Volvo 2005 Annual Report Download - page 41

Download and view the complete annual report

Please find page 41 of the 2005 Volvo annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

Volvo Group 2005 37

Emissions from highway

transports in the EU

Sharply reduced emissions

0

20

40

60

80

100

120

1995 2000 2005

CO

VOC

NOx

Benzene

PM-diesel

Source: ACEA

CO

SO2

2

ations include the L60E-L330E wheel loaders,

Volvo FH 12 and Volvo FM 12 trucks with Euro

3 engines, the Volvo 8500 articulated bus and

the Volvo 8500 low-entry bus. Preparations

are under way in North America to attach envir-

onmental declarations to one model each from

Mack Trucks and Volvo Trucks.

The declarations consist of three parts: pro-

duction, use and scrapping. The basic principle

is that each new product must cause less envi-

ronmental impact than the product it replaces,

which sets rigorous environmental require-

ments for the development of new products.

Designers have access to a number of differ-

ent tools for deciding which materials, designs

and production processes have the least

impact on the environment.

The “Production” section describes aspects

such as energy consumption, emissions and

waste, while the “Use” section gives details

of fuel consumption, emissions and the use

of spare parts. The third section deals with

scrapping. The Group’s products are recyc-

lable to a large extent. And as much as 95%

of s om e t ru c ks c a n b e re co ve re d . D is a ss em bl y

ma nuals are ava ilab le as an a id in the rec over y

process. The manuals describe the proce-

dur es for disma ntlin g tr ucks , a s we ll a s the

color-coding system for components, which

shows what mater ials they consis t of. Recov -

ere d ma teri als a re a lso reused in pr oduc tion.

Volvo Group’s internal environmental prize

for 2005 was awarded to Volvo 3P for a

technique for using color-impregnated plastic

in for example the front end of Volvo trucks,

wind deflector and other cab components,

instead of lacquering them. Using color-

impregnated plastic substantially reduces

both environmental impact and costs. Other

positive features are that the material saves

weight and is fully recyclable.

Reduced emissions

The Volvo Group primarily uses diesel engines

in its products, due to their high energy effi-

ciency and their potential for low emissions.

