Volvo 2014 Annual Report Download - page 52

Download and view the complete annual report

Please find page 52 of the 2014 Volvo annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

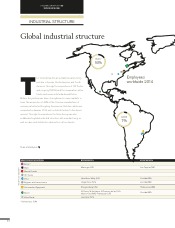

Cornerstones of the Group’s

manufacturing operations

Environmental, economic and social sustainability is a

long-standing cornerstone of the Volvo Group business. We

have adopted and developed tools, processes and production

systems to help us set a global standard of excellence and guide

our employees on responsible behavior.

Global standards

An important tool is the Volvo Production System (VPS), which is

used for many processes throughout the organization, including

production, product development, logistics and administration.

VPS is a way of working with the minimum resources necessary,

and using methods that streamline operations and minimize pro-

ductivity losses. It includes tools for measuring and improving

workplace safety, health and well-being.

As employees infl uence the quality of products and services

we deliver, transparency and clear communications with cross-

functional teams are equally important aspects of VPS.

Quality, safety and environmental care are our corporate core

values and are embedded in our sustainability approach. At each

production unit, we have quality coordinators, safety delegates

and environmental coordinators, and we measure, monitor and

continuously improve our performance.

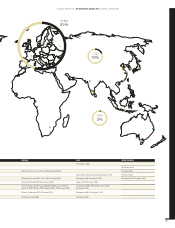

The Volvo Group conducts manufacturing in 19 countries

worldwide. All production facilities comply with prevailing legisla-

tion and our minimum requirements for environmental manage-

ment and improvement, chemicals, energy consumption, emis-

sions to air and water, and waste management. To ensure

compliance, environmental audits have been conducted group-

wide since 1989.

All our wholly-owned production sites have certifi cation for the

ISO 9001 quality management system. 98% of our production is

certifi ed in accordance with the ISO 14001 environmental man-

agement standard. There was a new health and safety organiza-

tion implemented during 2014 with the purpose to implement the

Volvo Group minimum requirements for the area. The focus is to

establish networks within the Volvo Group to work with health and

safety both from an operational and strategic level.

More than 94% of our automotive products spend is with ISO

14001 or equivalent-certifi ed suppliers.

Carbon-neutral manufacturing

The long term objective is that all plants in the Volvo Group should

be CO2 neutral and there is an on-going work to reach this objec-

tive. Volvo CE's factory in Braås, Sweden was the fi rst construction

equipment production facility in the world to be powered entirely

by renewable energy in 2013. Already in 2007, the Volvo plant in

Ghent, Belgium was the fi rst truck plant to set the standard for

carbon-neutral truck manufacturing.

In November 2014, the Group’s New River Valley (NRV) plant in

Virginia, US, became carbon neutral in its electricity use. All elec-

tric power for the plant is now generated by methane gas from 13

landfi lls in the region. This is the latest milestone in the NRV

plant’s commitment to sustainability. Together with the Macungie

plant in Pennsylvania and the Hagerstown plant in Maryland, the

NRV plant's energy conservation efforts have been recognized

with certifi cation under both ISO 50001 standards and the U.S.

Department of Energy’s Superior Energy Platinum (SEP) program

– the top international and U.S. certifi cations for driving continu-

ous improvements in energy effi ciency.

Licensable facilities in Sweden

In 2014, there were 15 licensable facilities in Sweden. The per-

mits cover the general conditions for the operations such as the

allowed production volumes and the environmental performance.

All permits have specifi c site requirements set for e.g. emissions

to the air, emissions to water and noise levels, all of which would

have an impact on the neighbors and the environment. There is a

continuous review of the environmental permits, but no environ-

mental permits need to be renewed in 2015. During the year,

there were no major environmental incidents.

A GLOBAL GROUP 2014

BUSINESS MODEL

EFFICIENT PRODUCTION AND

RESPONSIBLE SOURCING

Volvo Production System (VPS) and Operational

Development (OD) are aimed at:

• Improving processes

• Delivering results

• Developing people.

PRINCIPLES

48