Volvo 2006 Annual Report Download - page 39

Download and view the complete annual report

Please find page 39 of the 2006 Volvo annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

ational responsibility. All production facilities

have environmental coordinators. Issues relat-

ing to emission levels, fuel consumption and

choice of materials are handled by the develop-

ment departments in the respective business

areas and the Group-wide development units.

Every business area has an environmental

manager. The Volvo Group also has internal

consultants with specialized expertise in areas

such as chemicals, life cycle assessments,

environmental audits and environmental pro-

tection.

Environmental targets

The Group’s environmental targets are used

for follow-up purposes throughout the organi-

zation and are closely linked to its business

plans. The Volvo Group’s environmental targets

can be summarized in the following environ-

mental challenges.

The challenges facing production are:

• Reducing energy consumption by 50% per

produced unit by 2008 compared with 2003

• Doubling the use of carbon-dioxide neutral

energy by 2008 compared with 2003

• Terminating all use of oil and coal for the heat-

ing of facilities.

Challenges regarding product use:

• Achieving high fuel efficiency and low emis-

sions throughout product life cycles

• Measuring against the best

• Consistently carrying out activities to become

the industry leader

• Producing environmental data for follow-up

and communication for each new product

developed

• Implementing a strategy for tomorrow’s fuels

• Including alternative fuels and alternative

drivelines in product plans.

In production

Volvo Group has production facilities on every

continent, ranging from state-of-the-art, highly

automated factories to small-scale produc-

tion.

Regardless of size and location, all produc-

tion units must meet the Group’s minimum

requirements for environmental performance.

These requirements include guidelines for

chemical use, energy consumption, air and

water emissions, waste management, environ-

mental organization and improvement efforts.

If local laws and regulations are more compre-

hensive than the Group’s requirements, they

must be followed. Most factories meet the

requirements by a wide margin and are show-

ing constant improvement.

Regular environmental audits

Since 1989, Volvo has been carrying out envir-

onmental audits to ensure that all the plants

comply with the Group’s environmental policy.

The Volvo Group has insurance coverage for

environmentally related damage to its immedi-

ate surroundings, for instance in the event of

unexpected emissions. Newly acquired com-

panies and properties are subjected to due

diligence examinations which, in addition to

financial and legal aspects, also examine envir-

onmental factors and risks.

Environmental

management system

Volvo’s Group-wide environmental policy is one

of the primary instruments for guiding Volvo’s

environmental efforts. This policy forms the

basis for the Group’s environmental manage-

ment system, strategies and targets, reviews

and measures.

The environmental policy states that the

Volvo Group’s environmental program shall be

characterised by a holistic view, continuous

improvement, technical development and effi-

cient use of resources. The policy is in turn bro-

ken down into strategies and targets for the

organization.

An environmental management system is a

tool for monitoring an organization’s specific

environmental impact. The Volvo Group’s first

system was certified in 1995. There are also

environmental management systems for other

parts of the value chain, such as product devel-

opment and marketing. At the end of 2006,

99% of the employees in the Group’s produc-

tion units were working according to certified

environmental management systems, primarily

ISO 14001:2004.

The environmental policy states a commit-

ment to expanding the Group’s environmental

program to include collaboration partners, for

instance suppliers and distributors. Environ-

mental demands on suppliers were introduced

in 1996 and are used as an integrated part of

the evaluation of suppliers and for follow-up of

various purchasing organizations.

Responsibility for environmental work at

production facilities is a normal aspect of oper-

Environmental responsibility

Environmental management is a cornerstone of the Volvo Group’s sustainable develop-

ment efforts. Environmental care is also one of the Group’s corporate values. Volvo’s

environmental work is long-term and methodical and has two clear targets: reducing

envir onmental impact from production, and reducing environmental impact from product

use.

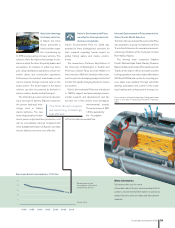

During 2007 windpower plants will be built adjacent

to the Volvo Trucks plants in Gent and Göteborg.

Sustainable development 2006 35