Reebok 2015 Annual Report Download - page 99

Download and view the complete annual report

Please find page 99 of the 2015 Reebok annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.-

1

1 -

2

2 -

3

3 -

4

4 -

5

5 -

6

6 -

7

7 -

8

8 -

9

9 -

10

10 -

11

11 -

12

12 -

13

13 -

14

14 -

15

15 -

16

16 -

17

17 -

18

18 -

19

19 -

20

20 -

21

21 -

22

22 -

23

23 -

24

24 -

25

25 -

26

26 -

27

27 -

28

28 -

29

29 -

30

30 -

31

31 -

32

32 -

33

33 -

34

34 -

35

35 -

36

36 -

37

37 -

38

38 -

39

39 -

40

40 -

41

41 -

42

42 -

43

43 -

44

44 -

45

45 -

46

46 -

47

47 -

48

48 -

49

49 -

50

50 -

51

51 -

52

52 -

53

53 -

54

54 -

55

55 -

56

56 -

57

57 -

58

58 -

59

59 -

60

60 -

61

61 -

62

62 -

63

63 -

64

64 -

65

65 -

66

66 -

67

67 -

68

68 -

69

69 -

70

70 -

71

71 -

72

72 -

73

73 -

74

74 -

75

75 -

76

76 -

77

77 -

78

78 -

79

79 -

80

80 -

81

81 -

82

82 -

83

83 -

84

84 -

85

85 -

86

86 -

87

87 -

88

88 -

89

89 -

90

90 -

91

91 -

92

92 -

93

93 -

94

94 -

95

95 -

96

96 -

97

97 -

98

98 -

99

99 -

100

100 -

101

101 -

102

102 -

103

103 -

104

104 -

105

105 -

106

106 -

107

107 -

108

108 -

109

109 -

110

110 -

111

111 -

112

112 -

113

113 -

114

114 -

115

115 -

116

116 -

117

117 -

118

118 -

119

119 -

120

120 -

121

121 -

122

122 -

123

123 -

124

124 -

125

125 -

126

126 -

127

127 -

128

128 -

129

129 -

130

130 -

131

131 -

132

132 -

133

133 -

134

134 -

135

135 -

136

136 -

137

137 -

138

138 -

139

139 -

140

140 -

141

141 -

142

142 -

143

143 -

144

144 -

145

145 -

146

146 -

147

147 -

148

148 -

149

149 -

150

150 -

151

151 -

152

152 -

153

153 -

154

154 -

155

155 -

156

156 -

157

157 -

158

158 -

159

159 -

160

160 -

161

161 -

162

162 -

163

163 -

164

164 -

165

165 -

166

166 -

167

167 -

168

168 -

169

169 -

170

170 -

171

171 -

172

172 -

173

173 -

174

174 -

175

175 -

176

176 -

177

177 -

178

178 -

179

179 -

180

180 -

181

181 -

182

182 -

183

183 -

184

184 -

185

185 -

186

186 -

187

187 -

188

188 -

189

189 -

190

190 -

191

191 -

192

192 -

193

193 -

194

194 -

195

195 -

196

196 -

197

197 -

198

198 -

199

199 -

200

200 -

201

201 -

202

202 -

203

203 -

204

204 -

205

205 -

206

206 -

207

207 -

208

208 -

209

209 -

210

210 -

211

211 -

212

212 -

213

213 -

214

214 -

215

215 -

216

216 -

217

217 -

218

218 -

219

219 -

220

220 -

221

221 -

222

222 -

223

223 -

224

224 -

225

225 -

226

226 -

227

227 -

228

228 -

229

229 -

230

230 -

231

231 -

232

232 -

233

233 -

234

234 -

235

235 -

236

236 -

237

237 -

238

238 -

239

239 -

240

240 -

241

241 -

242

242 -

243

243 -

244

244 -

245

245 -

246

246 -

247

247 -

248

248 -

249

249 -

250

250 -

251

251 -

252

252 -

253

253 -

254

254 -

255

255 -

256

256 -

257

257 -

258

258 -

259

259 -

260

260 -

261

261 -

262

262 -

263

263 -

264

264 -

265

265 -

266

266 -

267

267 -

268

268 -

269

269 -

270

270

|

|

GROUP MANAGEMENT REPORT – OUR GROUP

Sustainability

95

2

•Factory visits: During 2015, we conducted 1,255 factory visits (2014: 1,320 visits) comprising different

types of audits (including chemical management audits), trainings and meetings with factory management

as well as employees at various levels in our supply chain. In addition to our own monitoring activities,

we value independent and unannounced assessment by third parties to demonstrate the credibility of

and provide verified information about our programme to stakeholders. As a member of the Fair Labor

Association (FLA), the adidas Group is subject to external assessment by independent monitors, partici-

pation in the FLA third-party complaint system and public reporting. Since joining the organisation in

1999, the monitoring programme of the adidas Group has been accredited twice by the FLA. During

this period, more than 300 independent assessments have been conducted at adidas Group suppliers.

