BMW 2012 Annual Report Download - page 28

Download and view the complete annual report

Please find page 28 of the 2012 BMW annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

28

18 COMBINED GROUP AND COMPANY

MANAGEMENT REPORT

18 A Review of the Financial Year

21 General Economic Environment

24 Review of Operations

24 Automotive segment

30 Motorcycles segment

31 Financial Services segment

33 Research and development

36 Purchasing

37 Sales and Marketing

39 Workforce

41 Sustainability

44 BMW Stock and Capital Market

47 Disclosures relevant for takeovers

and explanatory comments

50 Financial Analysis

65 Internal Control System and

explanatory comments

66 Risk Management

74 Outlook

Also in summer 2012, the five-millionth car rolled

off

the production line since manufacturing at the

Regensburg plant began in 1986. The plant has been

undergoing extensive expansion work since the

pre-

vious autumn. The pressing plant has been enlarged

and a second main production line set up for making

car bodies. We have also built an additional logistics

centre to handle increased material volumes. These

measures all contributed towards boosting the efficiency,

flexibility and start-up expertise at the Regensburg

plant, which is borne out by the numerous awards won

in 2012.

Electromobility production network

almost completed

Preparations for the series production of the BMW i

models represented an important focal point of activi-

ties at the Leipzig, Dingolfing and Landshut plants

during the year under report. These plants are being

built into a competence network for e-mobility, in which

the BMW i models will be produced in a multi-plant

system. Lightweight construction using carbon-fibre-

reinforced plastics (CFRP) plays a key role in the pro-

duction process.

The Leipzig plant is destined to play a major role in the

production and assembly of the BMW i models. The

building phase, as well as the enlargement of the body-

making and pressing plant, are proceeding according

to plan. In spring 2013, four wind turbines installed at

the plant’s premises will be put into operation to supply

the production of BMW i models with clean, renewable

energy. A total of 400 new employees have been recruited

to manufacture

the BMW i models and also take up con-

ventional production duties.

Series production of the

new five-door BMW 1 Series

also commenced with great

success in Leipzig.

In summer, the first assembly line for high-voltage bat-

teries designed for use in the new BMW i models went

into operation at the Dingolfing plant

, thus signalling

a further milestone on the

road to the series production

of BMW electric vehicles. The battery, the e-transmis-

sion and the aluminium

chassis for the BMW i3 will all

be built in Dingolfing.

Various components for the

BMW i8 will also be produced at the plant. Parallel to

preparations for the

BMW i vehicles, the Dingolfing

plant also mastered the successful start-ups of the BMW

6 Series Gran Coupé

and the BMW M6 Convertible.

In addition to all these activities, the BMW 6 Series as

well as various 5 and 7 Series models continue to be

manufactured at the plant.

A new production system for ultra-lightweight, high-

strength carbon parts went into operation at the Lands-

hut component plant in spring 2012. The carbon fibre

cores produced at the Wackersdorf plant are processed

in Landshut and Leipzig to form

CFRP

body parts

and

subsequently delivered to the CFRP body making unit

at the

BMW plant in Leipzig. The new, highly innova-

tive

CFRP production set-up in the two plants makes it

possible

for the first time to manufacture vehicle body

sections from carbon fibre parts in an automated, large-

scale production system.

The ceremony to celebrate the start of construction of

an expanded high-pressure die-casting foundry as

well

as a core-moulding plant also took place in

Lands hut in

April 2012. As the demand for die-cast lightweight alloy

parts is continually growing, production capacity will be

boosted from the current 58,000 tonnes

to 69,000 tonnes

per year in future. In addition, a new

resource-saving

smelting plant was commissioned in Landshut in the

autumn. The BMW Group is thereby

demonstrating how

economically viable production can be successfully

combined with ecological sustain ability. Conversion

from liquid to solid metal delivery is helping to achieve

a 10 % reduction in the total

volume of CO

2

emitted

from the aluminium smelter

through to completion of

the die-cast part.

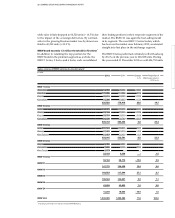

Global presence being strengthened

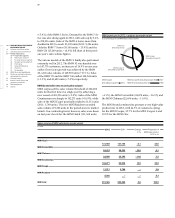

The BMW Group’s production network has meanwhile

grown to a total of 29 sites located in 14 countries. In

May the second carmaking plant of the BMW Brilliance

Automotive joint venture was opened at the Tiexi* site

in

Shenyang (China) and a local engine production plant

was also commissioned. The extended-wheelbase ver-

sions of both the BMW X1 and of the BMW 3 Series Se-

dan for the Chinese market are being built exclusively

in Tiexi*. The new plant sets standards in terms of tech-

nology and sustainability. Over 41,000 BMW vehicles

rolled off the production lines there in 2012. The ex-

tended-wheelbase version of the BMW 5 Series Sedan

is produced at the Dadong* plant in China.

The BMW Group’s global production presence has also

been reinforced by the enlargement of the plant at

Spartanburg in the USA. At the beginning of 2012 we

announced that the plant’s capacity would be extended

to up to 350,000 units by 2014. The BMW X models X3,

X5 and X6 as well as the X5 M and X6 M are currently

manufactured at the plant. During the year under report

the BMW Group decided that the BMW X4 will also be

* Joint venture BMW Brilliance