BMW 2012 Annual Report Download - page 68

Download and view the complete annual report

Please find page 68 of the 2012 BMW annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

68

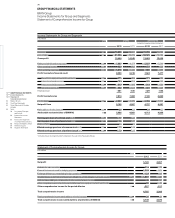

18 COMBINED GROUP AND COMPANY

MANAGEMENT REPORT

18 A Review of the Financial Year

21 General Economic Environment

24 Review of Operations

44 BMW Stock and Capital Market

47 Disclosures relevant for takeovers

and explanatory comments

50 Financial Analysis

50 Internal Management System

52 Earnings Performance

54 Financial Position

57 Net Assets Position

59 Subsequent Events Report

59 Value Added Statement

61 Key Performance Figures

62 Comments on BMW AG

65 Internal Control System and

explanatory comments

66 Risk Management

74 Outlook

model year 2025. Japan has also set ambitious targets

for reducing fuel consumption. Authorities in China are

currently discussing new, stricter regulations to tighten

up the existing individual vehicle fuel consumption rules

for the years 2013 to 2015.

The broader market introduction of alternative drive

systems means new challenges and additional investment

for the automotive industry. At the same time we also

see this as an opportunity to put our technological exper-

tise

and innovative strengths to use. Greater fuel econ-

omy and the reduction of emissions are fundamental

parameters that we automatically include when designing

new products.

In the short and medium term we will achieve greater fuel

economy by electrifying the drivetrain and developing

comprehensive hybrid systems. We are also working on

solutions for sustainable mobility in densely populated

areas. Large-scale field trials with the MINI E have

been

carried out in the UK, Germany, France, the USA,

China and Japan. A test fleet of BMW ActiveE electric

cars based on the BMW 1 Series Coupé has been on the

road since 2011. The extensive knowledge gained from

the trials will be used in the series development of the

BMW Group’s electric cars. The BMW i3 will come onto

the market at the end of 2013 as the first series-produced

electric car made by the BMW Group for the metro-

politan

regions

of the world.

Not only the safety of our customers, but that of all other

road users is an essential component of our product re-

sponsibility. The BMW Group analyses the entire pro-

cess chain from accident prevention to post-crash appli-

cations, such as the extended emergency call integrated

in Connected Drive, which is a unique innovation. In

order to minimise injury and damage caused by acci-

dents we are employing both active and passive safety

technologies. Active safety measures such as suspen-

sion regulation and driver assistance systems make an

essential contribution to the prevention of accidents.

Our enhanced technology in passive vehicle safety

has

also led to the latest BMW 3 Series and 5 Series

sedans achieving top marks in consumer tests world-

wide,

thereby setting new standards in their classes.

Moreover, the BMW Group is already researching

topics for which we are only likely to receive answers

in the longer term. These include, for instance, safety

questions that may only present themselves when a

far greater number of hybrid and electric cars are on

the

road.

Operational risks

Production

Production interruptions represent a major risk for the

BMW Group, due to the potential scale of their impact.

Apart from hazards posed by the elements (such as

fire

or flooding), power supply and IT breakdowns, pro-

duction interruptions can also be caused by logistical

problems (such as the failure of a supplier to deliver).

Precautionary measures are therefore incorporated in

production and logistics structures to make provision

for such eventualities, both in terms of likelihood of oc-

currence and loss impact. These measures include the

use of firewalls, sprinkler systems and auxiliary power

supplies.

The flexible nature of our production network and

working time models also generally help to reduce opera-

tional

risks. The assessment of both environmental

and

social risks when selecting new production sites is

also an important factor in minimising risk. Risks aris-

ing from business interruption and loss of produc-

tion due to acts of God are insured up to economically

reasonable levels with insurance companies that enjoy

a good credit standing.

Purchasing

The customary distribution of tasks between manufac-

turers and suppliers within the automotive sector

creates economic benefits, but also exposes contracting

parties to a certain degree of mutual dependence. As

part of a policy of preventative risk management imple-

mented within the purchasing function, suppliers are

assessed for technical competence on the one hand and

financial strength on the other, during both the develop-

ment and production phases of our vehicles. Suppliers’

risks at a local level also play an increasingly important

role in the context of decision-making. As part of our

catalogue of procedures, for instance, we also assess the

extent to which supplier sites are exposed to natural

hazards, such as floods or earthquakes, thus reducing

our exposure to parts supply risks.

Sustainability plays a crucial role in all of our purchas-

ing activities and is taken into consideration when

developing environmental, social and governance

standards. In this context, we manage sustainability

risks using a systematic three-stage risk management

approach, comprising risk filters, modularly designed