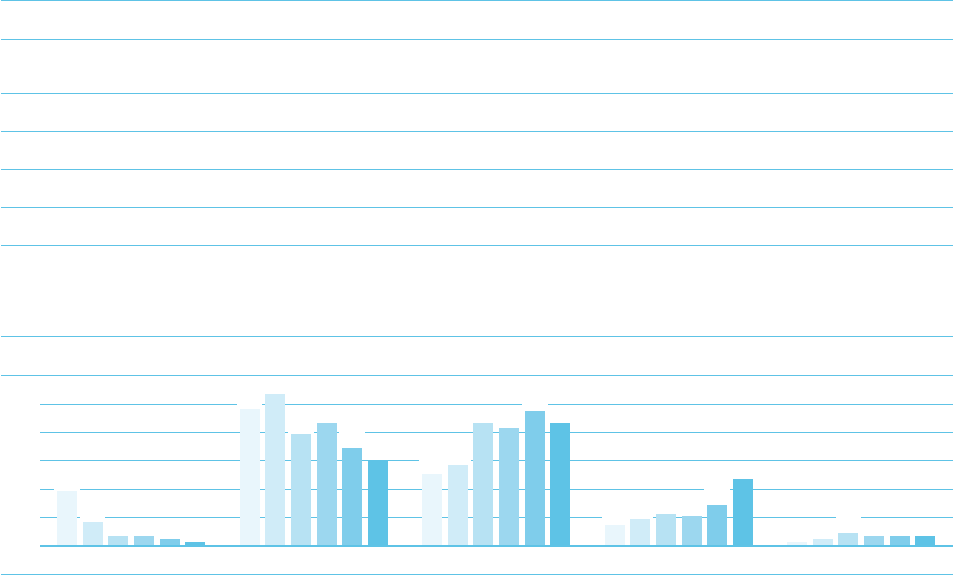

•Compliance rating: According to the results of factory inspections, suppliers are assessed with a score

between 1C and 5C, with 5C being the best rating. The rating results are shared with our Sourcing

teams which then decide whether and to which extent we continue the business relationship with a

specific supplier. In 2015, we saw a further decline in the number of low-performing suppliers (1C and

2C) and at the same time a notable increase of suppliers qualifying for self-governance (factories that

have reached 4C or 5C status). More supplier factories qualifying for self-governance status means

that factories have proven to operate effective human resources, health and safety as well as environ-

mental management systems by themselves. As a result, we were able to reduce the number of factory

visits in 2015 compared to the prior year. Overall, 68% (2014: 64%) of our direct suppliers have received

a 3C (good) or better rating.

01COMPLIANCE RATINGS

Grade KPI score band Performance description

1C 0% – 29% There are numerous severe non-compliance issues and no compliance management and compliance practices

in place. The factory has been given notice that business will be terminated unless there is immediate

improvement.

2C 30% – 59% There are some non-compliance issues and no compliance management systems. However, there are some

effective compliance practices being delivered.

3C 60% – 79% There are minor non-compliance issues. The factory has compliance management systems and some effective

compliance practices in place.

4C 80% – 89% Generally, there are no non-compliance issues. The factory has compliance management systems in place,

and most of the components are effective.

5C 90% – 100% There are no non-compliance issues and all of the factory's management systems and practices are well

delivered and effective.

02DEVELOPMENT BYCOMPLIANCE RATINGS 1IN %

1C 2C 3C 4C 5C

50

40

30

20

10

0

■

2010

■

2011

■

2012

■

2013

■

2014

■

2015

1 The table presents the C-KPI percentage of direct suppliers. Please note that in 2012 we moved to a KPI reporting methodology that only considers the latest KPI score of each supplier,

instead of taking the average of all previous KPI scores into account.

8

53

28

9

2

3

43 41

10

3

19

48

25

7

1

3

39 43

11

4

2

34

47

14

3

1

30

43

23

3