Chrysler 2014 Annual Report Download - page 132

Download and view the complete annual report

Please find page 132 of the 2014 Chrysler annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.-

1

1 -

2

2 -

3

3 -

4

4 -

5

5 -

6

6 -

7

7 -

8

8 -

9

9 -

10

10 -

11

11 -

12

12 -

13

13 -

14

14 -

15

15 -

16

16 -

17

17 -

18

18 -

19

19 -

20

20 -

21

21 -

22

22 -

23

23 -

24

24 -

25

25 -

26

26 -

27

27 -

28

28 -

29

29 -

30

30 -

31

31 -

32

32 -

33

33 -

34

34 -

35

35 -

36

36 -

37

37 -

38

38 -

39

39 -

40

40 -

41

41 -

42

42 -

43

43 -

44

44 -

45

45 -

46

46 -

47

47 -

48

48 -

49

49 -

50

50 -

51

51 -

52

52 -

53

53 -

54

54 -

55

55 -

56

56 -

57

57 -

58

58 -

59

59 -

60

60 -

61

61 -

62

62 -

63

63 -

64

64 -

65

65 -

66

66 -

67

67 -

68

68 -

69

69 -

70

70 -

71

71 -

72

72 -

73

73 -

74

74 -

75

75 -

76

76 -

77

77 -

78

78 -

79

79 -

80

80 -

81

81 -

82

82 -

83

83 -

84

84 -

85

85 -

86

86 -

87

87 -

88

88 -

89

89 -

90

90 -

91

91 -

92

92 -

93

93 -

94

94 -

95

95 -

96

96 -

97

97 -

98

98 -

99

99 -

100

100 -

101

101 -

102

102 -

103

103 -

104

104 -

105

105 -

106

106 -

107

107 -

108

108 -

109

109 -

110

110 -

111

111 -

112

112 -

113

113 -

114

114 -

115

115 -

116

116 -

117

117 -

118

118 -

119

119 -

120

120 -

121

121 -

122

122 -

123

123 -

124

124 -

125

125 -

126

126 -

127

127 -

128

128 -

129

129 -

130

130 -

131

131 -

132

132 -

133

133 -

134

134 -

135

135 -

136

136 -

137

137 -

138

138 -

139

139 -

140

140 -

141

141 -

142

142 -

143

143 -

144

144 -

145

145 -

146

146 -

147

147 -

148

148 -

149

149 -

150

150 -

151

151 -

152

152 -

153

153 -

154

154 -

155

155 -

156

156 -

157

157 -

158

158 -

159

159 -

160

160 -

161

161 -

162

162 -

163

163 -

164

164 -

165

165 -

166

166 -

167

167 -

168

168 -

169

169 -

170

170 -

171

171 -

172

172 -

173

173 -

174

174 -

175

175 -

176

176 -

177

177 -

178

178 -

179

179 -

180

180 -

181

181 -

182

182 -

183

183 -

184

184 -

185

185 -

186

186 -

187

187 -

188

188 -

189

189 -

190

190 -

191

191 -

192

192 -

193

193 -

194

194 -

195

195 -

196

196 -

197

197 -

198

198 -

199

199 -

200

200 -

201

201 -

202

202 -

203

203 -

204

204 -

205

205 -

206

206 -

207

207 -

208

208 -

209

209 -

210

210 -

211

211 -

212

212 -

213

213 -

214

214 -

215

215 -

216

216 -

217

217 -

218

218 -

219

219 -

220

220 -

221

221 -

222

222 -

223

223 -

224

224 -

225

225 -

226

226 -

227

227 -

228

228 -

229

229 -

230

230 -

231

231 -

232

232 -

233

233 -

234

234 -

235

235 -

236

236 -

237

237 -

238

238 -

239

239 -

240

240 -

241

241 -

242

242 -

243

243 -

244

244 -

245

245 -

246

246 -

247

247 -

248

248 -

249

249 -

250

250 -

251

251 -

252

252 -

253

253 -

254

254 -

255

255 -

256

256 -

257

257 -

258

258 -

259

259 -

260

260 -

261

261 -

262

262 -

263

263 -

264

264 -

265

265 -

266

266 -

267

267 -

268

268 -

269

269 -

270

270 -

271

271 -

272

272 -

273

273 -

274

274 -

275

275 -

276

276 -

277

277 -

278

278 -

279

279 -

280

280 -

281

281 -

282

282 -

283

283 -

284

284 -

285

285 -

286

286 -

287

287 -

288

288 -

289

289 -

290

290 -

291

291 -

292

292 -

293

293 -

294

294 -

295

295 -

296

296 -

297

297 -

298

298 -

299

299 -

300

300 -

301

301 -

