Volvo 2009 Annual Report Download - page 57

Download and view the complete annual report

Please find page 57 of the 2009 Volvo annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

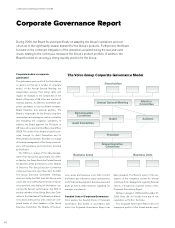

Emissions regulations for trucks and buses

EPA 2010

EPA 2007

0,16

0,14

0,12

0,10

0,08

0,06

0,04

0,02

0,00

Particles, g/kWh

NO

x, g/kWh

012345678

Euro II, 1996

Euro III, 2002

Euro IV, 2006

Euro V, 2009

EPA 2002

In September 2009, Euro V was implemented in

Europe and in January 2010, EPA 2010 was

implemented in North America. Euro V entails a

50% reduction of NOx emissions compared to Euro

IV. With the implementation of EPA 2010, emission

levels for particulates and NOx are very close to zero.

Euro VI, 2013

partner to customers, suppliers, other busi-

ness partners and entities in society as well as

a good employer.

The Volvo Group strives to take responsibil-

ity through such actions as imposing demands

on its suppliers. Since 2006, social issues

have been an integral part of supplier evalu-

ations and in 2008 a Group-wide project was

implemented for the purpose of further focus-

ing on this area.

Sustainability organization

Responsibility for the Volvo Group’s efforts

surrounding corporate social responsibility

issues is coordinated at the head ofce in line

with the respective operational responsibil-

ities. Work on core values is coordinated by a

Group Council.

Dialog with stakeholders

The Volvo Group strives to maintain straight-

forward, open communications with the world

at large and participates in the active exchange

of information with stakeholders on many dif-

ferent levels and in many different contexts.

The Group strives to consider different view-

points and evaluate these against our own

internal strategies for the purpose of achieving

sustainable development.

With the aim of being an active player in

social development and to nd business oppor-

tunities, it is essential that the Group is informed

about the surrounding world. It is with that in

mind that the Volvo Group analyzes social

trends and follows the development of new leg-

islation in regions in which the Group is active.

AB Volvo published its rst environmental

report in 1990. From 2002–2006 the Sustain-

ability Report was part of the Annual Report.

Since 2007, a separate Sustainability Report,

inspired by GRI (Global Reporting Initiative),

has been published. Detailed environmental

data is reported annually in a separate report.

Environmental

responsibility

High demands on production

and products

Environmental management is a cornerstone

of the Group’s efforts to promote long-term

sustainability. Volvo’s environmental work has

three distinct goals: to reduce the environmen-

tal impact of production, to reduce the impact

from the use of its products and to reduce the

impact from the Group’s own transports.

Guidance and control in the

environmental area

One of the most important elements for guid-

ance of environmental issues at the Volvo

Group is the common environmental policy.

The policy forms the basis for the Group’s

envir onmental management systems, strate-

gies, goals, audits and actions.

The environmental policy states that envir-

onmental efforts shall be marked by a holistic

view, continuous improvements, technical inno-

vation and efcient use of resources. The pol-

icy is, in turn, divided into strategies and goals

for the organization.

The rst environmental management sys-

tem was certied already in 1995. At the end

of 2009, 96% of the employees worked in

production units in accordance with certied

environmental management systems, primarily

ISO 14001:2004. Other aspects of the value

chain – such as product development and

marketing – also have management systems.

Most employees work in operations that have

quality management systems certied in

accordance with ISO 9001:2000.

The Group’s environmental goals are used

to monitor the entire organization, they are

geared towards both the Group’s own busi-

ness and the use of the products. The goals

are closely linked to business plans.

During the years 2004–2008, the Volvo

Group focused on energy reduction in the manu-

facturing operations. This resulted in a 43%

decrease of energy use per produced unit.

The goal for the next three years is a reduc-•

tion of a further 15%. Furthermore, a spe-

cic follow-up of idling losses will be carried

out; i.e. the energy usage during down time

in production.

The rst steps have been taken toward •

making the Group’s production plants CO2

neutral. Currently, the possibilities to make

more plants CO2 neutral are investigated.

A Group goal for more efcient use of pur-•

chased raw materials have been set. The

goal calls for an increased material ef-

ciency and an intensied follow-up of the

waste streams that come from prioritized

raw materials.

Product use goals include:

Achieving high fuel efciency and low emis-•

sions throughout the entire life cycle

Making comparisons with the best •

Consistent implementation of activities to •

become the industry leader

Generating environmental data for follow-•

up and communication during the develop-

ment of every new product

Implementing a strategy for future fuels •

Including alternative fuels and alternative •

drivetrains in the product portfolio.

The environmental program also includes part-

ners. Environmental requirements have been

used since 1996 as an integral component of

supplier evaluations and follow-up of various

purchasing organizations.

53