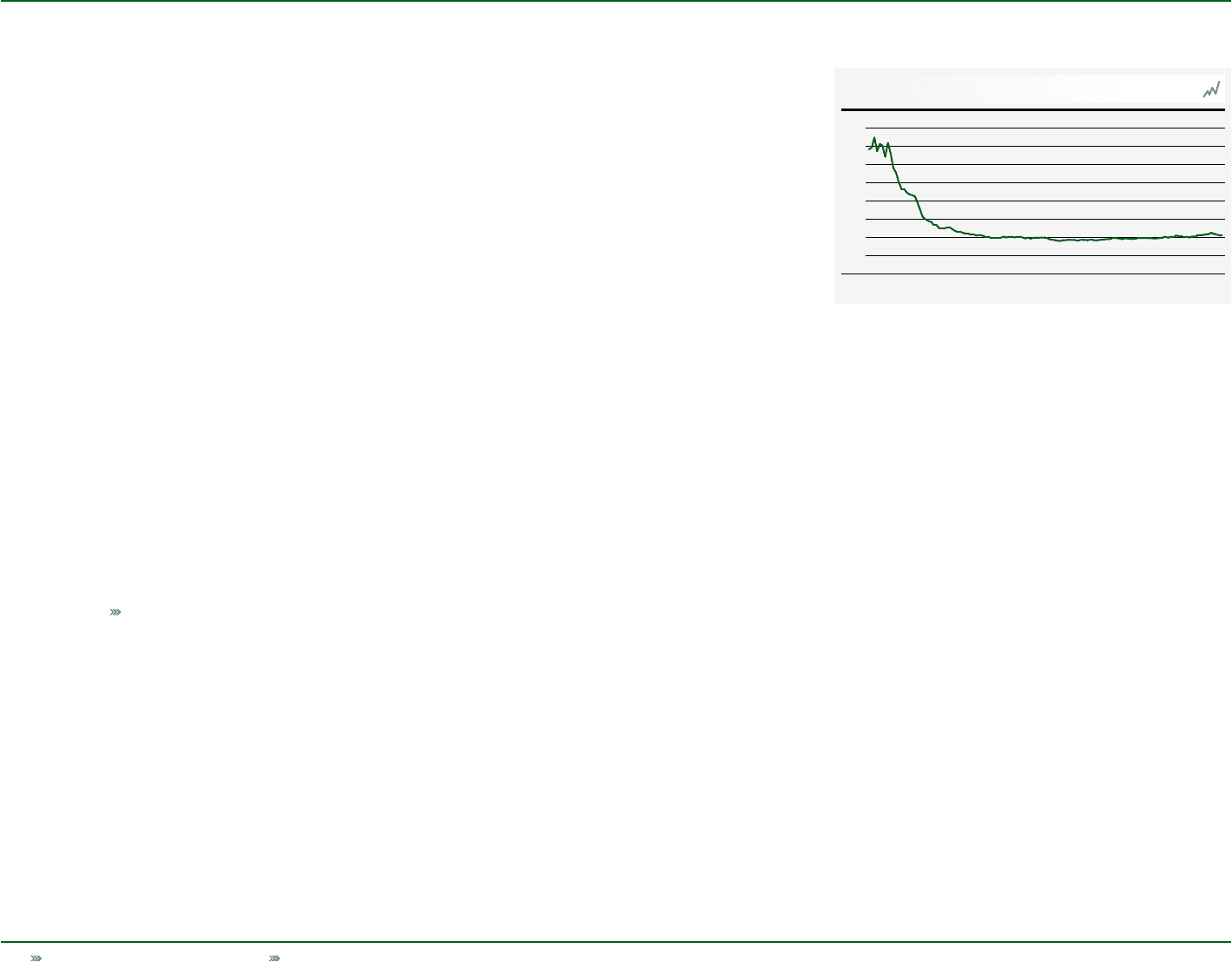

Volatile organic compounds consumption1)

in grams per pair of shoes produced

2000 2001 2002 2003 2004 2005 2006 2007 2008 2009 2010

120

80

40

0

1) At year-end.

02

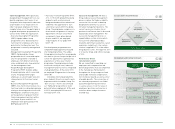

Strategic approach to managing

environmental impacts and tackling

climate change

Tackling climate change poses a number

of challenges for our company and

our manufacturing partners. Having

analysed the environmental footprint of

our business operations and building

on existing environmental initiatives, we

developed an Environmental Strategy in

2010 with defined targets until 2015. With

this strategy, we strive to continuously

reduce the company’s environmental

footprint by applying environmental best

practice in our daily work and in the

supply chain. We systematically look at

all relevant parts of the business and

value chain to become more thoughtful

and efficient in using resources as well

as help reduce operational costs. Our

initiatives span from product design

and creation to sourcing and manufac-

turing, also covering our own sites, own-

retail stores and all other sales points.

The focus is on energy, water conserva-

tion and discharge, waste and chemicals.

More details on our Environmental

Strategy can be found in our 2010 Social

and Environmental Online Report and

on our website at www.adidas-Group.com/

sustainability.

Improving our environmental

footprint at own sites

As an important part of our Group’s

Environmental Strategy, we launched the

Green Company Initiative, which targets

reducing the environmental footprint

of our own sites. The initiative provides

a supporting framework, guidance and

communication platform for all Group

entities to improve their environmental

footprint.

As part of this initiative, we have

set Group-wide and site-specific 2015

targets related to savings in energy

use, carbon emissions, water usage

and paper as well as sourcing green

energy. In these areas, our goals include

cutting the relative energy use by 20%,

the relative carbon emissions by 30%,

and reducing paper use by 50% per

employee. Further targets have been

specified for waste, purchasing practices

and mobility management. In addition

to the overall company goals, several

sites have set their own specific targets.

One of the key goals within the Green

Company Initiative has been to obtain

ISO 14001 certification for environmental

management systems established at six

major administration sites of the adidas

Group. This was achieved for five major

sites in 2010, all located in North America

(Portland, Carlsbad, Canton, Montreal

and Spartanburg). The certification of the

adidas Group Headquarters site “World of

Sports” in Herzogenaurach is scheduled

for 2011.

Driving environmental improvements

in our supply chain

In the supply chain, activities focus

on helping suppliers establish sound

environmental management systems at

their manufacturing plants to best reduce

their negative environmental impacts. We

have developed guidelines and training

programmes for our suppliers, using

the environmental performance of our

own production sites as examples of best

practice.

In 2010, our Group’s supply base

included 24 athletic footwear supplier

factories which were OHSAS 18000 and/

or ISO 14001 certified. These factories

produced around 83% of our footwear

sourcing volume. The remaining part

of our footwear sourcing volume

is produced in factories that have

management systems in place but have

not been certified. All footwear factories

are regularly assessed against the adidas

Group’s standards regarding environment

and workplace health and safety. A range

of other activities have been implemented

to reduce our carbon footprint in the

supply and distribution chain. Examples

of these are in the areas of transportation

and energy use. In the transportation of

our products, our policy is to minimise

the impacts, in particular from air freight

shipments, through improved order and

production planning tools.