The main focus in development is on diesel

engines. Improved fuel efficiency is an effect-

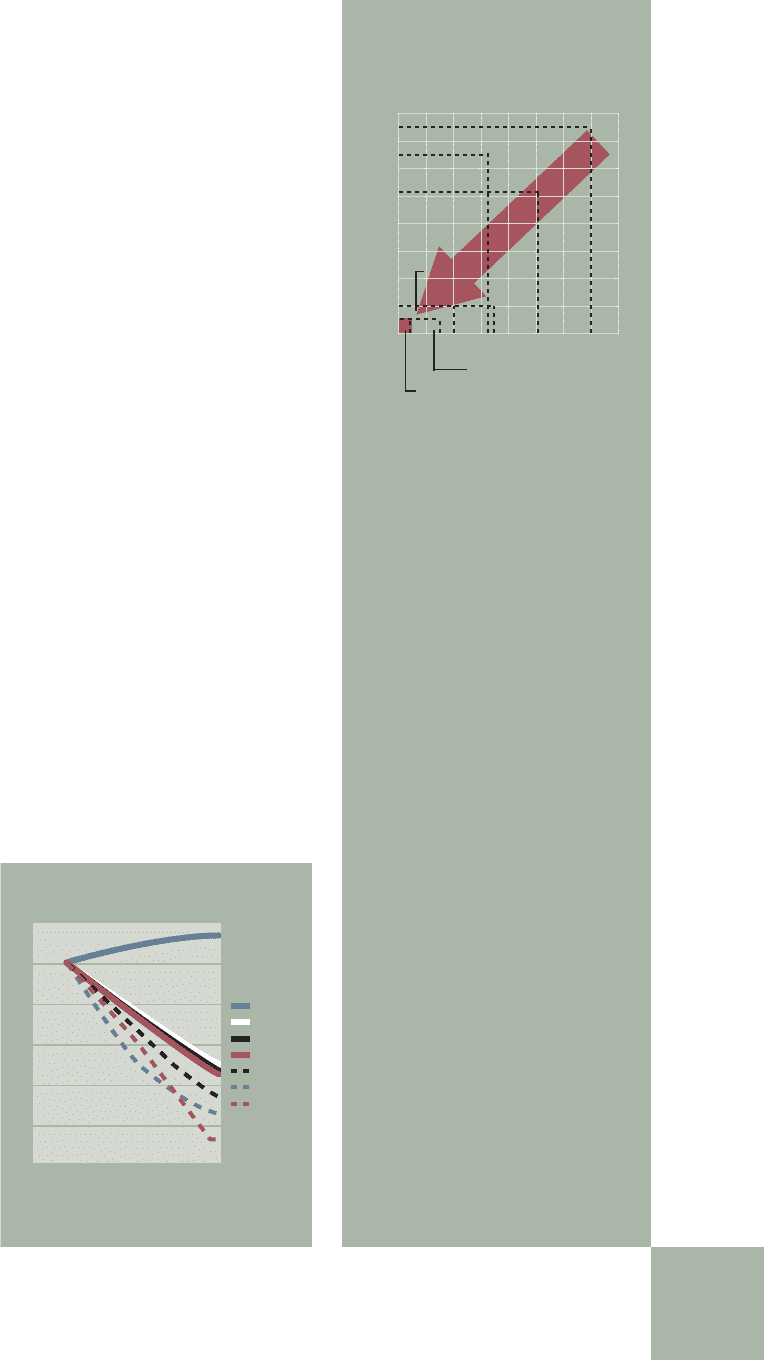

All heavy trucks and buses regis-

tered in the EU from October 1,

2006 must meet the Euro 4 emis-

sions standards.

There are significant differences

concerning exhaust emissions

between an engine fulfilling the cur-

rent Euro 3 requirements and one

that meets the Euro 4 requirements.

Emissions of nitrogen oxides (NOx)

have to be reduced from 5 to 3.5

g/KWh, corresponding to a reduc-

tion of 30%. Particle emissions (PM)

have to be reduced from 0.1 to 0.02

g/KWh, a reduction of no less than

80%. Euro 5, which will take effect

on October 1, 2009 will require that

NOx emissions levels in accordance

with Euro 4 be halved.

ive way of reducing carbon dioxide emissions,

as well as reducing costs for the Group’s cus-

tomers.

In order to improve air quality, regulators in

many countries are placing even more strin-

gent requirements on reducing emissions,

especially of nitrogen oxides and particulates.

In the US and the EU, among other places, the

requirements are set to become considerably

more rigorous during the next few years. For

more detailed information about future emis-

sions requirements, see the fact box on this

page.

To meet these requirements, the Volvo

Group is continuously developing new engine

technology to reduce fuel consumption and

emissions.

To fulfill the new requirements for trucks

and buses due to be introduced in Europe in

2006 (Euro 4) and 2009 (Euro 5), new solu-

tions are needed for diesel engines. The

Group’s solution to meet the requirements is

diesel engines with even more efficient com-

bustion and after treatment of exhaust gases

with the additive AdBlue and Selective Cata-

lytic Reduction (SCR). In North America, the

Volvo Group has chosen to use an exhaust

recirculation system – High-performance

Exhaust Gas Recirculation (HEGR) – to reduce

emissions of nitrogen oxides (NOx), combined

with a diesel particulate filter.

H o w a v e hi c l e i s d r iv e n a l so h a s a s i g ni f i c a nt

US 10, 2010

US 07, 2007

Emission standards

for trucks and buses

0.16

0.14

0.12

0.10

0.08

0.06

0.04

0.02

0.00

Particles, g/KWh

NOx, g/KWh

012345678

Euro 2, 1996

Euro 3, 2002

Euro 4, 2006

Euro 5, 2009

US 02, 2002