Volvo 2005 Annual Report Download - page 43

Download and view the complete annual report

Please find page 43 of the 2005 Volvo annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

Volvo Group 2005 39

More information

More information about Volvo’s envir-

onment efforts including pol icies,

environmental information about

products and production, emissions

requirements and educational

materials is available at:

www.volvo.com

fifth to one sixth of EU limits for new painting

facilities. Investments in technology for envir-

onmental improvements amount to approxi-

mately SEK 245 M.

Each year the existence of polluted land

on properties owned by the Volvo Group is

catalogued. In general, these occurrences

have a historical background. During 2005

cleaning-up activities took place in five prop-

erties.

The Volvo Group generates transports to

and from production facilities all over the

world. The Group’s logistics managers regu-

la rly re vie w the se flows and con ti nuous ly make

improvements to achieve considerably fewer

transports and a significant reduction in the

total impact on the environment. In order to

better assess the impact on the environment

from our logistics work, Volvo Logistics has

produced a system for calculating the environ-

mental load.

In September 2005, Volvo Truck’s New

River Valley factory in Virginia in the US was

awarded the Governor’s Environmental Excel-

lence Award for Manufacturers. This prize is

awarded to recognize companies that strive to

maintain the highest levels of quality in their

environmental work and who do more than

merely fulfill prescribed requirements.

In the beginning of 2005, Renault Trucks

int ro duc ed a ne w p roc ess fo r e lec t ro ly ti c c oat in g

of the cab. The new coating process has reduced

water consumption by some 20% and chemical

oxygen demand by some 35% per cab.

Requirements on suppliers

and dealers

Since 1996, the Volvo Group has imposed

demands on the environmental efforts of sup-

pliers and dealers. Environmental require-

ments form part of our evaluation of suppliers

and our subsequent purchases. Recently,

focus has also been directed toward the en-

vironmental efforts of dealers. For example,

Volvo Trucks North America is conducting a

joint project for the purpose of further improv-

ing environmental efforts of North American

dealers.

Greater energy efficiency

The Volvo Group has ambitious environmental

challenges for energy consumption in produc-

tion facilities. All of the companies and operat-

ions in the Group have been challenged to

reduce energy consumption by 50% per manu-

factured unit during a five-year period.

Reducing carbon-dioxide emissions is another

target. The challenge is to double the utiliza-

tion of carbon-dioxide neutral energy over a

five-year period.

Energy savings are not only positive for the

environment, they also involve cost savings.

For example, Volvo Trucks invested SEK 80 M

in energy-saving measures between 2001

and 2004, leading to a 29% reduction in

energy utilization. These investments resulted

in savings of SEK 200 M during the period and

are expected to save at least SEK 50 M annu-

ally.

An ambitious energy savings program at the

truck factory in New River Valley in the US

was introduced in 2003. The program resulted

in a 20% reduction in the use of electricity

and natural gas during 2004. Savings to date

amount to approximately SEK 20 M.

In the US, Volvo Trucks is working with Mack

Trucks in a voluntary project to reduce carbon-

dioxide consumption. The project is called

Climate Leaders and is being managed by the

US Environmental Protection Agency (EPA).

