Volvo 2005 Annual Report Download - page 14

Download and view the complete annual report

Please find page 14 of the 2005 Volvo annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

...and continued

efficiency

enhancement...

10 Volvo Group 2005

Reduced costs

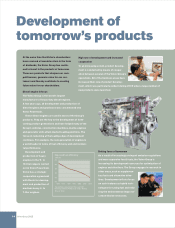

With the aim of reducing the costs of developing and manufacturing products, the Group

establishes systems and structures for the transfer of technologies and best practices.

Common production methods and internal processes are increasingly being used, which

creates flexibility and efficiency. In addition, the larger volumes make the Volvo Group an

attractive business partner, which increases the possibilities of attracting the best suppliers.

We are working on increasing the degree of shared components and utilizing shared mod-

ules. For example, Volvo Powertrain has developed two Group-wide engine platforms that

gradually will replace the previous 18 engine platforms. This will be occurring in pace with

the introduction of new products in the coming years. We are engaged in increasing num-

bers of Group-wide development projects, often in cooperation with selected suppliers.

Flexibility

An important task in the internal efficiency enhancement work is to achieve a more rapid

adjustment to fluctuations in the economy. This involves both the ability to increase pro-

duction and sales in upturns and to reduce them in economic downturns. This trend also

requires increased flexibility among suppliers.

Capital rationalization

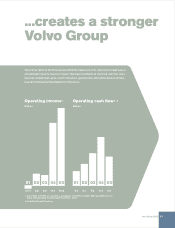

Since 2001, working capital turnover has been significantly improved, mainly for inventor-

ies and accounts receivable. In combination with the increased profitability, the capital that

has been released has created a strong cash flow, which has enabled the Volvo Group to

engage in product renewal throughout the entire business cycle. In the coming years work

in this area will focus on using sales and administrative resources more efficiently.