Volvo 2010 Annual Report Download - page 19

Download and view the complete annual report

Please find page 19 of the 2010 Volvo annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

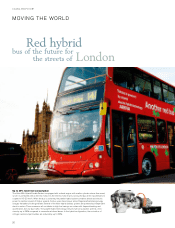

Volvo Buses

In the summer of 2010 serial production

started of Volvo’s hybrid buses, both

single deckers and double deckers.

Hybrid buses reduce fuel consumption

and emissions of CO2 by as much as

35%. The company has redeived orders

for some 200 hybrid buses in Europe

and has carried out positive tests at

operators in Brazil and Mexico.

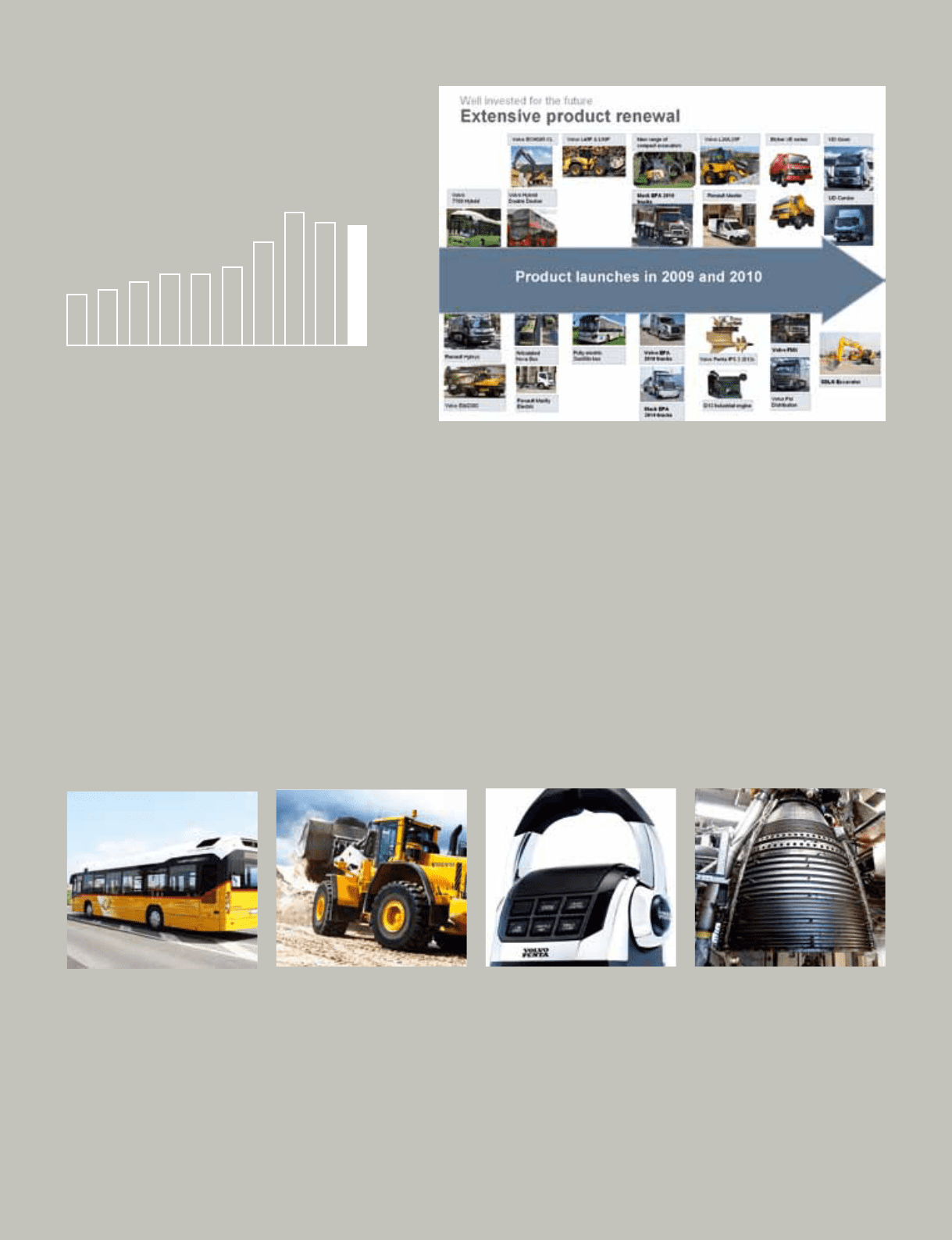

Volvo Construction Equipment

Volvo CE is highlighting its commitment

to improving fuel efficiency with a range

of solutions that encompasses engines,

hydraulic systems, operator behavior and

hybrid technology. The company is ram-

ping up its investments in new technol-

ogy to maintain its leadership in fuel

efficiency and thereby environmental

protection.

Volvo Penta

With new and specially designed con-

trols from Volvo Penta, boat drivers can

quickly choose between a number of

features, for example cruise control,

powertrim assistant and tow mode. The

electronics development makes it possi-

ble for Volvo Penta to offer its custom-

ers soft products of this kind. Also

among these is the appreciated joystick,

which makes maneuvering a boat easier

and safer.

Volvo Aero

The main challenge for the airline industry

is to reduce the engines’ fuel consump-

tion and thus also the emissions. Volvo

Aero’s lightweight technologies are

therefore in increasing demand from the

large, international engine manufacturers,

while the technologies also get new

applications in the aerospace industry

The drivelines are designed so they can be

adapted to a large number of applications in most

of the Group’s products. The diesel engines are

used in trucks, buses and construction equip-

ment, as well as in boats and industrial applica-

tions, such as generator units.

The strongest driver of the development of

drivelines is customer requirements and prefer-

ences as well as new legislation with stricter

emissions requirements. Products with reliability,

sustainability, good drivability, favorable fuel

economy and high environmental parameters

help boost customers’ productivity and profitability.

The environmental aspect is of great signifi-

Continued focus on product development

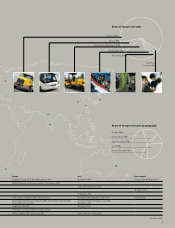

Research and development costs, SEK billion

04 05

030201 09 10

080706

7.6 7.66.85.95.4 13.2 13.014.311.18.4

cance in all product development. Alternative

drivelines and fuels, and the lower fuel consump-

tion when using traditional drivelines, provide for

twice the benefit – less impact on the environ-

ment and lower costs for customers. The Volvo

Group is a driving force in the areas of environ-

mental adaptation and energy efficiency. The

undertaking involves a gradual transition from

fossil fuels, such as oil and natural gas, to fuels

from renewable sources and to hybrids.

The Group continuously strengthens the

development of aftermarket products and ser-

vices with the aim of meeting customer needs

through the entire product life cycle.

Future direction

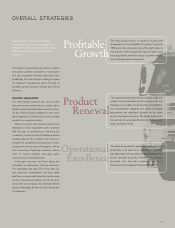

Within the strategic area of Product Renewal the

future direction is:

• Meet future emission standards with competitive

products – capitalize on converging technologies.

• Start production in India of medium-duty engine

platform developed by the Group.

• Develop new products adapted for growth markets.

• Further enhance the Group’s market-leading posi-

tion within diesel engines and automatic gear-

boxes.

• Commercialize the Group’s shared technology for

diesel-electric hybrids.

• Focus on fully utilizing common architecture and

shared technology.

15