BMW 2010 Annual Report Download - page 34

Download and view the complete annual report

Please find page 34 of the 2010 BMW annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

32

12 GROUP MANAGEMENT REPORT

12 A Review of the Financial Year

14 General Economic Environment

18 Review of Operations

41 BMW Group – Capital Market

Activities

44 Disclosures relevant for takeovers

and explanatory comments

47 Financial Analysis

47 Internal Management System

49 Earnings Performance

51 Financial Position

53 Net Assets Position

55 Subsequent Events Report

55 Value Added Statement

57 Key Performance Figures

58 Comments on BMW AG

62 Internal Control System and

explanatory comments

63 Risk Management

70 Outlook

powers its fleet of forklift trucks by hydrogen. A solar

thermal plant installed at the BMW plant in Rosslyn

heats the water needed for the paint shop. At the Research

and Innovation Centre (FIZ) in Munich, the low tempera-

ture of the groundwater is used for air conditioning pur-

poses. Furthermore, at certain production sites the BMW

Group operates its own combined heat and power plants

that make particularly efficient use of resources.

Less water, less wastewater

Despite higher production volumes, the BMW Group has

reduced its water consumption by 370,000 m

3

compared

with the previous year. 2.31 m3 of water were consumed

per vehicle produced (–9.8%). The total amount of

process water used was reduced by 60,000 m

3

(–6.5%).

New technologies have contributed towards the improve-

ment,

such as “snow cleaning”, an innovative process

developed at the BMW Landshut plant, in which plastic

parts such as bumpers and wing mirrors are no longer

cleaned with water and detergents during production

butwith snow made from frozen carbon dioxide. The CO

2

is completely recovered and reused.

Waste and solvent emissions further reduced

The amount of non-recyclable production waste was de-

creased by a further 5.1% in 2010, as a result of which

only 10.09 kg of non-recyclable waste accumulated per

vehicle produced (2009: 10.63 kg). After successfully de-

creasing the amount by 28% the previous year, we have

meanwhile developed better ways of recycling waste

andusing materials more efficiently.

The BMW Group was able to reduce its solvent emissions

(VOC) by around 10% in 2010, bringing emissions per

vehicle produced down to 1.60 kg (2009: 1.77 kg). This

reduction was partly achieved through the use of low-

solvent and solvent-free rinsing and cleaning processes

in the painting pre-treatment process. Optimised colour-

change cycles in the paint shop further reduced the

number of cleaning processes required. Solvent

emis-

sions have been reduced by more than 30% since 2006,

so that we have already reached the target set for 2012.

Clean production in Shenyang

We are currently building a further plant in Shenyang,

China. Numerous ecological and social criteria were

taken into account when selecting the site of the new

plant. At the planning stage the location of the plant on

high ground was also chosen to compensate for any

future climatic changes and thus protect it from possible

flooding. A further criterion when deciding for the lo-

cation was the basic availability of renewable energy

sources. The paint shop will be the most sustainable fa-

cility in the entire BMW Group production network.

Eco-friendly transportation solutions

We also reduced the environmental impact of our freight

transportation in 2010 by optimising transportation net-

works. Regional shifts in sales volume resulted in changes

in the proportion of goods transported by each mode. At

0.5%, the percentage of goods transported by air freight

during the reporting year again remained very low (2009:

0.2%). Growth in China caused an increase in the per-

centage of sea freight to 79.9% (2009: 78.0%). The pro-

portion of goods transported by rail rose slightly to 6.3%

in 2010 (2009: 6.0%). Conversely, the percentage trans-

ported by road fell to 13.3% (2009: 15.8%).

Sales volume performance is also reflected in the distri-

bution of transportation methods for our new cars: in

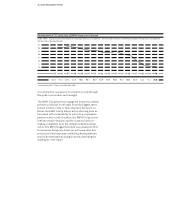

Energy consumed per vehicle produced

in MWh / vehicle

3.40

3.20

3.00

2.80

2.60

2.40

06

* 07 08 09 10

3.28 2.78 2.80 2.89 2.75

* Value extrapolated for 17 locations. Actual reporting covered ten locations.

CO2 emissions per vehicle produced

in t / vehicle

1.00

0.95

0.90

0.85

0.80

0.75

06

* 07 08 09 10

0.96 0.84 0.82 0.91 0.86

* Value extrapolated for 17 locations. Actual reporting covered ten locations.