Volvo 2015 Annual Report Download - page 36

Download and view the complete annual report

Please find page 36 of the 2015 Volvo annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

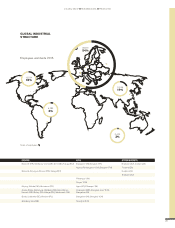

A GLOBAL GROUP BUSINESS MODEL PRODUCTION

Carbon emissions from production

In 2015, direct CO2 emissions from the Volvo Group’s production

facilities decreased from 231,000 tons to 221,000 tons. About

40% of our total energy consumption came from low-carbon

renewable sources, including hydropower electricity and biomass

heating.

The Volvo Group has carbon-neutral facilities in Ghent, Bel-

gium, as well as Vara, Tuve and Braås in Sweden. Additionally we

have facilities buying 100% of their electricity produced from

landfill gas instead of fossil fuels.

Chemicals and harmful substances

Our global environmental standard for production plants requires

processes for health and environmental assessment of all chem-

icals. Since 1996, to restrict the use of chemicals with unwanted

characteristics, the Volvo Group has maintained a ‘black list’ of

prohibited chemicals and a ‘grey list’ of products whose use must

be limited. The lists are revised annually and serve as tools for

substituting harmful substances in our production processes.

Waste and water

The Volvo Group’s minimum requirements on production plants

include sorting and quantifying all waste at source, implementing

measures to reduce the quantity of waste and increase reuse,

material recycling and energy recovery as well as reducing the

quantity of waste consigned to landfill. Waste is usually classified

as either hazardous or non-hazardous. The total amount of haz-

ardous waste in 2015 was 27,824 tons, compared with 24,944

tons in 2014, an increase of close to 12%. Hazardous waste sent

to landfill amounted to 1,155 tons.

Water consumption continues to decrease, from 4,982,000 m3

in 2014 to 4,919,000 m3 in 2015. During the year an evaluation

was done of areas with the highest water-related risks. As a result

we are working with preventive and mitigating activities at our

facilities in for instance India.

Transport and logistics

Carbon emissions resulting from our internal freight transport and

deliveries to customers are more than double the CO2 emissions

from our production plants. This is therefore a prioritized area for

us with many different initiatives.

Carbon emissions for the total volume transported in our man-

ufacturing supply chain were calculated at 505,000 tons for 2014.

This is equivalent to reduced CO2 emissions of close to 3%. Data

for 2015 will be available in May 2016.

During 2015, we optimized rail transport in Sweden from Umeå

to Tuve by utilizing free space and enhancing on and offloading.

This resulted in an annual CO2 saving of approximately 100,000 kg.

This is equivalent to the CO2 emissions of 230 trucks transporting

the same freight by road.

The majority of the Volvo Group’s major transport suppliers are

certified in accordance with ISO 14001, or equivalent.

MAJ

O

R PR

O

DU

C

TI

O

N FA

C

ILITIES

NO

RTH AMERI

C

A S

O

UTH AMERI

C

A

VolvoTruck

s

N

ew River Valley

(

US

)

C

uritiba

(

BR

)

UD

T

ruc

k

s

R

enau

l

t

T

ruc

k

s

M

a

ck

T

ru

cks

M

acun

g

ie (US)

E

i

che

r

*

Dongfeng Trucks

*

En

g

ines and transmission

s

H

a

g

erstown

(

US

)

C

uritiba

(

BR

)

C

onstruction E

q

ui

p

ment Shippensburg

(

US

)

Pederneiras

(

BR

)

Bu

ses

St Claire, St Eustache, St Francois du lac (CA)

M

exico City

(

MX

)

, Plattsbur

g

h

(

US

)

C

uritiba

(

BR

)

V

o

l

vo

P

enta

L

exington

(

US

)

*

Ownership ≥ 45%

34