Reebok 2010 Annual Report Download - page 111

Download and view the complete annual report

Please find page 111 of the 2010 Reebok annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

Group Management Report – Our Group Global Operations 107

Ensuring cost competitiveness: As

part of this priority, Global Operations

will focus on further optimising

product creation through a more

efficient material and colour selection

process. This, coupled with increased

automation in manufacturing, will

enhance productivity, shorten lead

times and improve overall quality. These

improvements are expected to enhance

profitability for the Group and ensure

we provide our consumers with the best

value proposition in the industry.

The Profitability Management

department within Global Operations

assumes a central role in realising cost

competitiveness by driving our strategic

costing efforts and optimising our buying

strategies. This includes monitoring

macroeconomic trends, to identify the

future impact on product costs as well as

the ongoing financial assessment of the

adidas Group’s supply base.

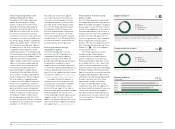

Providing industry-leading availability:

Building on the solid platform that has

been established to ensure product avail-

ability, Global Operations will further

shorten our order-to-delivery lead times.

This will be accomplished by estab-

lishing and offering a set of tailored and

sophisticated replenishment models to

our customers via improvements in our

planning systems and processes. The

development of risk-oriented planning

and production models for selected

product ranges as well as the shift from

buying to inventory planning at our distri-

bution centres both form key require-

ments for the successful delivery of this

initiative.

Enabling later ordering: Enabling later

ordering is a cross-functional priority in

Global Operations focused on allowing

our customers to order our products

closer to the time of sale, facilitating

buying decisions that are based on better

market knowledge.

This will support our Route 2015

goal of reducing the lead times across

the Group’s product portfolio to 60 days

or less. Specifically, the initiative will

focus on immediately reducing produc-

tion lead times on the majority of Reebok

footwear from 90 days to 60 days. Since

the majority of adidas footwear is already

on 60 days, the change will allow us to

align sales processes across the brands

and improve efficiencies. Preparations

are also underway to bring apparel lead

times down to 60 days or less over time.

The above improvements involve

establishing a greater regional source

base for apparel, which will enable us to

manufacture closer to our key markets to

deliver and replenish products faster.

Supporting the Group’s growth projects:

Global Operations will support the growth

projects outlined in the Group’s Route

2015 plan, such as the adidas NEO label,

key market programmes, Retail and

eCommerce as well as other key brand

programmes such as customisation

see Global Brands Strategy, p. 87 and Global Sales

Strategy, p. 82.

For example, with the adidas NEO

label, Global Operations will support

this business with fast fashion creation,

sourcing and supply chain management

capabilities. For Retail, Global Operations

will continue to build the processes and

systems backbone with the ultimate goal

being a demand-driven supply chain

that leverages existing short lead time

production models to improve availability

without excessive inventory see Retail

Strategy, p. 84.

Finally, Global Operations will focus

on evolving existing customisation

models in support of business expansion,

particularly within our eCommerce

channel.

Modernising the Group’s infrastructure:

Global Operations will continue to focus

on building the required infrastructure,

processes and systems to support the

Group’s growth plans. This will include

further process simplification, consol-

idation of legacy systems and distribu-

tion structures, as well as the creation

of state-of-the-art systems required

to support new business demands. An

example of this is the opening of our

new Spartanburg distribution campus

designed to support growth in the USA.

Also under this priority, the function

will continue delivering its existing

long-term improvement programmes

such as Fast and Lean Creation for

apparel, the roll-out of the Global

Procurement Solution platform and the

expansion of virtualisation to new product

categories and the design teams.

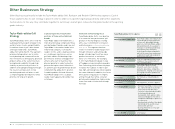

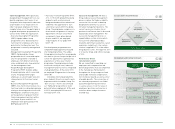

Global Operations strategic pillars

Replenishment Provide high product availability

and timely and fast deliveries to

Wholesale and Retail customers

while minimising finished goods

inventory, to support the Group’s

controlled space initiatives.

End-to-End Profitability Identify key cost and profitability

drivers and their interrelationships to

optimise decision-making to mitigate

financial risks and ensure the long-

term profitability of the Group and its

supply base.

Adaptive Supply Network Enhance the flexibility and

responsiveness of both the Global

Operations Sourcing and Supply

Chain Management organisations to

satisfy fast-changing market needs.

End-to-End Planning Optimise the Group’s demand and

supply planning system landscape

to improve efficiency, transparency

and cross-functionality of processes

across the Wholesale and Retail

segments as well as Other

Businesses.

Accelerated Creation to Shelf Build capabilities, processes and

technologies that drive faster,

smarter and more efficient product

creation to enhance the Group’s top-

line and bottom-line growth.

02