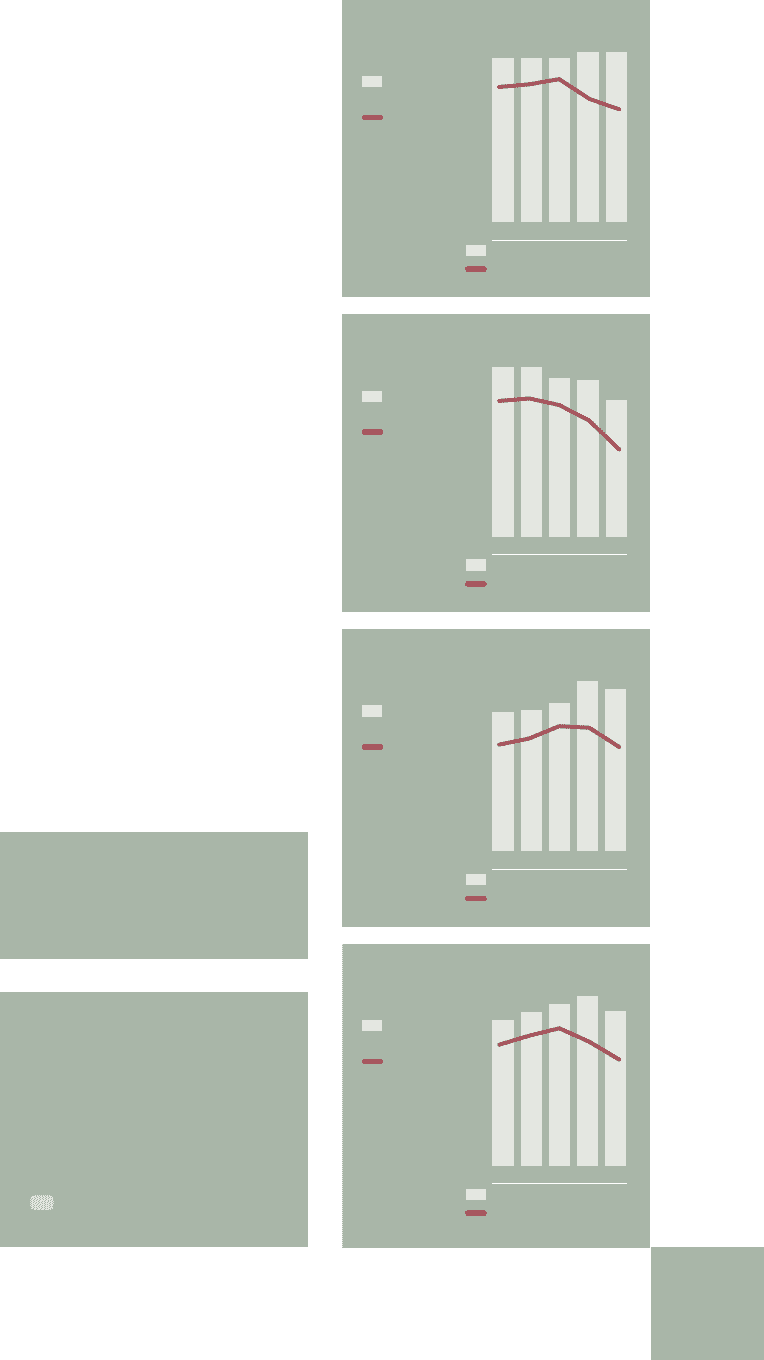

Energy consumption/

net sales has been

reduced by 13%

in 2005.

Energy consumption

Energy, TWh

Energy/net sales

MWh/SEK M

2.6 2.6 2.6

14.3 14. 5 14. 9

2.7

13.4

2.7

11. 6

01 02 03 04 05

Water consumption/

net sales has been

reduced by 24%

in 2005.

Water consumption

Water, Mm3

Water/net sales

m3/SEK M

9.2 9.2 8.6

50.9 52.0 49.1

8.5

42.2

7.4

32.1

01 02 03 04 05

Hazardous waste/

net sales has been

reduced by 17%

in 2005.

Hazardous waste

Hazardous waste, k ton

Waste/net sales

kg/SEK M

20.3 20.5 21.6

112 116 124

24.7

123

23.6

102

01 02 03 04 05

Solvent emissions/

net sales has been

reduced by 17%

in 2005.

Solvent emission

Emissions, k ton

Emission/net sales

kg/SEK M

1.8 1.9 2.0

10.1 10.7 11.2

2.1

10.3

1.9

8.5

01 02 03 04 05

Detailed environmental data from all

Volvo Group plants is available on

page 153.

➡