Konica Minolta 2015 Annual Report Download - page 52

Download and view the complete annual report

Please find page 52 of the 2015 Konica Minolta annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

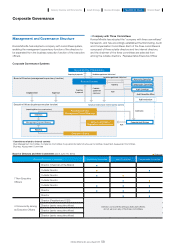

The value chain supporting growth

To produce high added-value products and services, Konica Minolta has built a value chain supporting

everything from development to procurement, production, distribution, marketing and sales, and after-sales

support. Alongside leveraging this value chain to optimize costs, we are also working to improve quality,

reduce environmental impact, and develop the people who make it all possible.

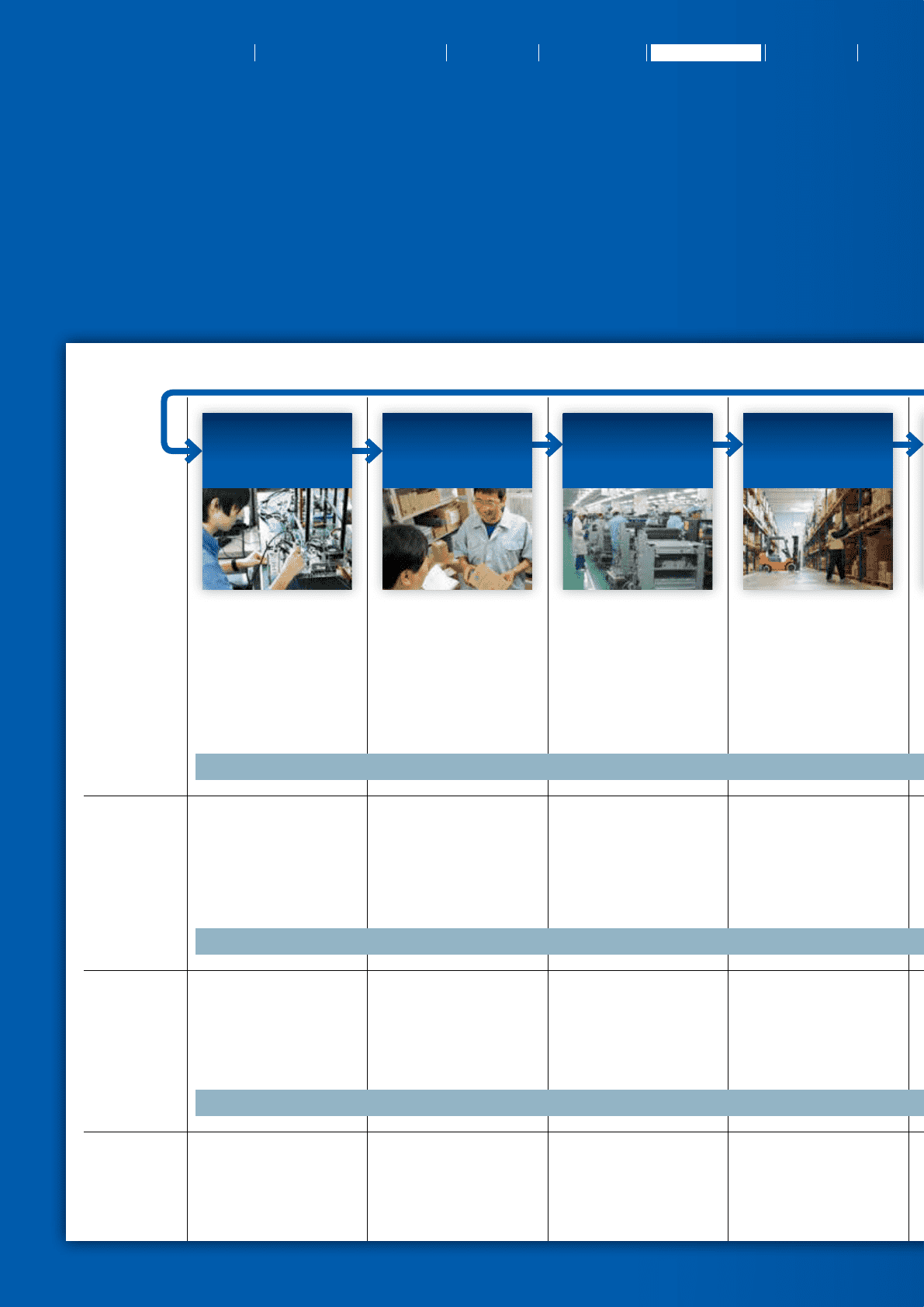

Value Chain

Quality

Improvement

Initiatives

• Utilize the four core technologies

of materials, optics, nanoscale

fabrication, and imaging to

develop revolutionary products

• Mitigate procurement quality risk

through supplier diversification

• Work with business partners to

conduct quality improvement

activities

• Improve quality and avoid the risk

of overconcentrating production

sites in China by developing

additional production facilities in

ASEAN

• Share quality issues and

cross-deploy countermeasures by

conducting Production Capability

Assessments

• Improve and maintain logistics

quality (improve lead times and

reduce damage and losses) through

KPI management in cooperation

with logistics (shipping and

inventory) partners (contractors)

• Conduct logistics network design

and respond flexibly to reduce

logistics risks (freight congestion

caused by natural disasters,

government policies, conflicts, etc.)

•

Environmental

Initiatives

• Create the green products that

customers and society need

• Develop the environmental

technologies for creating green

products

• Work with business partners to

promote the Procurement

Collaboration activities for

ongoing mutual improvement of

business environments

• Work with business partners to

conduct green supplier activities

and reduce environmental impact

and costs

• Conduct green factory operations

that simultaneously reduce

environmental impact and cut costs

• Conduct upgrade recycling (using

upgraded recycled materials) to

solve regional environmental issues

• Reduce CO2 emissions through

better logistics efficiency

• Make packaging smaller and

lighter

•

•

Human

Resource

Initiatives

• Hold the Challenge Engineers

Forum to develop young

technicians

• Develop technology management

staff (MOT education)

• Provide intellectual property

education in China, where patent

acquisition is heating up

• Improve skills through personnel

rotation in and outside of Japan

• Conduct Product Safety

Education to improve awareness

and technologies aimed at

product safety

• At production sites, conduct

activities for building well-rounded

people and provide safety and

health education

• Strengthen logistics strategy

planning ability aimed at overall

optimization

• Strengthen ability to execute

when building a distribution

network

•

Cost Initiatives

• Acquire patents in Japan, the

U.S., China, and other countries

• Invest at least 70 billion yen

annually in R&D

• Work with business partners to

control costs, beginning at the

development stage

• Conduct efficient global

procurement activities that

account for logistics, exchange

rate volatility and other factors

• Achieve highly-efficient

production through digital

manufacturing (ICT, automation)

• Introduce universal production

processes by using modules

• Reduce costs by improving

shipping efficiency (improving

container/truck loading efficiency)

• Optimize inventory and improve

shipping efficiency through

optimal placement of distribution

facilities

•

Human Resource Management (pg. 58)

Environmental Management (pg. 57)

Quality Management (pg. 56)

R&D

P.53

Procurement

P.54

Production

P.54

Distribution

P.54

51

KONICA MINOLTA, INC. Annual Report 2015

Foundation for GrowthBusiness StrategiesGrowth StrategyCompany Overview and Characteristics Financial Report