BMW 2010 Annual Report Download - page 33

Download and view the complete annual report

Please find page 33 of the 2010 BMW annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.31 GROUP MANAGEMENT REPORT

Implementing sustainable management throughout

the Group

Following on from 2009, when the BMW Group’s sustain-

ability strategy underwent further comprehensive devel-

opment, a number of measures and assessment criteria,

derived from groupwide strategic plans, were established

in 2010 for the various areas of management responsibil-

ity. Driving these measures was the objective of remain-

ing the most sustainable car manufacturer in the world.

This was achieved again in 2010 and confirmed by an in-

dependent source: the BMW Group remains the auto-

mobile sector leader for the sixth consecutive year in the

Dow Jones Sustainability Index family.

Our primary objective is to instil the concept of sustaina-

bility throughout the entire value-added chain and its

underlying processes. We will therefore continue to de-

velop our innovative drive train technologies and imple-

ment concepts for sustainable mobility in metropolitan

areas. At production level, we will continue to cut down

on the volume of resources used, reduce the impact that

production processes have on the environment and en-

deavour to include ecological and social requirements

inthe supply chain. Furthermore, we wish to remain an

attractive employer for our staff in the future. As an inte-

gral part of society, we will continue to be involved in

finding solutions for social challenges.

Sustainable management based on a “balanced score-

card” is a corporate objective which is now integrated in

processes throughout the BMW Group. Every project is

now required to be assessed in terms of this objective.

This involves measuring the consumption of resources,

emissions and also the social and socio-political impacts.

Key elements in our sustainability management are the

continual and systematic analysis of external develop-

ments, ongoing dialogue with our stakeholders and the

consideration of both social and ecological aspects when

making decisions.

A sustainability structure has been established to en-

sure

that our sustainability efforts are continuously man-

aged and further developed. At the highest level in the

Group is the Sustainability Board which makes all deci-

sions of strategic relevance. All members of the Board of

Management are automatically members of this board.

The Sustainability Circle, consisting of representatives

from the various divisions and headed by the Group

Officer for Sustainability and Environmental Protection,

is responsible for implementing sustainability activities

across the Group.

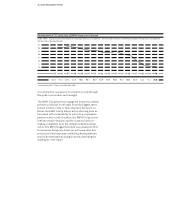

Clear targets for clean production

It is our intention to reduce the environmental impact of

production to the greatest extent possible. Items meas-

ured in this context include energy and water consump-

tion, process wastewater, solvent emissions and waste

fordisposal – expressed in terms of “waste per vehicle

produced”. We also measure carbon dioxide emissions

caused by the consumption of energy. The target is, by

2012, to reduce resource consumption and emissions

levels per vehicle produced by 30% compared with 2006.

Using an environmental efficiency figure as an indicator,

changes in resource consumption and emissions are

analysed across all items being measured. The environ-

mental efficiency figure for 2010 was improved by 6 per-

centage points during the period under report. The im-

provement since 2006 is 26%, surpassing the original

target of 20% set for 2010.

Energy consumption and emissions reduced

Total energy consumption in 2010 was reduced by

380,000 MWh and energy efficiency improved at the

same time. Energy consumed per vehicle produced in

2010 was 2.75 MWh (– 4.8%), in part helped by im-

proved capacity utilisation of equipment. As a result of

the lower amount of energy used in production, CO2

emissions were reduced by 74,700 tons. At 0.86 tons of

CO2 per vehicle produced, this was the equivalent of a

5.5% cut in emissions. Rigorous implementation of

savings measures is bringing us ever closer to our objec-

tive of improving energy efficiency by 30% between

2006 and 2012, in line with schedule.

Significant amounts of energy were saved through the

implementation of the “best practice” approach for inno-

vative production technologies. One example of this is

the new Integrated Paint Process (IPP) technology which

was initially developed at the Oxford plant and intro-

duced at the Spartanburg plant in 2010. The technology

ensures considerably lower environmental pollution and

higher productivity at the same time. After full conver-

sion, energy consumption in the paint shop will be re-

duced by 30%, CO2 emissions by 43% and solvent emis-

sions (VOC) by 7%. IPP has also reduced the processing

time per vehicle and will ultimately facilitate a produc-

tivity improvement of approximately 40%.

The aim is for each production site in the BMW Group

tobe powered by the most ecologically and economically

sustainable energy resource available. The US plant in

Spartanburg, for example, covers around 50% of its energy

needs using gas recovered from a nearby landfill site and