BMW 2010 Annual Report Download - page 202

Download and view the complete annual report

Please find page 202 of the 2010 BMW annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.-

1

1 -

2

2 -

3

3 -

4

4 -

5

5 -

6

6 -

7

7 -

8

8 -

9

9 -

10

10 -

11

11 -

12

12 -

13

13 -

14

14 -

15

15 -

16

16 -

17

17 -

18

18 -

19

19 -

20

20 -

21

21 -

22

22 -

23

23 -

24

24 -

25

25 -

26

26 -

27

27 -

28

28 -

29

29 -

30

30 -

31

31 -

32

32 -

33

33 -

34

34 -

35

35 -

36

36 -

37

37 -

38

38 -

39

39 -

40

40 -

41

41 -

42

42 -

43

43 -

44

44 -

45

45 -

46

46 -

47

47 -

48

48 -

49

49 -

50

50 -

51

51 -

52

52 -

53

53 -

54

54 -

55

55 -

56

56 -

57

57 -

58

58 -

59

59 -

60

60 -

61

61 -

62

62 -

63

63 -

64

64 -

65

65 -

66

66 -

67

67 -

68

68 -

69

69 -

70

70 -

71

71 -

72

72 -

73

73 -

74

74 -

75

75 -

76

76 -

77

77 -

78

78 -

79

79 -

80

80 -

81

81 -

82

82 -

83

83 -

84

84 -

85

85 -

86

86 -

87

87 -

88

88 -

89

89 -

90

90 -

91

91 -

92

92 -

93

93 -

94

94 -

95

95 -

96

96 -

97

97 -

98

98 -

99

99 -

100

100 -

101

101 -

102

102 -

103

103 -

104

104 -

105

105 -

106

106 -

107

107 -

108

108 -

109

109 -

110

110 -

111

111 -

112

112 -

113

113 -

114

114 -

115

115 -

116

116 -

117

117 -

118

118 -

119

119 -

120

120 -

121

121 -

122

122 -

123

123 -

124

124 -

125

125 -

126

126 -

127

127 -

128

128 -

129

129 -

130

130 -

131

131 -

132

132 -

133

133 -

134

134 -

135

135 -

136

136 -

137

137 -

138

138 -

139

139 -

140

140 -

141

141 -

142

142 -

143

143 -

144

144 -

145

145 -

146

146 -

147

147 -

148

148 -

149

149 -

150

150 -

151

151 -

152

152 -

153

153 -

154

154 -

155

155 -

156

156 -

157

157 -

158

158 -

159

159 -

160

160 -

161

161 -

162

162 -

163

163 -

164

164 -

165

165 -

166

166 -

167

167 -

168

168 -

169

169 -

170

170 -

171

171 -

172

172 -

173

173 -

174

174 -

175

175 -

176

176 -

177

177 -

178

178 -

179

179 -

180

180 -

181

181 -

182

182 -

183

183 -

184

184 -

185

185 -

186

186 -

187

187 -

188

188 -

189

189 -

190

190 -

191

191 -

192

192 -

193

193 -

194

194 -

195

195 -

196

196 -

197

197 -

198

198 -

199

199 -

200

200 -

201

201 -

202

202 -

203

203 -

204

204 -

205

205 -

206

206 -

207

207 -

208

208 -

209

209 -

210

210 -

211

211 -

212

212 -

213

213 -

214

214 -

215

215 -

216

216 -

217

217 -

218

218 -

219

219 -

220

220 -

221

221 -

222

222 -

223

223 -

224

224 -

225

225 -

226

226 -

227

227 -

228

228 -

229

229 -

230

230 -

231

231 -

232

232 -

233

233 -

234

234 -

235

235 -

236

236 -

237

237 -

238

238 -

239

239 -

240

240 -

241

241 -

242

242 -

243

243 -

244

244 -

245

245 -

246

246 -

247

247 -

248

248 -

249

249 -

250

250 -

251

251 -

252

252 -

253

253 -

254

254 -

255

255 -

256

256 -

257

257 -

258

258 -

259

259 -

260

260 -

261

261 -

262

262 -

263

263 -

264

264 -

265

265 -

266

266 -

267

267 -

268

268 -

269

269 -

270

270 -

271

271 -

272

272 -

273

273 -

274

274 -

275

275 -

276

276 -

277

277 -

278

278 -

279

279 -

280

280 -

281

281 -

282

282

|

|

FUTURE

Megacity Vehicle

20

It is true that the key to economical and ecological

volume production of CFRP lies in complete pene-

tration

of the value chain. It also explains why the

BMW Group is now able to exploit the potential of a

material many consider uniquely superior but too

di cult and costly for volume production.

CFRP is not only resistant to temperature fl uctua-

tions, acids and corrosion (and therefore much more

durable than metal), it is also 30 percent lighter than

aluminium and 50 percent lighter than steel. “CFRP

isthe lightest material that can be used in car-making

without compromising safety,” according to Nils

Borchers of the MCV development team. Crash tests

have proved that the Megacity Vehicle can withstand

a collision at least as well as conventional steel-

body

vehicles. This is primarily due to the LifeDrive

architecture, a revolutionary combination of a CFRP

passenger compartment and a chassis made of alu-

minium. While the aluminium frame known as the

drive module absorbs the collision energy in a crash,

the high-strength, carbon-fi bre reinforced life module

provides comprehensive protection for the Megacity

Vehicle’s occupants.

