Reebok 2010 Annual Report Download - page 112

Download and view the complete annual report

Please find page 112 of the 2010 Reebok annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

108 Group Management Report – Our Group Global Operations

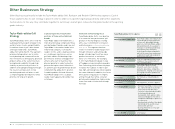

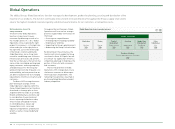

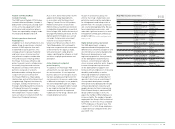

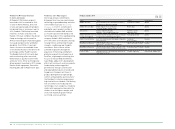

Suppliers by region 1 )

1) Figures include adidas, Reebok and adidas Golf, but exclude local sourcing

partners, sourcing agents, subcontractors, second-tier suppliers and licensee

factories.

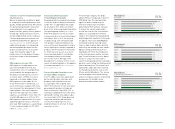

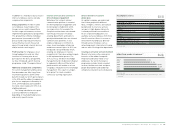

Footwear production by region 1 )

1) Figures include adidas, Reebok and adidas Golf.

03

04

75% Asia

16% Americas

9% Europe

97% Asia

2% Europe

1% Americas

Footwear production 1 )

in million pairs

1) Figures include adidas, Reebok and adidas Golf.

05

2007

2008

2009

2010

201

221

171

219

Several major programmes reach

important milestones in 2010

Throughout 2010, Global Operations

made significant progress on key

projects. In May, we saw the formal

opening of the Group’s Spartanburg

distribution facility in South Carolina,

USA. With this state-of-the-art facility,

we are now servicing our wholesale

customers as well as our own-retail and

e-commerce activities in the USA across

the brands adidas, Reebok, TaylorMade-

adidas Golf and Rockport – with 80% of

our customers receiving their orders in

three days or less. We also successfully

completed several important system

simplification projects. The Reebok and

Ashworth brands were integrated into the

long-term roll-out of the adidas Group’s

Global Procurement Solution (GPS).

adidas, Reebok and Ashworth purchase

orders are now procured through one

common platform covering the entire

flow from market demand, factory

planning through to supplier invoice

procurement and subsidiary billing. In

total, the GPS 2.0 release replaced five

major IT applications. We also reduced

the total number of supply planning

systems across the adidas Group from

three to one, establishing a common

planning, reporting and communication

platform. Another major achievement

in 2010 was the official implementation

of the Fast and Lean Creation process

for footwear. Product creation teams

are now developing around 75% of all

footwear directly with factories, laying the

foundation for the introduction of creation

calendars of 12 months or less.

Fast and Lean Creation for apparel

also reached a major milestone with

the launch of a new product lifecycle

management system, FlexPLM, within

just eight months of the project launch.

Also in 2010, Global Operations teams

contributed to both the Group’s Virtu-

alisation programme by creating over

18,000 articles as 3D files, and to the

“Fit & Size” programme which involved

the adjustment of over 500 base patterns

to current consumers’ body shapes for

an improved overall fit of garments.

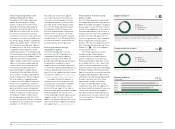

Majority of production through

independent suppliers

To minimise production costs, we

outsource over 95% of production to

independent third-party suppliers,

primarily located in Asia. While we

provide them with detailed specifications

for production and delivery, these

suppliers possess excellent expertise in

cost-efficient, high-volume production of

footwear, apparel and accessories. The

latest list of our supplier factories can be

found on our website www.adidas-Group.

com/en/sustainability/suppliers_and_workers.

The adidas Group also operates a

limited amount of own production and

assembly sites in Germany (1), Sweden

(1), Finland (1), the USA (4), Canada

(4), China (1) and Japan (1). In order to

ensure the high quality consumers expect

from our products, we enforce strict

control and inspection procedures at our

suppliers and in our own factories. In

addition, we promote adherence to social

and environmental standards throughout

our supply chain see Sustainability, p. 120.

Overall number of manufacturing

partners stable

In 2010, Global Operations worked with

270 independent manufacturing partners.

While the number of suppliers in apparel

decreased as a result of further rational-

isation of the supply base, it increased in

footwear and hardware. The increase in

footwear was the result of the significant

growth in volumes and expansion into

new sourcing countries (e.g. Cambodia).

Of our independent manufacturing

partners, 75% were located in Asia, 16%

were located in the Americas and 9% in

Europe see 03. 32% of all suppliers

were located in China.

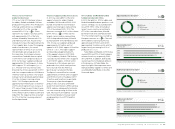

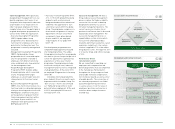

Our Global Operations function

manages product development,

commercialisation and distribution,

and also supervises sourcing for our

Wholesale and Retail segments as well

as for adidas Golf see 01. Due to the

specific sourcing requirements in their

respective fields of business, TaylorMade,

Rockport, Reebok-CCM Hockey and the

Sports Licensed Division are not serviced

through Global Operations, but instead

utilise their own purchasing organisation.

In order to quickly seize short-term

opportunities in their local market

or react to trade regulations, Group

subsidiaries may, with the approval of

our Social and Environmental team, also

source from selected local suppliers

outside the realm of Global Operations.

Local purchases, however, account only

for a minor portion of the Group’s total

sourcing volume.