BMW 2013 Annual Report Download - page 44

Download and view the complete annual report

Please find page 44 of the 2013 BMW annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

44

18 COMBINED MANAGEMENT REPORT

18

General Information on the BMW Group

24 Report on Economic Position

24 Overall Assessment by Management

24 General and Sector-specific

Environment

27

Financial and Non-financial

Performance Indicators

29 Review of Operations

29 Automotive Segment

35 Motorcycles Segment

36 Financial Services Segment

38 Research and Development

40 Purchasing

41 Sales and Marketing

42 Workforce

44 Sustainability

47 Results of Operations, Financial

Position and Net Assets

56 Events after the End of the

Reporting Period

63 Report on Outlook, Risks and

Opportunities

81 Internal Control System and Risk

Management System Relevant for

the

Consolidated Financial Reporting Process

82

Disclosures Relevant for Takeovers

and Explanatory Comments

85

BMW Stock and Capital Markets

Economic success, the responsible use of resources and

the assumption of our social responsibilities are the

cornerstones for long-term growth and a continual rise

in the value of the business. For this reason, due

con-

sideration to ecological and social criteria along the

entire value-added chain and a clear commitment to the

preservation of resources are values that are firmly em-

bedded in the philosophy of the BMW Group.

Again in 2013, the Group successfully maintained its

leading position among the most sustainable carmakers

worldwide – a fact borne out by the top places achieved

in prestigious ratings. The BMW share was again included

in the Dow Jones Sustainability Indices (DJSI, Europe

and World), making the BMW Group the only carmaker

to be consecutively listed in the top three for the last

15

years. In the Global 500 Rating of the Carbon Dis-

closure Project (CDP), in 2013 we achieved our best re-

sult of all time and with 100 out of 100 possible disclo-

sure points and a performance assessment in the best

‘A’ ranking, making us leaders in our sector.

More-

over, the BMW Group was again included in the British

FTSE4Good Index in 2013.

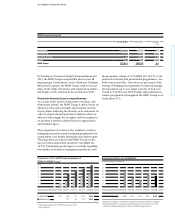

Clean production

The integration of environmental management in all

production processes enables us to minimise our use

of

resources and cushion their environmental impact.

Since 2006 we have reduced both the resources utilised

and the emissions per vehicle produced by an average

of 41.4 %.

The individual figures are as follows:

SUSTAINABILITY

Due to the increasing significance of contract production,

only vehicles manufactured at BMW production plants1

are taken into account to calculate environmental per-

formance indicators, since, looking forward, this is seen

as the best way to ensure a differentiated portrayal of

the resource efficiency of the BMW Group’s own produc-

tion

capacities.

In 2013, the utilisation of resources and the emissions

per vehicle produced were again reduced by an average

of 6.6 % compared with the previous year, thus giving

rise to savings of €6.8 million.

Despite extensive in-house production (e. g. CFRP manu-

facturing)

and the construction / commissioning of new

structures worldwide (such as the new foundry at the

Landshut plant), we managed to further reduce the

energy consumption per vehicle produced to 2.36 MWh

or 2.1 %. Improved energy efficiency, the utilisation of

highly efficient, ecologically sustainable combined heat

and power plants (CHPs) and the use of electricity

generated from renewable sources enabled us to reduce

the carbon emissions per vehicle produced by 5.6 % to

0.68 tons during the period under report.

In order to generate sufficient energy at its various pro-

duction plants, the BMW Group makes good use of its

own combined heat and power plants. The calculation

of energy efficiency within the BMW Group’s produc-

tion network has been adjusted to allow for increased

consumption caused by conversion due to the growing

use of CHP plants. The previous year’s figures have

been adjusted accordingly.

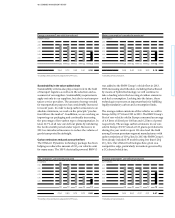

The volume of water required per vehicle produced also

fell to 2.18 m3 (– 1.8 %) in 2013. The amount of process

wastewater produced decreased by 7.8 % to 0.47 m3 per

vehicle produced. Measures implemented due to the

continual improvement process and good capacity

utili-

sation at our plants contributed towards improved

efficiency in the use of both energy and water. At the

Spartanburg plant in the USA in particular, water con-

sumption was lowered by the use of condensed water

gained from the cooling system.

The amount of non-recyclable production waste fell

significantly by 11.4 % to 5.73 kg per vehicle produced

in 2013. A strong contributing factor was the decrease

in non-recyclable waste by almost one-quarter (23.3 %)

at the Landshut plant.

Solvent emissions were reduced by an impressive 10.7 %

to 1.59 kg per vehicle produced during the period un-

der report, an achievement primarily due to the retrofit-

ting of the paint shop to include an exhaust air filtering

system at the Dadong2 plant in China.

Energy consumption – 31.0 %

Water consumption – 33.1 %

Process wastewater – 42.7 %

Non-recyclable waste – 69.7 %

Solvent emissions – 36.7 %

CO2 emissions – 35.2 %

1 Including BMW Brilliance joint venture.

2 Joint venture BMW Brilliance.