Since all of the drive units are located in the crash-

proof drive module, there is no need for a transmis-

sion tunnel, which typically relays engine power to

the rear wheels. This leaves the Megacity Vehicle much

more space for passengers – and gives the BMW

Group’s vehicle designers new scope for interior de-

sign. Last but not least, the brilliant two-module

de-

sign also has consequences for the vehicle’s production.

At the Leipzig plant where the Megacity Vehicle

will be assembled, the frame construction means that

complex conveyor technology is no longer needed.

This makes building a Megacity Vehicle less of an in-

vestment, much easier for employees to work with and

more fl exible than conventional production processes.

“Wecan ramp up MCV production quickly with re-

latively low outlay,” adds Martin Arlt of the

develop-

ment team. Its production will use 70 percent less water

and 50 percent less energy than the BMW Group’s

current plant average. Its total energy needs will

also be met completely from renewable sources.

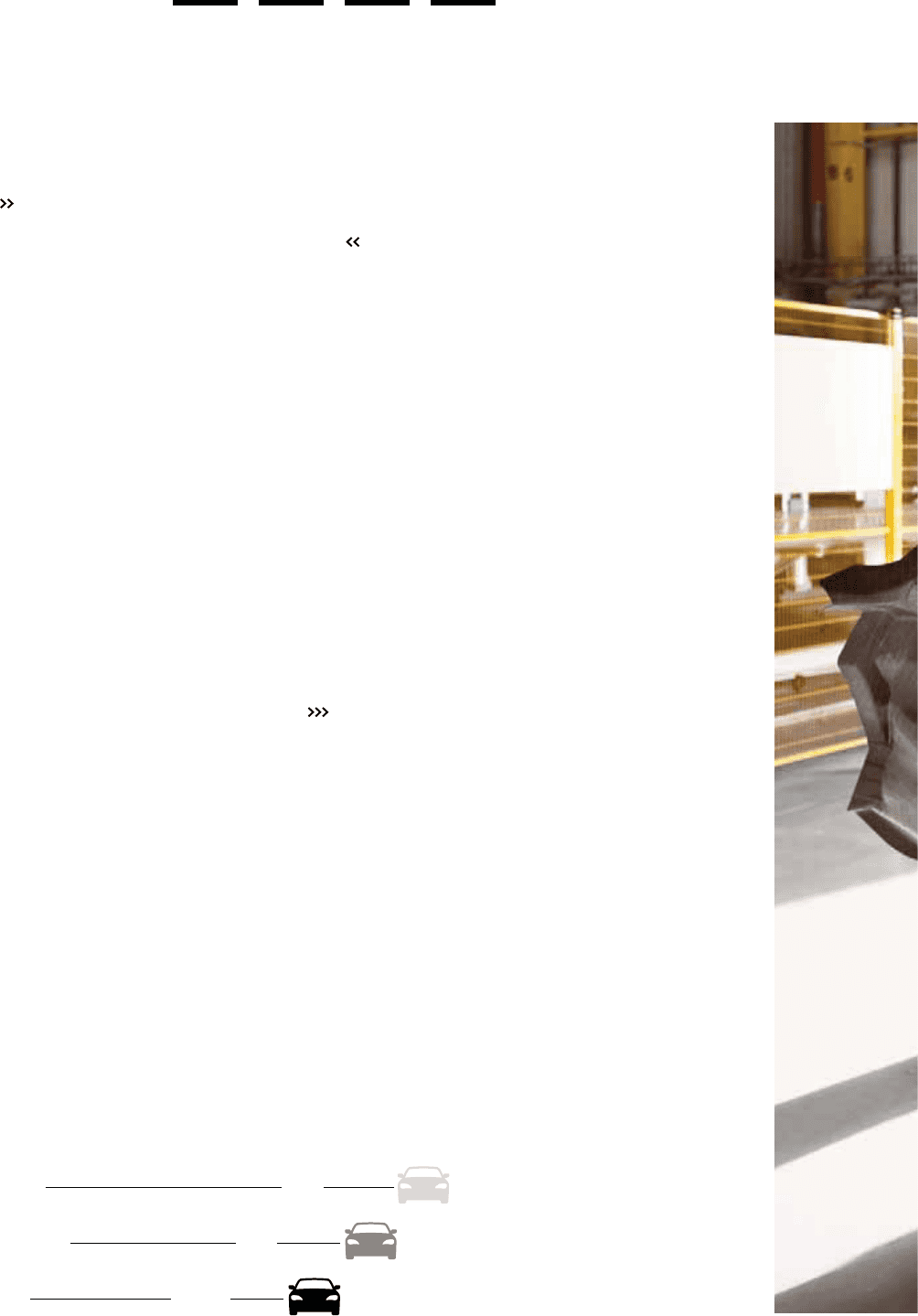

No other body material is

this light and stable.

Body weight in comparison

in percent

Aluminium 70

Steel

Carbon

100

50