Volvo 2013 Annual Report Download - page 50

Download and view the complete annual report

Please find page 50 of the 2013 Volvo annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

EFFICIENT PRODUCTION AND RESPONSIBLE SOURCING

Cornerstones of the Group’s

manufacturing operations

Environmental, economic and social sustainability is a long-standing cornerstone of the Volvo Group

business. We have adopted and developed tools, processes and production systems to help us set a

global standard of excellence and guide our employees on responsible behavior.

Global standards

An important tool is the Volvo Production Sys-

tem (VPS), which is used for many processes

throughout the organization, including product

development, business services and logistics.

VPS is a way of working with the minimum re -

sources necessary, and using methods that

streamline operations and minimize productivity

losses. It includes tools for measuring and improv-

ing workplace safety, health and well- being.

As employees infl uence the quality of prod-

ucts and services we deliver, transparency and

clear communications with cross-functional

teams are equally important aspects of VPS.

Quality, safety and environmental care are

our corporate core values and are embedded in

our sustainability approach. At each production

unit, we have quality coordinators, safety dele-

gates and environmental coordinators, and we

measure, monitor and continuously improve our

performance.

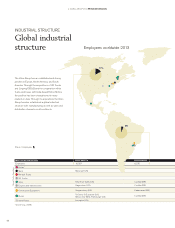

The Volvo Group conducts manufacturing in

18 countries worldwide. All production facilities

comply with prevailing legislation and our mini-

mum requirements for environmental manage-

ment and improvement, chemicals, energy con-

sumption, emissions to air and water, and waste

management. To ensure compliance, environ-

mental audits have been conducted group-wide

since 1989.

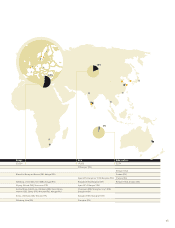

All our wholly-owned production sites have

certifi cation for the ISO 9001 quality manage-

ment system. 94% of our production is certifi ed

in accordance with the ISO 14001 environmen-

tal management standard and 37% in accord-

ance with the OHSAS 18001 international

standard for occupational health and safety.

The Group’s New River Valley plant in Virginia

and Macungie plant in Pennsylvania, U.S., have

both gained ISO 50001 certifi cation – the leading

international certifi cation program for driving

continuous improvements in energy effi ciency.

Both plants are also certifi ed to the top U.S.

energy specifi cation – the Superior Energy Per-

formance (SEP).

In 2013, there were 15 licensable facilities in

Sweden. There is a continuous review of the envi-

ronmental permits, but no environmental permits

need to be renewed in 2014. During the year,

there were no major environmental incidents.

Energy effi ciency

Our ambitions to increase energy effi ciency

and attain carbon neutrality are important both

in terms of environmental and economic sus-

tainability. The Volvo Group was the fi rst auto-

motive manufacturer to participate in the WWF

Climate Savers program. Since 2009, we have

reduced carbon emissions from our operations

by 13%. This is already in excess of the 12% tar-

get we are committed to achieving by 2014.

Focusing on energy saving has a clear im pact

on the Group’s fi nancial results. For example, at

our cab paintshop in Blainville, France, an energy

reduction plan saved 320,000 euros between

2011 and 2013, equating to an average annual

reduction of 4,513 MWh of energy and a 1,170

ton reduction in CO2 emissions.

Carbon-neutral manufacturing

Volvo CE’s factory in Braås, Sweden, was certi-

fi ed carbon neutral at the end of December

2013, becoming the fi rst construction equip-

ment production facility in the world to be pow-

ered entirely by renewable energy. This was the

culmination of collaborative efforts that began

back in 1999 and involved the local energy

A GLOBAL GROUP 2013 BUSINESS MODEL

Our Braås factory in Sweden is the world’s fi rst carbon-neutral production facility for construction equipment.

46