BMW 2012 Annual Report Download - page 249

Download and view the complete annual report

Please find page 249 of the 2012 BMW annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.-

1

1 -

2

2 -

3

3 -

4

4 -

5

5 -

6

6 -

7

7 -

8

8 -

9

9 -

10

10 -

11

11 -

12

12 -

13

13 -

14

14 -

15

15 -

16

16 -

17

17 -

18

18 -

19

19 -

20

20 -

21

21 -

22

22 -

23

23 -

24

24 -

25

25 -

26

26 -

27

27 -

28

28 -

29

29 -

30

30 -

31

31 -

32

32 -

33

33 -

34

34 -

35

35 -

36

36 -

37

37 -

38

38 -

39

39 -

40

40 -

41

41 -

42

42 -

43

43 -

44

44 -

45

45 -

46

46 -

47

47 -

48

48 -

49

49 -

50

50 -

51

51 -

52

52 -

53

53 -

54

54 -

55

55 -

56

56 -

57

57 -

58

58 -

59

59 -

60

60 -

61

61 -

62

62 -

63

63 -

64

64 -

65

65 -

66

66 -

67

67 -

68

68 -

69

69 -

70

70 -

71

71 -

72

72 -

73

73 -

74

74 -

75

75 -

76

76 -

77

77 -

78

78 -

79

79 -

80

80 -

81

81 -

82

82 -

83

83 -

84

84 -

85

85 -

86

86 -

87

87 -

88

88 -

89

89 -

90

90 -

91

91 -

92

92 -

93

93 -

94

94 -

95

95 -

96

96 -

97

97 -

98

98 -

99

99 -

100

100 -

101

101 -

102

102 -

103

103 -

104

104 -

105

105 -

106

106 -

107

107 -

108

108 -

109

109 -

110

110 -

111

111 -

112

112 -

113

113 -

114

114 -

115

115 -

116

116 -

117

117 -

118

118 -

119

119 -

120

120 -

121

121 -

122

122 -

123

123 -

124

124 -

125

125 -

126

126 -

127

127 -

128

128 -

129

129 -

130

130 -

131

131 -

132

132 -

133

133 -

134

134 -

135

135 -

136

136 -

137

137 -

138

138 -

139

139 -

140

140 -

141

141 -

142

142 -

143

143 -

144

144 -

145

145 -

146

146 -

147

147 -

148

148 -

149

149 -

150

150 -

151

151 -

152

152 -

153

153 -

154

154 -

155

155 -

156

156 -

157

157 -

158

158 -

159

159 -

160

160 -

161

161 -

162

162 -

163

163 -

164

164 -

165

165 -

166

166 -

167

167 -

168

168 -

169

169 -

170

170 -

171

171 -

172

172 -

173

173 -

174

174 -

175

175 -

176

176 -

177

177 -

178

178 -

179

179 -

180

180 -

181

181 -

182

182 -

183

183 -

184

184 -

185

185 -

186

186 -

187

187 -

188

188 -

189

189 -

190

190 -

191

191 -

192

192 -

193

193 -

194

194 -

195

195 -

196

196 -

197

197 -

198

198 -

199

199 -

200

200 -

201

201 -

202

202 -

203

203 -

204

204 -

205

205 -

206

206 -

207

207 -

208

208 -

209

209 -

210

210 -

211

211 -

212

212 -

213

213 -

214

214 -

215

215 -

216

216 -

217

217 -

218

218 -

219

219 -

220

220 -

221

221 -

222

222 -

223

223 -

224

224 -

225

225 -

226

226 -

227

227 -

228

228 -

229

229 -

230

230 -

231

231 -

232

232 -

233

233 -

234

234 -

235

235 -

236

236 -

237

237 -

238

238 -

239

239 -

240

240 -

241

241 -

242

242 -

243

243 -

244

244 -

245

245 -

246

246 -

247

247 -

248

248 -

249

249 -

250

250 -

251

251 -

252

252 -

253

253 -

254

254 -

255

255 -

256

256 -

257

257 -

258

258 -

259

259 -

260

260 -

261

261 -

262

262 -

263

263 -

264

264 -

265

265 -

266

266 -

267

267 -

268

268 -

269

269 -

270

270 -

271

271 -

272

272 -

273

273 -

274

274 -

275

275 -

276

276 -

277

277 -

278

278 -

279

279 -

280

280 -

281

281 -

282

282 -

283

283 -

284

284

|

|

51

A powerful crane peeps a warning as it hovers over

Sean Dempsey’s head; a press line with the dimensions of

a substantial apartment building towers in front of him,

while, at the other end of the enormous hall, an army of

pressing tools weighing several tons awaits. “Small” is

the last word anyone would use to describe the brand-new

press shop. And yet, as the

BBA

environmental expert

explains, many aspects here have been minimised: shorter

tool change times and ultra-high-speed stroke rhythms

ensure faster production cycles. Economical warehousing

takes up less space and therefore reduces the area to be

cooled, heated, cleaned and maintained.

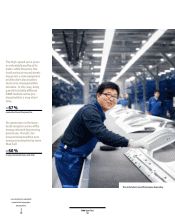

“This giant here,” says Dempsey, pointing at the huge press

line, “is something of a miracle when it comes to flexibility

and efficiency.” In fact, the so-called high-speed servo

press technology used at the plants in Leipzig, Regensburg

and Munich, and now also in Tiexi, is capable of up

to

17

strokes per minute. Compared with conventional

hydraulic presses, this not only reduces space requirements

and production time per unit (–

67

%), but also power

consumption per work step (–

60

%) and noise emissions

(–

13

%). In other words: the “titan of Tiexi” is much

faster, more efficient, more flexible and therefore more

economical than conventional presses – and quieter, too.

No less impressive are the performance figures for the

paint shop – the most resource-intensive section of any

car plant. Sean Dempsey explains how resources are

conserved and emissions prevented through use of an

integrated paint process developed at the Oxford plant,

so-called dry separation (used in the Leipzig,

Regensburg

and Spartanburg plants) and the RoDip dip-painting

process for corrosion protection. The environmental

expert is proud to point out that, all in all, Tiexi currently

boasts one of the most sustainable paint shop in the auto-

motive industry.

Environmental experts in the pressing tool store.

HIGH-SPEED

SERVO PRESS

“Higher speed and efficiency

ensure low energy

consumption and increased

productivity.”

Sean Dempsey on the high-speed servo press installed at the Tiexi plant

Every body part is

re-examined at the end

of the pressing process.