Volvo 2015 Annual Report Download - page 34

Download and view the complete annual report

Please find page 34 of the 2015 Volvo annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

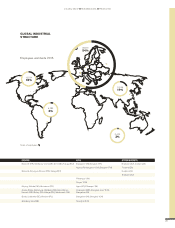

The Volvo Group has 66 production sites in 18

countries around the world. In addition to our pro-

duction sites, our industrial operations worldwide

include several product development centers, and

a large number of parts distribution centers and

logistics centers. With such a global spread we

have developed tools, processes and production systems to help

us set a global standard of excellence and guide our employees

on responsible behavior. Read about our health, safety and well-

being work for our employees on page 74.

Component factories and assembly plants

Our industrial system for trucks consists of capital-intensive com-

ponent factories as well as labor-intensive assembly plants. The

component factories supply the Group’s needs on a global basis

whereas assembly plants in most cases are located close to

end-markets to cater for different local needs and specifications.

Engine and transmission manufacturing are common for all

Volvo Group business lines. Köping, Sweden is a global hub for

heavy-duty transmissions.

When it comes to engines the Group has two major hubs –

Skövde, Sweden for heavy-duty diesel engines and Pithampur,

India for medium-duty engines. Medium-duty engines are also

supplied by the German engine manufacturer Deutz, primarily for

Volvo Construction Equipment.

For Volvo Construction Equipment, production is more central-

ized to a few larger hubs with the big wheel loaders and articu-

lated haulers being produced mainly in Sweden and excavators

mainly in South Korea.

Major restructuring completed

During 2014 and 2015 changes in our European industrial struc-

ture for truck assembly were implemented in order to enhance the

efficiency of our manufacturing and thus strengthen competitive-

ness. In Sweden, the cab trim operations were relocated from

Umeå to Gothenburg and the assembly of heavy-duty trucks was

concentrated to one line. In France, the assembly of medium-duty

trucks was concentrated to Blainville. During this period, produc-

tion in Japan underwent major changes with a phasing-out of non-

core operations and a consolidation of operations to Ageo, adapting

the capacity to the domestic demand of Japan and close markets.

With these changes completed the future direction of the truck

manufacturing is more focused on continuous improvements to drive

increased productivity rather than on large restructuring activities.

EFFICIENT AND RELIABLE

PRODUCTION

The Volvo Group has a global industrial and logistics system that is well-invested

and able to efficiently meet the demand from our customers.

Stronger structure through joint ventures

The Volvo Group industrial position has been strengthened in

many markets in Asia through the historical acquisitions of UD

Trucks and Lingong (SDLG) and the cooperation within trucks

and buses with India-based Eicher Motors. The acquisition of

45% of the Chinese manufacturer Dongfeng Commercial Vehi-

cles (DFCV), which was completed in January 2015, will contri-

bute further to this development. Through its acquisitions the

Volvo Group has also established a global industrial structure

with manu facturing as well as sales and distribution channels on

all continents.

Continuous improvements

In order to produce the best products on the market we are focus-

ing on reduced costs, improved quality and shorter lead times. We

are driving continuous improvement through the Volvo Production

System (VPS). VPS is used for many processes throughout the

organization, including production, product development, logistics

and administration. VPS uses methods that streamline operations

and minimize productivity losses. The system includes tools for

measuring and improving workplace safety, health and wellbeing.

At our production units, we have quality coordinators, safety

delegates and environmental coordinators and we measure and

monitor to continuously improve.

MANAGEMENT SYSTEMS

All the Volvo Group’s wholly-owned production facili-

ties and distribution centers are third-party audited.

We hold certificates as follows:

• ISO 9001 Quality management system: 100% of

production facilities and 90% of distribution centers

• ISO 14001 Environmental management system: 98%

ofproduction facilities and 90% of distribution centers

• ISO 50001 Energy standard: Macungie, Hagerstown

and New River Valley plants in the US.

A GLOBAL GROUP BUSINESS MODEL

PRODUCTION

32