Reebok 2007 Annual Report Download - page 71

Download and view the complete annual report

Please find page 71 of the 2007 Reebok annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

067

ANNUAL REPORT 2007 --- adidas Group

02

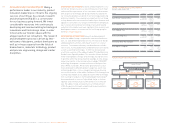

SYSTEM-BASED APPROACH TO MANAGE ENVIRONMENTAL

IMPACTS We have adopted a system-based approach to

managing environmental impacts in our own production facil-

ities and throughout our supply chain. Activities focus on

helping sup pliers establish sound environmental management

systems to best reduce their negative environmental impacts.

We develop guidelines and training programs for our suppliers

using the environmental performance of our own production

sites as examples of best practice. We have mandated the

implementation of environmental management systems at our

core suppliers to ensure continuous monitoring and improve-

ments. In our product creation process, we focus on improving

materials in our products and on tackling pollution in factories.

Our goal is to eliminate polluting materials and processes and

to increasingly utilize sustainable materials instead. To achieve

this goal we have several key initiatives in place such as con-

trolling and monitoring restricted substances and reducing

emissions of Volatile Organic Compounds (VOCs).

CONTROL AND MONITORING OF RESTRICTED SUBSTANCES

Restricted substances are those that cause harm or are sus-

pected to cause harm to human health or the environment.

Our suppliers are required to avoid using restricted sub-

stances. We have specifi ed clear standards that follow the

strictest local regulations and best practice standards for

consumer care and safety in the Group’s policy for monitoring

and control of hazardous substances. This policy is mandatory

for all business partners and is updated regularly based on

fi ndings in our ongoing dialog with scientifi c organizations.

Our standards cover the general requirements for eco-labels

and green seals (e. g. ÖKO-Tex Standard 100, Tox Proof TUV

Rhineland, etc.) for footwear, apparel and hardware products.

Both our own quality assurance laboratories and external

testing institutes are used to constantly monitor material

samples to ensure supplier compliance with these require-

ments. Materials that do not meet our standards and specifi -

cations are rejected.

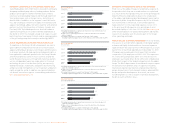

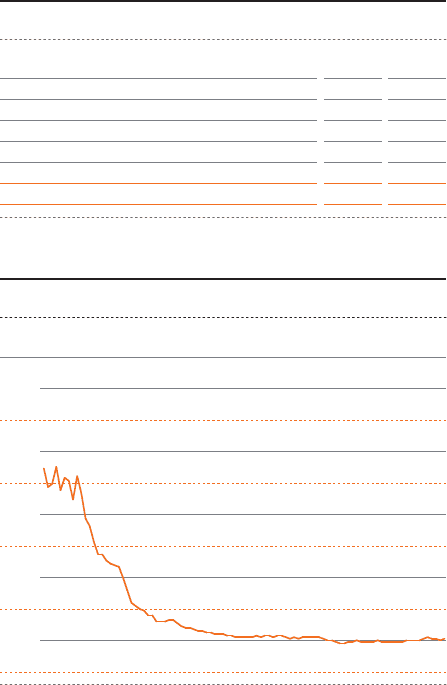

REDUCING VOC EMISSIONS Volatile Organic Compounds (VOCs),

which are typically found in solvents used in our manufacturing

process, can cause breathing diffi culties and other health

problems for production workers. Therefore, we are committed

to reducing VOC emissions in our suppliers’ footwear factories.

Our efforts focus on nearly all new adidas Group footwear

factories and refl ect the technical synergies of sharing infor-

mation, data and sources on production questions such as

water-based cement systems. At our core footwear suppliers

we measure the exposure and the records taken provide

evidence that workers are not being exposed to dangerous

levels of VOCs. Nonetheless, we remain committed to further

reducing emissions. In recent years, we have made signifi cant

progress. Our athletic footwear suppliers in Asia and Europe

have reduced VOC emissions from 140 grams per pair in 2000

to 20.3 grams per pair in 2007. Our target is an average VOC

emission of 20 grams / pair of shoes.

STRONG SUSTAINABILITY TRACK RECORD REFLECTED IN

INDEX MEMBERSHIPS We appreciate positive recognition

from international institutions and rating agencies, NGOs and

socially responsible investment analysts. They evaluate our

efforts through in-depth analysis of our social and environ-

mental program, including document review as well as inter-

views with employees and management. As a result, adidas AG

has been included in a variety of high-profi le sustainability

indexes. see Our Share, p. 036

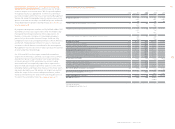

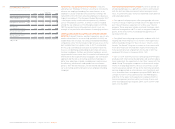

NUMBER OF FACTORY VISITS / AUDITS

Internal FLA

2003 1)

2004 1)

2005 1)

2006 2)

200

72

)

1

)

Includin

g

Salomon business se

g

ment

.

2

)

Includin

g

Reebok business se

g

ment.

906 13

954 12

916 14

1,101 43

1,007 15

7

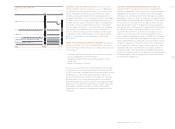

VOC CONSUMPTION 1)

i

n

g

rams per pair o

f

shoes produced

1999 2000 2001 2002 2003 2004 2005 2006 2007

160

1

2

0

80

40

0

1

)

At

y

ear-end.