Volvo 2006 Annual Report Download - page 40

Download and view the complete annual report

Please find page 40 of the 2006 Volvo annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

Activities requiring a permit

All the Volvo Group’s production facilities have

the requisite envir onmental permits. In Sweden,

there are 16 facilities that require permits.

These permits encompass waste, noise and

emissions into the air, ground and water. One

Swedish environmental permit was renewed

in 2006, and four permits are due for renewal

in 2007.

Environmental care right from the start

The Volvo Group manufactures a

large number of products with

varying environmental impact.

Whatever the product, environmental care is

considered right from

the product develop-

ment stage. Life cycle

analyses provide a

complete picture of

the Group’s products’

environmental impact

throughout their life-

span, from raw material

to waste.

Life cycle analyses of the Group’s products

show that almost 90% of their total environ-

mental impact from carbon-dioxide and other

emissions from fossil fuel combustion occur

during their use.

Environmental declarations are produced to

describe the environmental impact from some

of the Group’s key products. These declar ations

consist of three parts: production, use and

Volvo Construction Equipment decided to

invest SEK 150 M in a new paintshop at its facil-

ity in Hallsberg. The new paintshop will lead to

better quality, higher capacity, reduced costs

and many environmental improvements. Solv-

ent emissions will be halved, greenhouse emis-

sions will be dramatically reduced through

lower fuel consumption, and considerably less

waste will be generated. The new paintshop will

have its own treatment plant, which will more

than halve the discharge of water to the munic-

ipal treatment plant despite increased produc-

tion volume.

Volvo Trucks’ cab factory in Umeå imple-

mented further environmental initiatives during

the year. For instance, plastic parts will be

painted in a new paintshop to reduce the total

environmental load. This initiative will cost SEK

scrapping. The basic principle is that each new

product must cause less environmental impact

than the product it replaces, which

sets rigorous environmental requirements for

the development of new products.

The “Production” section describes aspects

such as energy consumption, emissions and

waste, while the “Use” section provides details

of fuel consumption, emissions and the use of

spare parts. The third section deals with scrap-

ping. The Group’s products are recoverable to a

large extent. For instance, up to 95% of some

trucks can be recovered. Recovered materials

are also used in production.

Environmentally adapted production

Environmental protection and respon-

sible utilization of natural resources are

obvious aspects of all production. During

the year, Volvo Trucks decided to make

its automotive facility in Gent carbon-

dioxide neutral. Today, the facility is pri-

marily heated with natural gas. Three

windpower plants and a new biofuel

plant, that will be carbon-dioxide neutral, will

be built adjacent to the facility to provide it

with electricity and heating. In 2005, Volvo

Trucks launched its first carbon-dioxide neutral

facility in Tuve, Göteborg. In Göteborg and in

Gent long-term agreements on delivery have

been made with the respective energy supplier,

who will invest in the windpower plant. Volvo

Trucks’ facility in Umeå will also be made car-

bon-dioxide neutral, and the aim is for more

production facilities to follow suit.

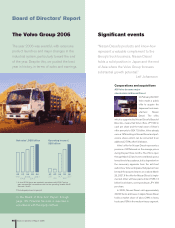

Hazardous wasteWater consumption

2.7

05

2.6

06

2.6

03

2.6

Energy, TWh

Energy/net

sales MWh/

SEK M

Energy consumption/

net sales has been

reduced by 9%

in 2006.

02

2.7

11. 6 10.514.914.5 13.4

04

7.4

05

7.6

06

8.6

03

9.2

Water, Mm3

Water/net

sales m3/

SEK M

Water consumption/

net sales has been

reduced by 5%

in 2006.

02

8.5

32.1 30.649.152.0 42.2

04

23.6

05

27.0

06

21.6

03

20.5

k ton

Waste/net

sales kg/

SEK M

Hazardous waste/

net sales has

increased by 7%

in 2006.

02

24.7

102 109124116 123

04

Volvo’s new diesel engines are leading in terms of

fuel efficiency.

Energy consumption

36 Sustainable development 2006