Volvo 2015 Annual Report Download - page 32

Download and view the complete annual report

Please find page 32 of the 2015 Volvo annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

To deliver sustainable transport solutions, we have

high expectations of all our business partners. In

2015, we bought goods and services at a total

value of SEK 210.6 billion from our suppliers.

Close to 43,000 suppliers delivered parts and ser-

vices to the Volvo Group. Of those almost 6,500

supplied automotive parts. Our suppliers play a significant role in

driving future growth, innovation, profitability and continuous

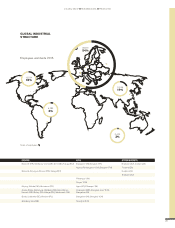

improvement for the Volvo Group. Generally we source from sup-

pliers close to our production sites to ensure efficient flow of sup-

plies. This means that most suppliers are located in Europe and

North America. At the same time, the Group’s expansion in Asia

has led to an increased number of new suppliers located there.

Responsible sourcing

We have to act responsibly to be seen as a trustworthy business

partner. Doing so will result in high productivity and stable long-

term relationships, which benefit all parties. Our Code of Conduct

sets out the principles and minimum standards of responsible

behavior. Since 1996, our responsible sourcing program has con-

sistently increased supplier requirements on environmental issues,

business ethics, human rights and social issues.

The Volvo Group requires our suppliers of automotive compo-

nents to have a third-party certified environmental and quality

management system. Around 95% of the Volvo Group spending

on automotive products comes from suppliers that are certified in

accordance with ISO 14001 or its equivalent.

The Volvo Group and its suppliers must comply with the EU

requirements on chemicals and harmful substances, in accord-

ance with the REACH (Registration, Evaluation, Authorization and

Restriction of Chemicals) legislation. Suppliers must also meet

additional requirements on chemicals from the Volvo Group.

The majority of our purchasers and quality engineers have now

had training on the business ethics, social justice and environ-

mental issues affecting our supply chain.

After supplier training in CSR related issues in for instance Tur-

key and Poland, our training was extended to India during 2015.

Developing ethical assessment

In line with general automotive industry practice, the Volvo Group

uses a self-assessment approach to evaluate potential and current

suppliers’ performance and compliance with our ethical require-

ments. The Supplier Evaluation Model requires core suppliers and

especially those in high-risk countries or segments to update

their assessments in our supplier system, before new contracts

are signed.

RESPONSIBLE SOURCING

TO REDUCE RISK

Our suppliers are expected to be cost efficient and deliver the highest quality standards on products and services

all the way from project planning, to production and delivery to our plants as well as providing a competitive

aftermarket offer for the complete product life cycle. Building long-term partnerships with our suppliers gives

thema strong foundation for success and a possibility to contribute to the Volvo Group’s bottom line.

Since 2009, new suppliers have to be approved by the Group’s

Global Sourcing Committe. Potential suppliers of automotive

products are also evaluated by a quality engineer.

In addition, we conduct regular site visits during product devel-

opment, which gives us better control over our existing supply chain.

In 2015 we ran a pilot project to ascertain that potential conflict

minerals in our products originated from approved smelters. The

process is designed to meet both the demands from the US

Dodd-Frank Act and the upcoming European regulation.

The result from the pilot project shows that the components

comes from approved smelters.

As a member of the European Automotive Working Group on

Supply Chain Sustainability, the Volvo Group has contributed to a

harmonization of assessments for automotive suppliers. This pro-

cess will facilitate an accurate and transparent way of working.

We began to use the new process in 2015 and will implement it

fully during 2016.

Assessing our suppliers

During 2015, 86% of the value bought from automotive product

suppliers was assessed from a CSR perspective compared to

80% in 2014. Of these suppliers, the equivalent of 79% (72)

passed the assessement. It is of business importance that we

rank countries from a CSR risk perspective. In 2015, 9% (12) of

the value bought from automotive product suppliers operated

from a high-risk country. Of this value the CSR assessed percent-

age was at the same level as last year i.e. 92%.

We also assess our non-automotive suppliers, such as suppli-

ers of indirect parts and services like IT and Logistic Services,

from a risk segment perspective. During 2015, around 15% (4) of

these suppliers, operating in high-risk segments, were assessed

and 70% (63) passed the assessment.

SUPPLIER ASSESSMENT

Our supplier assessment poses approximately

40questions relating to the principles in our Code

ofConduct, including:

• Social performance

• Work environment and conditions

• Human and labor rights

• Environmental care

• Business ethics

A GLOBAL GROUP BUSINESS MODEL

SUPPLY CHAIN

30