Volvo 2006 Annual Report Download - page 26

Download and view the complete annual report

Please find page 26 of the 2006 Volvo annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

INTERVIEW

&

&

DEVELOPMENT

SYNERGIES

&

SYNERGIES

&

further, due to the fact that the Volvo Group has

such a high volume of important components

that major suppliers want to cooperate and are

offering excellent conditions. And, the volumes

are likely to increase, since the Volvo Group and

Nissan Diesel have commenced purchasing

cooperation.

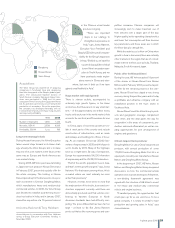

Global organization

Volvo 3P’s head office and global development

center is located in bright, airy premises adja-

cent to the Volvo Trucks plant in Lundby,

Göteborg, but the organization is global with

more than 2,900 employees and 600 consult-

ants in eight offices on five continents.

“It is important to be established in close prox-

imity to truck operations,” stresses Torbjörn

Holmström. He believes that it is also crucial

that in formation an d knowledge are exchanged

freely between the various countries.

“We have taken the best expertise in terms

of development of various truck types from the

three truck companies and important ingredi-

ents such as quality and cost efficiency and

learned from each other.”

And, the one thing he would like to specific-

ally highlight is the company culture, in which

nothing is regarded as an obstacle, but instead

assistance and support is provided to each

other to jointly create solutions that contribute

to strengthening the position of the Volvo

Group.

What are the major challenges facing Volvo

3P?

“The simple response would be to point to all

the products that are being developed and that

will comply with future demands in terms of

environmental laws. Today, jointly with Volvo

Powertrain, we look at what must be delivered

between 2010 and 2013. However, crucial to

our success is that we must successfully con-

tinue developing the intellectual capital and

stimulate exchange of thoughts and ideas,”

says Torbjörn Holmström.

horizon. This is to ensure that the Group has the

correct products in the long term and to coord–

inate technology and components between

truck brands.

“We implement rolling eight-year plans for

products and a ten-year plan for technology

development. But the plans are not written in

stone, they are adapted each year to changes

in the Volvo Group and the environment. There

is a list of what the Group would like to imple-

ment and it is a question of distributing re-

sources to the correct projects,” says Torbjörn

Holmström.

Bulk purchasing generates lower costs

To date, purchasing is the area in which coordi-

nation gains have been most significant. The

Volvo Group has considerable size and pur-

chasing power when negotiating purchasing

contracts with suppliers. In the past year, the

focus was on the significant increases in the

prices of raw materials such as steel and other

metals, rubber and plastic.

Torbjörn Holmström feels that by implement-

ing global purchasing and larger volumes, price

increases were handled in a satisfactory man-

ner. He also stated that in the past years pur-

chasing was concentrated to fewer strategic

suppliers.

An increased portion of joint technology and

components also means positive effects in

terms of purchasing, in which one selected

supplier receives increased volume b a se, w h ich

results in lower production costs and improved

coverage of development costs.

“We have reduced the number of suppliers

from 2,500 to around 1,500. We have also

reduced purchasing costs, and my opinion is

that we a re just as e ff ective as those companies

that are regarded as the strongest purchasers

in the market”, says Torbjörn Holmström.

Are there any gains left in purchasing?

Torbjörn Holmström believes that there are

possibilities to improve purchasing conditions

Efficient product development

In terms of the number of employees, product

development is Volvo 3P’s largest area. Nearly

2,300 employees work in close collaboration

with the three truck brands and Volvo

Powertrain. Volvo 3P concentrates on chassis,

cabs and electrical systems, while Volvo

Powertrain works on the driveline, meaning the

engine, gearbox and the rear axle.

The work is based on common architecture

and shared technology between the truck

companies. This offers many advantages.

Resources such as expertise, time and capital

can be combined to produce a joint solution to

a difficult technical problem, instead of distrib-

uting resources for three different alternatives.

This strengthens the motivation to invest

resources in developing optimum solutions for

each truck model based on the customer’s

requirements.

“A truck contains a large number of compon-

ents that are common in all trucks and this

applies to the driveline as well as the work we

do. This produces improved quality and lower

costs, which is advantageous to our customers.

Development resources are also released to

develop truck models that are even more opti-

mized for different types of transports, by

adapting solutions to each brand core seg-

ment. It is vital to remember that Volvo 3P is

there to strengthen each brand, not to dilute it,”

says Torbjörn Holmström.

This is why there are distinct definitions for

the souls of the different brands, in terms of

appearance, cabs, interior fittings, engines and

driving performance. A truck from Volvo must

naturally feel like a Volvo just as there are dis-

tinct vehicles from Renault Trucks and Mack

Trucks.

Product planning for the future

When product development is about producing

the correct products for l aunching within one o r

a few years, product planning has a long-range

22A global group 2006