HTC 2013 Annual Report Download - page 53

Download and view the complete annual report

Please find page 53 of the 2013 HTC annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

CORPORATE GOVERNANCE CORPORATE GOVERNANCE

102 103

All of the packaging materials for HTC products are compliable with the EC directive on packaging (EU

94/62/EC) the US requirement on packaging ( Model Toxics in Packaging Legislation of USA). All of the

printing ink used in HTC product packaging has low volatility or soy ink certified by the American Soybean

Association. These ensure that the environmental impact of packaging materials is minimized.

We try our best to use sustainable and reusable materials for packaging. If non-recycled paper must be

used in packaging, HTC requires the supplier to provide paper certified by the Forest Stewardship Council

(FSC) and Programme for the Endorsement of Forest Certification (PEFC). On the use of packaging, HTC

now uses only highly-recyclable packaging materials of these two types:

‧ Lightweight folded - paper packaging design:

70-80% from recycled paper pulp, this type of packaging is 100% recyclable once it is thrown away.

‧ Lightweight uni-body design: Made up of 65% sugar cane and 35% bamboo pulp, it is 100% recyclable

and 100% bio-degradable.

Apart from the above, all ink printed on HTC product packaging has low volatility and uses soy-based ink

from the U.S. Soybean Association. Every effort is made to minimize the environmental impact of HTC

product packaging.

We also set up a green supply chain management platform in 2006 that allows R&D engineers to look for

green products that meet increased international regulatory and customer requirements. Green materials

are introduced right from the design stage, greatly enhancing the reliability of the green product and trial

schedule. The management platform was upgraded in 2008 with an even more simple and convenient user

interface, along with better controls over hazardous substances.

