BMW 2013 Annual Report Download - page 71

Download and view the complete annual report

Please find page 71 of the 2013 BMW annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

71 COMBINED MANAGEMENT REPORT

In the short to medium term, the BMW Group is work-

ing on achieving additional fuel economy by deploying

a wide range of measures from the electrification of

the drivetrain through to hybrid solutions. Solutions for

sustainable mobility in densely populated areas are

also

in the process of being developed. Large-scale field

trials with the MINI E have been carried out in the UK,

Germany, France, the USA, China and Japan. A test fleet

of BMW ActiveE electric cars based on the BMW 1 Se-

ries Coupé has been on the road since 2011. The exten-

sive knowledge gained from the trials will be used in

the series development of the BMW Group’s electric cars.

The BMW i3 came onto the market in 2013 as the first

series-produced electric car made by the BMW Group

and specially designed for the metropolitan regions of

the world.

Similar to the statutory requirements being imposed

on car manufacturers to reduce fuel consumption and

emissions, the rules for car safety are also becoming

continuously tougher, such as crash specifications in the

USA. The specifications demanded of vehicles are chang-

ing

so comprehensively that there is no option but to

develop new technologies to improve both active and

passive safety systems. Active safety systems such as

suspension regulation and driver assistance systems

make an essential contribution to the prevention of ac-

cidents, while passive safety systems help to reduce the

consequences of accidents.

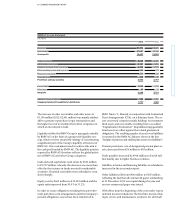

As in the previous financial year, the amounts of risk

attached to strategic and sector-specific risks are classi-

fied as low.

Operational risks

Production

Production stoppages and downtimes – in particular

due to fire, but also those attributable to manufacturing

equipment breakdowns, logistical disruptions or new

vehicle production line start-ups – represent risks which

the BMW Group counters with a broad range of

appro-

priate measures. Production structures and processes

are designed from the outset with a view to reducing

potential damage and the probability of occurrence. In

addition to technical fire protection measures, the BMW

Group has implemented an array of strategies, includ-

ing preventative maintenance, spare parts management

on a multi-site basis and back-up plans for alternative

transportation. The level of risk is also reduced by the

deployment of flexible work-schedule models and em-

ployee time accounts, but also by the ability to produce

specific models at additional sites if necessary. More-

over, risks arising from business interruption and loss

of production as a consequence of fire or natural disaster

are also insured up to economically reasonable levels

with insurance companies of good credit standing.

The level of risk attached to production interruptions is

classified as medium. There has been no change in this

assessment compared to the previous year.

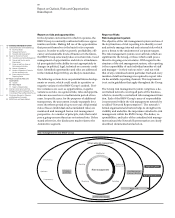

Purchasing

Close cooperation between carmakers and automotive

suppliers generates economic benefits on the one hand,

but also raises levels of dependency. The increasing

trend towards modular-based production

with a set of

common architectures covering various

models and

product lines exacerbates the consequences

of the loss

of a supplier or failure to supply on time. As

part of

the supplier preselection process, the BMW Group is

careful to ensure that its future business partners come

up to the same high ecological, social and

corporate

governance standards by which the BMW

Group is

generally measured. Suppliers are assessed on the basis

of the BMW Group Sustainability Standard which is

applied throughout the worldwide supplier network.

This set of fundamental principles and standards covers

both production and non-production aspects relevant

for the goods and services provided by suppliers, which

also includes compliance with internationally recog-

nised

human rights and applicable labour

and social

standards. The principal tool for ensuring

compliance

with the BMW Group Sustainability Standard is a three-

stage sustainability and risk management approach

comprising a BMW Group-specific sustainability risk fil-

ter, a sustainability questionnaire and a sustainability

audit. In addition, the technical and financial capabilities

of suppliers – especially those supplying for

modular-

based production – are continuously monitored

during

both the development and production phases of the

Group’s vehicles. Supplier sites are assessed

for expo-

sure to natural hazards, such as floods or earthquakes,

in order to identify supply risks at an early stage and im-

plement appropriate countermeasures.

Raw materials management procedures are in place to

mitigate the risk of a production interruption due to

shortages of supplies of critical raw materials. The supply

risk is also reduced by developing and implementing

systems governing minimum inventory levels.