BMW 2012 Annual Report Download - page 42

Download and view the complete annual report

Please find page 42 of the 2012 BMW annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.-

1

1 -

2

2 -

3

3 -

4

4 -

5

5 -

6

6 -

7

7 -

8

8 -

9

9 -

10

10 -

11

11 -

12

12 -

13

13 -

14

14 -

15

15 -

16

16 -

17

17 -

18

18 -

19

19 -

20

20 -

21

21 -

22

22 -

23

23 -

24

24 -

25

25 -

26

26 -

27

27 -

28

28 -

29

29 -

30

30 -

31

31 -

32

32 -

33

33 -

34

34 -

35

35 -

36

36 -

37

37 -

38

38 -

39

39 -

40

40 -

41

41 -

42

42 -

43

43 -

44

44 -

45

45 -

46

46 -

47

47 -

48

48 -

49

49 -

50

50 -

51

51 -

52

52 -

53

53 -

54

54 -

55

55 -

56

56 -

57

57 -

58

58 -

59

59 -

60

60 -

61

61 -

62

62 -

63

63 -

64

64 -

65

65 -

66

66 -

67

67 -

68

68 -

69

69 -

70

70 -

71

71 -

72

72 -

73

73 -

74

74 -

75

75 -

76

76 -

77

77 -

78

78 -

79

79 -

80

80 -

81

81 -

82

82 -

83

83 -

84

84 -

85

85 -

86

86 -

87

87 -

88

88 -

89

89 -

90

90 -

91

91 -

92

92 -

93

93 -

94

94 -

95

95 -

96

96 -

97

97 -

98

98 -

99

99 -

100

100 -

101

101 -

102

102 -

103

103 -

104

104 -

105

105 -

106

106 -

107

107 -

108

108 -

109

109 -

110

110 -

111

111 -

112

112 -

113

113 -

114

114 -

115

115 -

116

116 -

117

117 -

118

118 -

119

119 -

120

120 -

121

121 -

122

122 -

123

123 -

124

124 -

125

125 -

126

126 -

127

127 -

128

128 -

129

129 -

130

130 -

131

131 -

132

132 -

133

133 -

134

134 -

135

135 -

136

136 -

137

137 -

138

138 -

139

139 -

140

140 -

141

141 -

142

142 -

143

143 -

144

144 -

145

145 -

146

146 -

147

147 -

148

148 -

149

149 -

150

150 -

151

151 -

152

152 -

153

153 -

154

154 -

155

155 -

156

156 -

157

157 -

158

158 -

159

159 -

160

160 -

161

161 -

162

162 -

163

163 -

164

164 -

165

165 -

166

166 -

167

167 -

168

168 -

169

169 -

170

170 -

171

171 -

172

172 -

173

173 -

174

174 -

175

175 -

176

176 -

177

177 -

178

178 -

179

179 -

180

180 -

181

181 -

182

182 -

183

183 -

184

184 -

185

185 -

186

186 -

187

187 -

188

188 -

189

189 -

190

190 -

191

191 -

192

192 -

193

193 -

194

194 -

195

195 -

196

196 -

197

197 -

198

198 -

199

199 -

200

200 -

201

201 -

202

202 -

203

203 -

204

204 -

205

205 -

206

206 -

207

207 -

208

208 -

209

209 -

210

210 -

211

211 -

212

212 -

213

213 -

214

214 -

215

215 -

216

216 -

217

217 -

218

218 -

219

219 -

220

220 -

221

221 -

222

222 -

223

223 -

224

224 -

225

225 -

226

226 -

227

227 -

228

228 -

229

229 -

230

230 -

231

231 -

232

232 -

233

233 -

234

234 -

235

235 -

236

236 -

237

237 -

238

238 -

239

239 -

240

240 -

241

241 -

242

242 -

243

243 -

244

244 -

245

245 -

246

246 -

247

247 -

248

248 -

249

249 -

250

250 -

251

251 -

252

252 -

253

253 -

254

254 -

255

255 -

256

256 -

257

257 -

258

258 -

259

259 -

260

260 -

261

261 -

262

262 -

263

263 -

264

264 -

265

265 -

266

266 -

267

267 -

268

268 -

269

269 -

270

270 -

271

271 -

272

272 -

273

273 -

274

274 -

275

275 -

276

276 -

277

277 -

278

278 -

279

279 -

280

280 -

281

281 -

282

282 -