4.1.3 Sustainable product

Carbon footprint verification

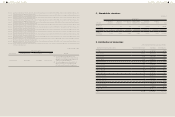

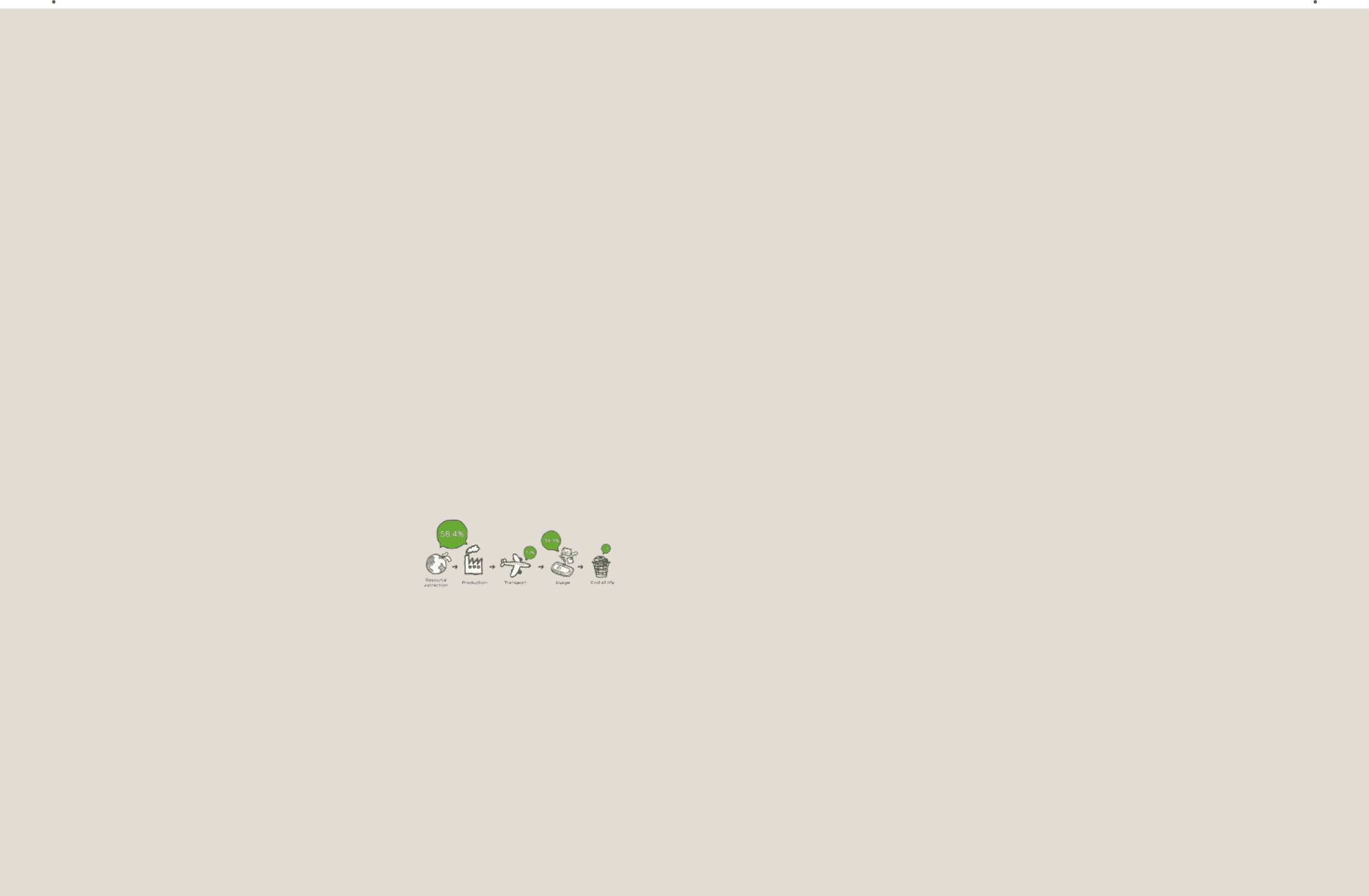

In 2013, the HTC One, our most representative product, went

through the product carbon footprint verification process by an

independent certification entity with the help of our suppliers.

The HTC One became the first smartphone built to international

specifications to complete the ISO/TS 14067:2013, PAS 2050:2011,

ISO 14040:2006 and ISO 14044:2006 product carbon footprint

and lifecycle assessments.

The product carbon footprint of HTC One was 40.5 kg CO2eq/functional unit.

4.2 Energy and climate change

HTC introduced the ISO 50001 energy management system in 2011 to learn about our internal energy

consumption, the relevant regulatory requirements and energy baseline to provide a reference for our

energy performance indicators as well as short-, mid- and long-term improvement goals. In 2009, HTC

introduced GHG emission inventory and disclosure for factories and offices throughout Taiwan.

GHG emissions in 2012 totaled 45,658.612 tonnes CO2e. We will expand the scope of our GHG emissions

inventory and external verification to subsidiaries we control in the future in order to provide comprehensive

statistics and monitoring of GHG emissions. The implementation of the ISO 50001 energy management

system and effective energy-saving measures will be used to increase overall energy efficiency, generating

better energy revenues and ecological benefits.

Apart from the regular annual GHG emission inventory and verification, HTC also reports our planning and

systems for carbon risk and carbon management on an annual basis in accordance with the requirements of

the Carbon Disclosure Project (CDP).

4.3 Water resource management

Climate change due to global warming has become increasingly evident making the storage and

distribution of water resources an important issue. At HTC, even though our production processes are not

water intensive we still strive to reduce water consumption during routine consumption. We also encourage

our factories to practice water resource management, recovery and reuse.

All of the water consumed during our operations comes from tap water. As all factory production lines

are dry processes that produce no industrial wastewater, water consumption is all from general office and

domestic use by employees.

The Taoyuan factory's water consumption in 2013 was 689,014 tonnes, with 220,430 tonnes of treated

domestic sewage. 160,985 tonnes of water were reclaimed, accounting for 73.03% of the treated wastewater.

The amount of reclaimed water has far exceeded the 60% target set for 2013. The amount of tap water used

was greatly reduced by using reclaimed water instead for watering factory landscaping and in toilets.

4.4 Waste reduction

HTC's main production process is the assembly of smartphones. The production process generates only

tiny amounts of emissions from soldering. No NOx or SOx emissions are generated. The production process

produces no hazardous waste. We have strengthened our waste management and disposal model in

accordance with the internal "Industrial Waste Disposal and Management Procedure". We also practice

thorough recycling and education. Proper disposal of waste ensures the cleanliness of the work environment

and reduces environmental impact.

On the management level, we adhered to government regulations in contracting licensed waste disposal

companies for proper waste disposal. Contractor trucks and disposal sites are also checked at irregular

intervals.

In the factory, we have also introduced a waste reduction strategy in addition to everyday waste

management. Waste classification and reduction education helps reduce waste at the source. Prioritization

is given to reuse as well to improve the recycling rate of resources. A total of 2,785,082 tonnes were

recycled in 2013.

4.5 Green factory

A Gold rating for Leadership in Energy & Environmental Design (LEED) from the U.S. Green Building

Council (USGBC) was set as the target during the planning stage of the Taoyuan factory and "HTC Taipei

Headquarters". LEED requirements were implemented during project planning, design and construction.

All engineering contractors were required to cooperate with and practice LEED requirements throughout

the construction process. Energy modeling found that the energy-saving design helped reduce power

consumption by 11.3% (Taoyuan) and 13.7% (Taipei) compared to the baseline scenario.

These two buildings will serve as the benchmark for new factories and offices built by HTC in the future

in order to provide employees and visitors with an environmentally friendly, energy-saving, water-saving,

comfortable and healthy space.

Proportion of carbon emissions throughout the HTC One

product lifecycle