302

302 -

303

303

|

|

130 2014 | ANNUAL REPORT

Sustainability Disclosure

World class manufacturing processes

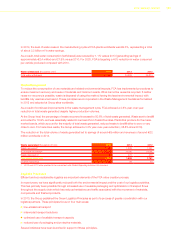

The World Class Manufacturing (WCM) program was first adopted about 10 years ago and has been implemented at

nearly all FCA plants worldwide. WCM represents the concrete application of our model of environmental sustainability

and, in particular, our efforts to reduce the impacts of our production processes. WCM is a rigorous manufacturing

methodology that involves the entire organization and encompasses all phases of production and distribution. In 2014,

approximately 48,000 WCM-related projects were implemented, including several specifically targeted at reducing

environmental impacts. Through the Environment Pillar, in particular, specific tools and methodologies are developed

to reduce waste and optimize the use of natural resources. Approximately 3,700 projects based on this pillar led to

reductions in natural resources consumption.

The Group has also developed an Environmental Management System (EMS), aligned with ISO 14001 standards,

which has been implemented worldwide. The EMS consists of a system of methodologies and processes designed to

prevent or reduce the environmental impact of the Group’s manufacturing activities through, for example, reductions

in emissions, water consumption and waste generation and conservation of energy and raw materials. At year-end

2014, 100% of FCA plants included in the 2012 scope of reporting were ISO 14001 certified.

Energy Consumption and Emissions

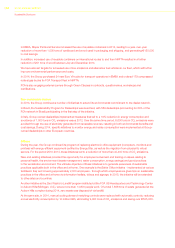

In response to increasingly stringent environmental regulations, the Group is continuously researching solutions

that will enable further reductions in greenhouse gas emissions and the use of fossil fuels. Over time, this has also

generated significant savings in energy-related costs.

In 2014, approximately 2,700 energy-related projects developed under WCM contributed to a reduction of approximately

3,300 terajoules in energy used, with a corresponding reduction of around 290,000 tons in CO2 emissions.

As a result of the success of these energy-related initiatives, energy consumption remained in line with the prior year

- despite a year-over-year increase in production volumes - and was well below the 2010 level in both absolute terms

and on a per vehicle produced basis.

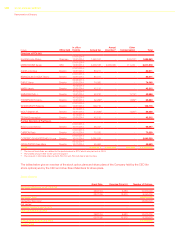

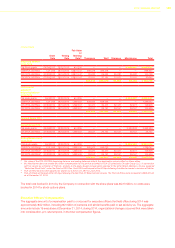

Direct and indirect energy consumption (terajoules) 2014 2013 2012

Total energy consumption 48,645 48,322 45,692

Total CO2 emissions from manufacturing processes also remained stable compared with 2013, but well below the

2010 level also on both a total and per vehicle produced basis.

FCA uses CO2 emissions per vehicle produced as the primary indicator of its energy performance and, for 2020, is

targeting a 32% reduction compared with 2010.

Total CO2 emissions (thousands of tons of CO2)2014 2013 2012

Total CO2 emissions 4,283 4,178 3,965

In 2014, 20.4% of electricity used at FCA plants was from renewable sources.

Water Management

In many parts of the world, water scarcity is one of the greatest challenges faced by governments, businesses and

individuals.

To protect this essential natural resource, the Group has adopted Water Management Guidelines that establish criteria

for sustainable management of the entire water cycle, including technologies and procedures to maximize recycling

and reuse of water and minimize the level of pollutants in discharged water.