Reebok 2009 Annual Report Download - page 107

Download and view the complete annual report

Please find page 107 of the 2009 Reebok annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

Training to achieve sustainable

compliance

To achieve long-term sustainable compli-

ance in the supply chain, we consider

training even more important than

monitoring and policing factories. Our

SEA team offers specific training courses

and workshops for factory supervisors

and managers to help them apply our

Standards and implement best practices.

These workshops include, for example,

introductory training on our Workplace

Standards and SEA operating guidelines,

detailed training on effective health,

safety and environmental practices as

well as training in the correct application

of rating and compliance planning tools

and supplier self-assessment methods.

Further, we promote the establishment

of sustainable structures that actively

involve workers and management of our

suppliers as well as local employee asso-

ciations and non-governmental organisa-

tions (NGOs). The team also organises

workshops for licensees, agents and

adidas Group business entities in order

to build personnel capacities through-

out our company. In this way, acceptable

working conditions become a routine part

of business activities. In 2009, the SEA

team conducted 216 training sessions

and workshops (2008: 251).

Encouraging self-governance

Good management systems help factories

improve their day-to-day operations

and support the process of internalisa-

tion and self-governance. Therefore,

we support our core business partners

in establishing management systems

with internationally recognised stand-

ards such as ISO 14001 for environmen-

tal management. By running a certified

management system, our suppliers dem-

onstrate commitment to continuously

enhancing their performance. We help

them build or improve human resources

systems to maintain proper working

conditions, including factory grievance

systems to routinely find and fix non-

compliance issues. Further, by enforcing

employment standards at the sites of our

manufacturing suppliers, we empower

workers to protect their own rights and

take an active role in decision-making. In

2009, our Group’s supply base included

19 athletic footwear suppliers’ factories,

which were OHSAS 18000 and/or ISO

14001 certified. These factories produced

around 82% of our footwear sourcing

volume. The remaining 18% of our foot-

wear sourcing volume is produced in

factories that have management systems

in place but have not been certified. All

footwear factories are regularly assessed

against the adidas Group’s standards

regarding environment and workplace

health and safety.

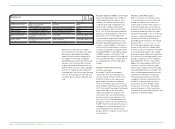

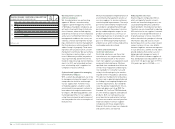

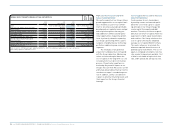

Monitoring through factory inspections

The SEA team assesses compliance with

our Workplace Standards by means of

factory inspections. Our auditors check

performance against a customised risk

list for each factory that is monitored.

