Volvo 2015 Annual Report Download - page 48

Download and view the complete annual report

Please find page 48 of the 2015 Volvo annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

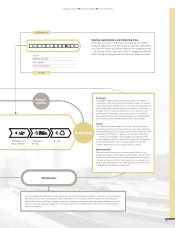

The Volvo Group works consistently with lean meth-

odologies to use less material as well as pro-

cesses to integrate more recycled materials,

reduce waste and energy, recover heat, and

assess our water footprint.

We offer refurbished spare parts as a way of

extending the useful life of our products, and to reduce costs for

our customers. Remanufacturing consists of three different parts:

1. Collecting: the customer’s worn part is collected and

replaced with an exchange part – this part can be new or

remanufactured.

2. Repairing: once the core is deemed reusable, it will be dis-

assembled, cleaned, re-machined, reassembled and tested.

3. Replacing: a new customer buys the remanufactured part

from the dealer.

Growing remanufacturing business

Remanufacturing engines, gear boxes and other spare parts is a

growing trend and a growing part of the Volvo Group’s business.

In 2015, total Volvo Group sales of remanufactured components

amounted to SEK 8.3 billion, an increase of close to 20% com-

pared with 2014.

The Volvo Group has more than 50 years of experience and

eight remanufacturing centers worldwide handling used compo-

nents from our whole range of products. The first center opened

in 1960 in Flen, Sweden. Other centers are located in France,

Japan, Brazil, US and China. In 2015 a new center in Bangalore,

India, was inaugurated. The center will play an important role in

the aftermarket offer for Volvo branded trucks, buses and con-

struction equipment in the Indian market.

Remanufacturing is also contributing from a societal perspec-

tive as it is more labor intensive than new production and demands

high-skilled employees.

Remanufactured components are offered to Volvo Group cus-

tomers worldwide. Through exchange, engines, gearboxes, exhaust

filters and rear axle transmissions can be renovated to the same

condition as new parts, and our range continues to increase. Cus-

tomers benefit from the same quality and a full warranty, delivered

at a lower price.

Environmentally, remanufacturing minimizes the need for raw

materials. It also significantly reduces energy consumption and

emissions. For example, a remanufactured engine saves up to

80% of the energy needed to build a new engine and dramatically

cuts the emissions of nitrogen oxides and carbon dioxide. It also

ensures that potentially dangerous residuals inside worn compo-

nents are dealt with correctly.

TAKING A CIRCULAR

APPROACH

Improved resource efficiency, reuse and recycling are increasingly important for society and our

industry tocounteract increasing demands and costs on the use of the planet’s finite natural capital.

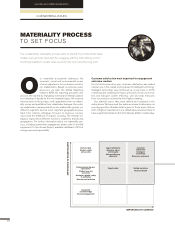

Circular product development

A truck produced by the Volvo Group is largely recyclable, since

almost 85% of its weight consists of metal – mostly iron, steel and

aluminum. The additional materials are mainly plastic, rubber and

material from electronics components.

In order to work efficiently, recycling and remanufacturing

activities have to be considered during the product planning

phase. The Volvo Group’s experts within this area, therefore works

closely together with product developers to enable disassembly

workers to extract the most material, and value, from our vehicles

at the end of their life.

Triple win

In the last couple of years Volvo Group North America have

marketed remanufactured components for the aftermarket. It is

called the “The Triple Win” because:

• Customers can buy a high quality part for a significantly lower price

• Volvo Group can increase sales

• The reduced number of new components and quality-assured

reused components deliver environmental benefits.

The project focuses on powertrain components and contains a

mix of remanufactured components from suppliers and from

Volvo operations internally.

In 2015, total Volvo Group sales

of remanufactured components

increased by close to 20% compared

with 2014.

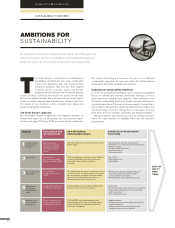

A GLOBAL GROUP BUSINESS MODEL

REUSE & RECYCLING

46