Volvo 2014 Annual Report Download - page 51

Download and view the complete annual report

Please find page 51 of the 2014 Volvo annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

More effi cient logistics and spare-parts management

Within the Group's truck business there is an extensive logistics

operation responsible for all the fl ows of goods and products to

and from the Group’s production facilities as well as the supply of

spare parts. To increase effi ciency and delivery precision to end

customers, the structure is being reviewed in Europe, North

America and South Africa.

In Europe, the Group’s spare-parts warehouse in Ghent, Bel-

gium will increase, while Volvo CE’s central warehouse in Eskil-

stuna, Sweden will be scaled down and converted into a regional

warehouse for the Nordic market. At the same time, Eskilstuna

will take over the stock from Göteborg, which will be closed. In

North America, the management of spare parts with high turnover

rates will be brought to a new central warehouse in Byhalia, Mis-

sissippi, while the warehouse in Columbus, Ohio will handle spare

parts that are not used as frequently. This means that the three

warehouses in Atlanta, Dallas and Memphis will be discontinued

and the warehouses in Baltimore and Chicago will be signifi cantly

reduced. In South Africa, spare-parts management will be consol-

idated from three facilities into one.

Altogether, these changes mean an increased availability of

spare parts to our customers with 400 fewer employees and

lower costs.

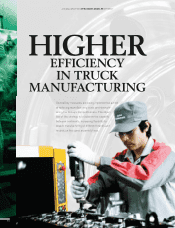

European Optimization Program

In Europe, truck manufacturing is being optimized through the

European Optimization Program, which consists of four structural

changes. The fi rst step was taken when manufacturing of medi-

um-duty Volvo trucks was relocated from Ghent, Belgium to

Blainville, France, which entailed that production of medium-duty

trucks for both Volvo and Renault Trucks was concentrated to one

plant. The second step was to optimize the assembly of heavy-

duty trucks for the Volvo brand by discontinuing one of two

assembly lines in Göteborg and optimizing the volumes between

the Göteborg and Ghent plants. The space that was freed up in

both Ghent and Göteborg is being used to facilitate a complete

implementation of the Volvo Assembly Concept and component

supply according to the fi shbone principle and thereby signifi -

cantly reduce logistics costs.

Finally, the cab trim operations in Umeå, Sweden will be relo-

cated to Göteborg during the second quarter of 2015, while the

plant in Umeå will focus even more on its main core operation –

metal stamping, welding and painting of cabs.

All in all, the changes mean that the fi nal assembly capacity will

be retained with fewer employees and reduced logistics costs.

Restructuring in Japan

In Japan, extensive changes are being implemented to focus the

operations on the domestic market, with associated adaptation of

volumes. The industrial capacity will be reduced to 13,500 trucks and

the operation will be concentrated to the main facility in Ageo. This

means that all non-core operations will be discontinued, unutilized

properties divested and old buildings and equipment will be disman-

tled. The workforce in Japan will be reduced to half the original size.

Additional restructuring

The measures also include discontinuing operations that have

been deemed too small to operate effi ciently. As a consequence

of this, the crank shaft plant in Leganes, Spain has been discon-

tinued and the volumes relocated to the facility in Skövde,

Sweden. Contract manufacturing of Renault Trucks in Karsan,

Turkey has been terminated and production of Renault Trucks’

new models has been concentrated to existing plants in France.

In addition, the Mack plant in Jacksonville has been closed and

manufacturing concentrated to the main facility in Macungie.

Group Trucks Operations has also discontinued the facilities for

remanufacturing components in Eslöv and Eskilstuna, Sweden

and moved the operation to Flen, Sweden and Ghent, Belgium to

better utilize existing capacity.

Continuous improvements

In parallel with reducing structural cost, there is signifi cant focus

on continuous improvements based on the Lean principle. During

2014, a number of sites were selected for a special initiative in

this area. The use of continuous improvement methodology will

increase in signifi cance over time to secure the long-term produc-

tivity progress in the Volvo Group. The pragmatic approach is to

let the different sites learn from each other and use the more

mature sites as mentors.

A GLOBAL GROUP 2014 BUSINESS MODEL EFFICIENCY

47