BMW 2013 Annual Report Download - page 33

Download and view the complete annual report

Please find page 33 of the 2013 BMW annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

33 COMBINED MANAGEMENT REPORT

More than one million vehicles produced in Germany

for third consecutive year

For the third year in a row, the Group manufactured

over one million vehicles at its German plants. The

pro-

duction start-up of the BMW 4 Series Coupé commenced

at the Group’s main plant in Munich. In future the plant

will be demonstrating its high degree of flexibility by

producing three different BMW 3 Series and BMW 4 Se-

ries models on one and the same production line. The

BMW 4 Series Coupé is the basic model for the BMW M4

Coupé, the production of which was prepared at the

Munich main plant over the course of 2013 and is

scheduled to start in 2014. During the year under report,

247,330 vehicles

were manufactured in Munich – more

than ever before.

Production of the BMW 4 Series Convertible began at

the Regensburg plant in 2013. In addition, the plant

celebrated the topping-out ceremony for its new supply

centre. The expansion of logistics structures is keeping

pace with the increased need for materials and plays

a key role in making the supply of parts for assembly

even more efficient. In parallel to these changes, further

progress was made to increase bodymaking capacity at

the plant, a process initiated in the previous year.

Pro-

duction capacity in the pressing plant was also expanded

with the commissioning into service of a new pressing

facility based on high-speed servo technology.

The BMW Group hired 700 new employees at its pro-

duction

plant in Leipzig in 2013, mainly to build up

expertise and create capacity for its BMW i models, but

also in the area of conventional carmaking. More over,

two new pressing lines employing high-speed servo

pressing technology were taken into service at the BMW

Leipzig plant with a view to increasing production

depth and flexibility in general. Series production of the

BMW 2 Series Coupé began in November. In parallel,

staff at the plant also made preparations for manufac-

turing

the BMW 2 Series Active Tourer from 2014 on-

wards, the first BMW model to be produced with front-

wheel drive.

In autumn the Dingolfing plant celebrated its 40th anni-

versary as a BMW production location. We were again

able to increase flexibility at the plant over the course of

the year. After a ten-year absence, the production start-

up of the 3 Series Gran Turisimo in spring heralded

the

return of a BMW 3 Series model to the Dingolfing

plant. Simultaneously, the plant began manufactur-

ing

the BMW M6 Gran Coupé. The number of vehicles

produced per day stood at the record level of some

1,500 units. Further good progress was made in ramping

up capacity at the plant, with construction work contin-

uing for a new bodymaking facility on a 25-hectare ex-

pansion area. One further major construction measure

undertaken at the Dingolfing plant was the ground,

breaking ceremony for the installation of a new high-

speed servo press.

At the components plant in Landshut in November, a

new die-casting foundry and a new core-moulding plant

were taken into operation. As the only BMW produc-

tion site to date that produces lightweight die-cast alloy

parts, it is now better able to serve the growing demand

for these components within the Group. The plant’s

production capacity now stands at 69,000 tons, which is

equivalent to some five million die-cast parts per year.

Global presence strengthened

Over 45 % of the BMW Group’s vehicles were

manufac-

tured abroad during the year under report. The

pro-

duction of the BMW 3 Series Sedan started at the Tiexi*

plant in the Chinese city of Shenyang at the beginning

of the year. Operations at this plant had only begun in

2012 and by September 2013, the 100,000th vehicle was

rolling off the assembly line. The BMW 5 Series long-

wheelbase Sedan is manufactured at the Dadong* plant

in China. In July, the 100,000th four-cylinder petrol

en-

gine made for the Chinese market came off the

produc-

tion line at the engine manufacturing plant in Shenyang.

At the same time, preparations got underway at the

site

for the construction of a further plant to supply en-

gines for local production.

In August 2013 the US plant in Spartanburg began manu-

facturing the new generation of the BMW X5. Since

2010, production capacity at the plant has practically

doubled. In the medium term, the plan is to increase ca-

pacity to accommodate up to 350,000 units per annum.

As from next year, as competence centre for the BMW X

models, the plant will also produce the BMW X4, the

latest addition to the X family. Furthermore, since this

year the American plant has been operating the world’s

largest connected fleet of hydrogen / fuel-cell-driven in-

dustrial logistics vehicles.

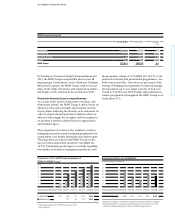

The BMW plant in Rosslyn, South Africa, has been run-

ning on a 24-hour basis in three shifts since 2012 and –

despite an eight-week strike in the car industry affecting

the entire country – manufactured a record volume of

65,646 units in 2013.

The BMW Group’s assembly plants in Egypt, India,

Indonesia, Malaysia, Russia and Thailand – whose

* Joint venture BMW Brilliance.