Volvo 2006 Annual Report Download - page 30

Download and view the complete annual report

Please find page 30 of the 2006 Volvo annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

INTERVIEW UNIFORM

POWER

the world’s second largest company in its sec-

tor. Similarly, it was no small task to reorganize

the entire operation, while simultaneously

delivering annual volumes amounting to

200,000 engines and 80,000 gearboxes.

“We are t h e world’s l a rgest producer of heavy

diesel engines, from 9 liters up to 18 liters. Our

aim is to lead development in terms of perform-

ance, quality and environmental characteris-

tics, and to deliver our products at competitive

prices, ” explains Lars-Göran Moberg.

The driveline, which consists of the engine,

gearbox and the driveshaft or driveshafts, is

often described as the heart of a vehicle. Volvo

Powertrain is responsible for the development

and production of heavy engines, gearboxes

and driveshafts. The business unit is also

responsible for ensuring that the Volvo Group is

supplied with medium-heavy engines, which

come from partner company Deutz, in which

the Volvo Group holds 7 percent interest.

Powertrain is also a substantial manufac-

turer of heavy gearboxes in-house, with pro-

duction in Köping, Sweden and Hagerstown,

Maryland, in the US . Extensive efforts have a lso

been made in this area to standardize develop-

ment, purchasing and manufacturing, while

concurrently broadening the customer offer-

ing. Since its introduction in 2002, Volvo’s

internally produced AMT gearbox has grown

rapidly in volume at the cost of manual gear-

boxes. In practice, it is the industry standard in

Europe and was recently launched in North

America.

Common engine platforms

To date, increased volumes have been the driv-

ing force for profitability at Volvo Powertrain.

The decision to work toward two platforms is

aimed at further strengthening the business

area in the future, although the strategy gave

rise to costs during 2006 for both the new and

the old generation of engines, since both were

being produced in parallel for a while.

“We see considerable advantages in the

increased volumes and the concentration to

two platforms regarding costs for quality and

delivery precision,” says Lars-Göran Moberg.

The new platforms will further increase

economies of scale, since the Volvo Group

works with a common architecture and shared

technology. But Lars-Göran Moberg empha-

sizes that, despite this, the range of choices for

customers is larger than before.

The Volvo Group’s engine offering is one of

the broadest in the market, and engines are

adapted to the size of vehicles, what type of

transport work they will be doing, as well as the

environment in which the product is to operate.

“We develop and produce engines with differ-

ent characteristics, but based on common archi-

tecture and shared technology. The truck brands

will always retain their distinctive brand identity,

and the same applies to the engines. The most

important point for the customers is that we

produce drivelines that are optimized for the

transport work to be done by the specific ve -

hicle, combined with lower fuel consumption

and better operating characteristics. As a re sult

of the common engine strategy, Volvo Con-

struction Equipment and Volvo Penta also have

a solid competitive advantage with regards to

forthcoming emissions standards,” says Lars-

Göran Moberg.

Several advantages

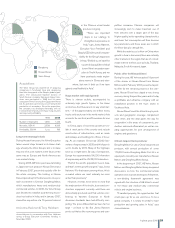

The Volvo Group’s structure, with a common

business unit for the development, production

and purchase of drivelines, has several advan-

tages. Volvo Powertrain has concentrated its

expertise in research and development to spe-

cialized units in Sweden, France, the US and

Brazil. The division of labor is clear and there is

extensive cooperation between the units. The

joint focus on a platform creates synergies and

resources that help to improve the driveline’s

performance and cost-efficiency.

The production structure has also been

overhauled. Previously there were three differ-

ent industrial systems. Now there is a single

common system designed to achieve econ-

omies of scale, high quality and delivery reli-

ability, within which the four sister plants in

Göteborg, Lyon, Hagerstown and Curitiba sup-

ply their local markets with heavy engines and

heavy gearboxes.

Volvo Powertrain has also concentrated its

Lars-Göran Moberg

Lars-Göran Moberg, born 1943, holds a Masters

degree in Engineering and has been President of

Volvo Powertrain since 2001. He is also Board

Chairman of Volvo 3P and Volvo Technol ogy and

Technical Director of AB Volvo. He has worked for

Volvo since 1995 and has been a member of

Volvo’s Group Executive Committee since 2001.

purchasing – from nearly 700 suppliers a few

years ago to slightly more than 80 today. Those

that have been selected now have the capacity

to participate more actively in the development

process.

“It should also be borne in mind that we

implemented all these changes and develop-

ment projects at the same time as we were inte-

grating three formerly separate powertrain div-

isions,” says Lars-Göran Moberg. “Today, we

are a global organization with a coordinated

industrial structure, a common supplier struc-

ture a n d common platforms. Now we must make

sure that we get the maximum out of the new

product range and the new industrial system.”

Emissions requirements one

of the challenges

Lars-Göran Moberg identifies tougher emis-

sions legislation and changed customer re -

quirements as future challenges.

Lower fuel consumption is becoming in-

creasingly important both from an environmen-

tal viewpoint and from a commercial perspec-

tive, with fuel accounting for an increasingly

large proportion of operating costs. There are

several key steps along the way toward cleaner

engines f o r trucks and b u ses. The Euro 4 s t and-

ard was introduced in October 2006, and Euro 5

is planned for 2009. On January 1, 2007, the

US’07 standard came into force in the US. The

standard drastically reduces emissions levels

compared with only a year ago. A final step

towards ne ar zero emissions will be taken when

US’10 and Euro 6 will come into force in 2010

and 2012/2013 r espectively, according to plan.

26 A global group 2006