283

283 -

284

284

|

|

42

18 COMBINED GROUP AND COMPANY

MANAGEMENT REPORT

18 A Review of the Financial Year

21 General Economic Environment

24 Review of Operations

24 Automotive segment

30 Motorcycles segment

31 Financial Services segment

33 Research and development

36 Purchasing

37 Sales and Marketing

39 Workforce

41 Sustainability

44 BMW Stock and Capital Market

47 Disclosures relevant for takeovers

and explanatory comments

50 Financial Analysis

65 Internal Control System and

explanatory comments

66 Risk Management

74 Outlook

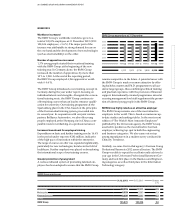

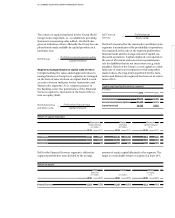

The high number of model start-ups, the increasing

number of models being launched and the greater verti-

cal range of manufacture, such as with CFRP, were the

main challenges in our endeavours to improve energy

efficiency. Expansion of our highly efficient and ecologi-

cally sustainable combined heat and power plants led to

higher consumption due to conversion factors. Despite

this fact we managed to reduce the energy consumed

per vehicle produced in 2012 to 2.44 MWh (– 0.8 %). This

improvement was achieved by means of a number of

measures such as the use of waste heat from the paint

shop at the Leipzig plant and the use of energy-efficient

motors for cooling the computer centre at our Oxford

plant. Greater energy efficiency and the use of electric-

ity produced from regenerative sources helped to re-

duce the CO2 emissions per vehicle produced by 4.2 %

to 0.68 tonnes during the period under report.

The volume of water required per vehicle produced also

fell to 2.10 m3 (– 0.9 %) in 2012. The amount of process

wastewater produced decreased by 11.1 % to 0.48 m3 per

vehicle produced. The conversion of the paint shop

in

Spartanburg to a water-free paint process and the re-

use of water in the paint shops at the Dingolfing and

Munich

plants were the main contributing factors to

this

reduction.

The volume of non-recyclable production waste was re-

duced by a further 23.5 % to 6.11 kg per vehicle pro-

duced in 2012. The primary reason for the improvement

was the conversion from waste disposal to recycling at

all plants in the UK.

Solvent emissions increased slightly by 1.8 % to 1.68 kg

per vehicle produced during the period under report,

largely due to increased production volumes in China.

New, eco-friendly painting processes will come on line

at the Tiexi* plant by the end of 2013. The paint shop

at the Dadong* plant is also scheduled for retrofitting

with a view to minimising solvent emissions in years to

come.

* Joint venture BMW Brilliance

Eco-friendly transportation solutions

The general increase in production volume combined

with regional shifts in demand had an impact on the

CO2 emissions per vehicle produced

in t / vehicle

0.90

0.85

0.80

0.75

0.70

0.65

08 09 10 11 12

0.82 0.91 0.86 0.71 0.68

Process wastewater per vehicle produced

in m3 / vehicle

0.70

0.60

0.50

0.40

0.30

0.20

08 09 10 11 12

0.64 0.62 0.58 0.54 0.48

Waste for disposal per vehicle produced

in kg / vehicle

17.5

15.0

12.5

10.0

7.5

5.0

08 09 10 11 12

14.84 10.63 10.09 7.99 6.11

Volatile organic compounds (VOC)

per vehicle produced

in kg / vehicle

2.50

2.25

2.00

1.75

1.50

08 09 10 11 12

1.96 1.77 1.60 1.65 1.68