Volvo 2006 Annual Report Download - page 43

Download and view the complete annual report

Please find page 43 of the 2006 Volvo annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

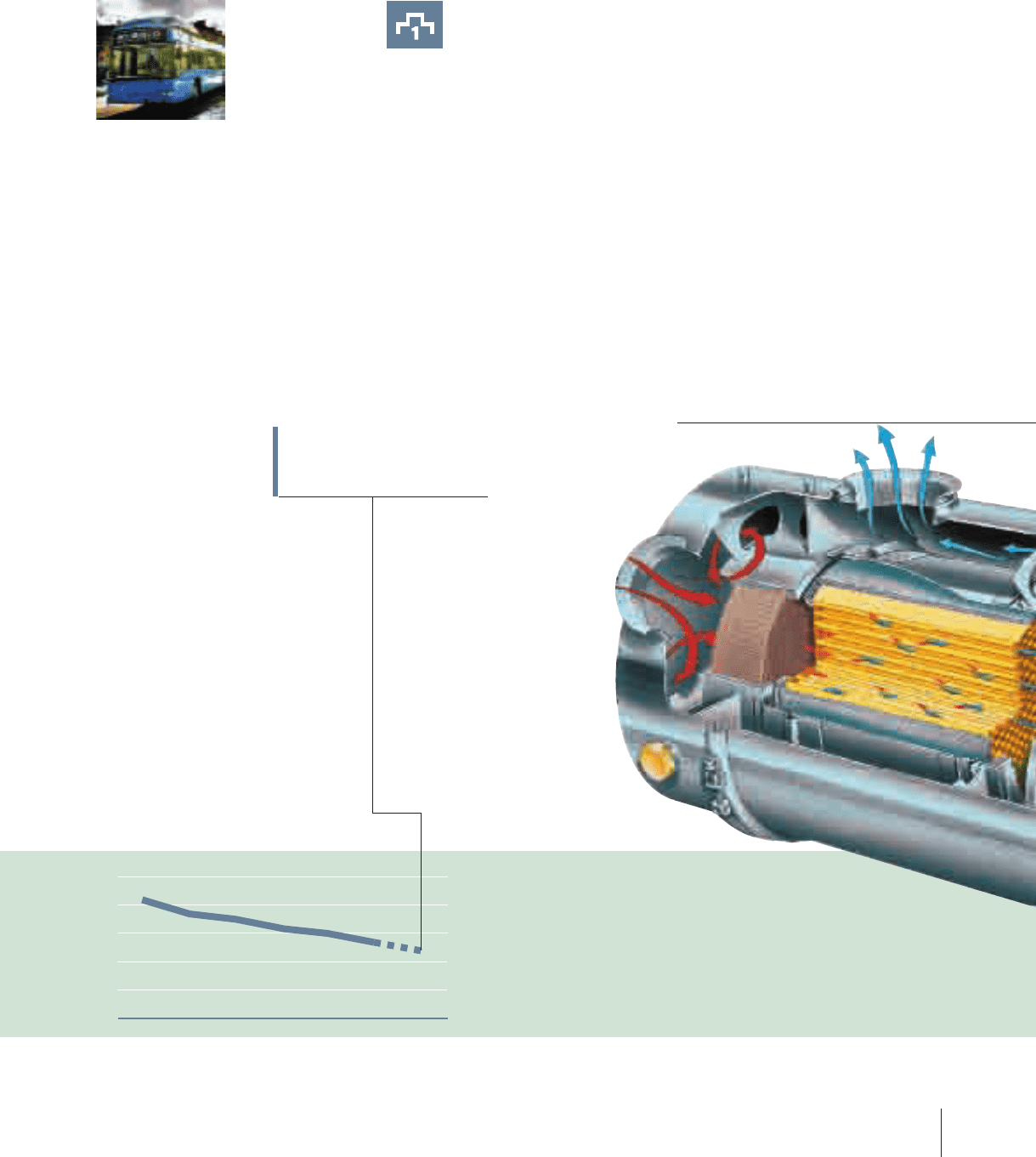

Hybrid technology

for heavy vehicles

In March, the Volvo

Group presented a

hybrid solution capa-

ble of producing up

to 35% energy savings in heavy vehicles. This

solution offers the highest fuel savings in situ-

ations in which the driver frequently brakes and

accelerates, for instance in urban bus trans-

port, urban distribution operations, refuse-col-

lection duties and construction operations.

Furthermore, the vehicle’s maintenance costs

can be lowered through reduced wear on the

brake system. The diesel engine in the hybrid

solution can also be powered by biofuels to

achieve carbon-dioxide neutral transport.

The Volvo Group is also involved in develop-

ing a new type of battery, Effpower, based on

the proven lead-acid tech-

nology used in today’s

starter batteries. The new

technology doubles the bat-

teries’ power output and their production cost

can be considerably reduced compared with

other available alternatives. Effpower can make

electric hybrids even more cost-effective.

More information

Visit www.volvo.com for more

information about Volvo’s environmental efforts:

policies, environmental information on products

and production, emission laws and educational

material.

Cross-section of a particulate trap. Using particulate

traps is one way of reducing emissions of particu-

lates.

Volvo’s Environmental Prize

awarded to three pioneers in

marine ecosystems

Volvo’s Environmental Prize for 2006 was

awarded to three distinguished scientists for

their research regarding human impact on

global fishing waters and marine environ-

ments.

The researchers, Professor Ray Hilborn of

the University of Washington in Seattle and

Professors Daniel Pauly and Carl Walters of

the University of British Columbia in Vancouver,

won the prize for developing analysis tools that

monitor the rapidly changing threats to marine

ecosystems.

Volvo’s Environmental Prize was introduced

in 1988 to support and acknowledge environ-

mental research and development, and has

become one of the world’s most prestigious

environmental awards.

The prize money of SEK

1.5 M is aw arded by

the Foundation

of The Volvo Environmental Prize.

1980 1985 1990 1995 20002005 2010

0

Source: Volvo

10

20

30

40

50

Development of fuel

consumption, Volvo truck

model FH12, 40 tons.

Decreased fuel consumption, l/100 km

The Volvo Group’s engines

are becoming increasingly

fuel efficient.

Internal Environmental Prize awarded to

Volvo Trucks North America

The Volvo Group’s Internal Environmental Prize

was awarded to a group of employees at Volvo

Trucks North America for several environment-

enhancing initiatives at the truck plant in New

River Valley, Virginia.

The winning team comprised Stephen

Pierett, Michael Kijak, Frank Stanley, Channon

Maycock, Danny Arnold and Thomas Newcomb.

Thanks to the team’s efforts, the water used for

testing operations was reduced by half between

2003 and 2005 and a system for recycling pro-

cess water was installed. Through automatic

lighting, automation and control of the build-

ing’s heating and cooling system, energy con-

Sustainable development 2006 39