The methodology is linked to a factory

rating which measures the effectiveness

of compliance systems and the work of

their administrators. This enables us to

precisely determine training needs at

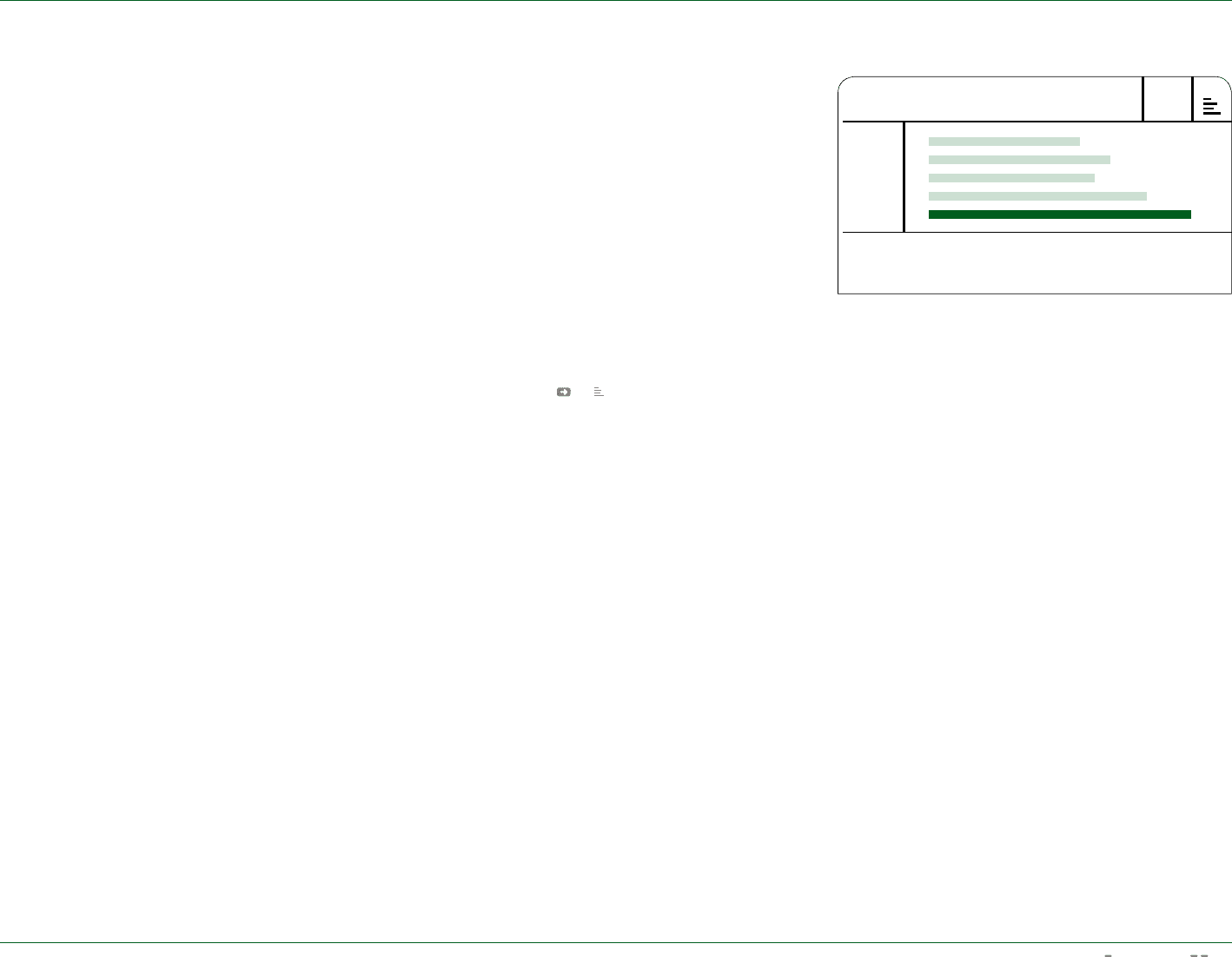

our suppliers’ factories. During 2009,

we conducted 1,592 factory visits (2008:

1,323 visits) involving management and

worker interviews, document review,

facility inspections and training sessions

at different levels in our supply chain

see 01. In addition to our own

monitoring activities, we value

independent assessment by third

parties to demonstrate the credibility of

and provide verified information about

our programme to stakeholders. As a

member of the Fair Labor Association

(FLA), the adidas Group is subject to

external assessment by independent

monitors, participation in the FLA

third-party complaint system and public

reporting. In 2008, the monitoring

programme of the adidas Group was

re-accredited by the FLA for a period

of two years. This decision was based

on independent factory monitoring and

verification reports of supplier facilities,

and a thorough audit of monitoring

protocols, training programmes and

auditing systems. Since joining the FLA,

more than 240 Independent External

Monitoring (IEM) audits and verification

visits have been conducted at adidas

Group suppliers.

N

°-

01

NUMBER OF FACTORY VISITS

2005 1 )

2006 2 )

2007

2008

2009

916

1,101

1,007

1,323

1,592

1) Including Salomon.

2) Including Reebok, Rockport and Reebok-CCM Hockey from February 1, 2006

onwards.

GROUP MANAGEMENT REPORT – OUR GROUP Sustainability 103