BMW 2011 Annual Report Download - page 41

Download and view the complete annual report

Please find page 41 of the 2011 BMW annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

41 COMBINED GROUP AND COMPANY MANAGEMENT REPORT

produced". We also measure the level of CO2 emissions

resulting from energy consumption.

In the year under report we succeeded in reducing

both consumption of resources and emissions per

vehicle produced by an average of 8 percentage points.

In terms of resource efficiency, the average improve-

ment since 2006 has been 32 %.

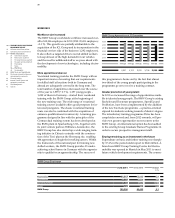

Energy efficiency further improved

Each production site throughout the BMW Group is

required to use the most ecologically and economically

sustainable energy resource available to it. In 2011,

CO

2

emissions per vehicle produced decreased by 17.4 %

to 0.71 tons. This was achieved primarily by increasing

the use of energy from renewable sources and improving

the energy mix. We were also able to further improve

energy efficiency levels during the

year under report.

The energy consumption per vehicle produced was re-

duced from 2.75 MWh to 2.46 MWh (– 10.5 %).

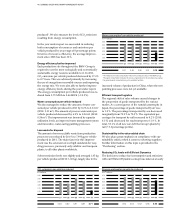

Water consumption per vehicle reduced

We also managed to reduce the amount of water con-

sumed per vehicle produced in 2011 by 8.2 % to 2.12 m³

(2010: 2.31 m³). The amount of process wastewater per

vehicle produced decreased by 6.9 % to 0.54 m³ (2010:

0.58 m³). The improvement was favoured by capacity

utilisation levels, an improved water management system

and innovative, water-saving painting processes.

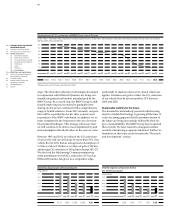

Less waste for disposal

The amount of non-recyclable waste from production

processes was reduced by 20.8 % to 7.99 kg per vehicle

produced in 2011. The main factor for this improve-

ment

was the extension of our high standards for recy-

cling processes, previously only valid for our European

plants, to all other plants worldwide.

Solvent emission levels rose slightly and averaged 1.65 kg

per vehicle produced (2010: 1.60 kg), largely due to the

increased volume of production in China, where the new

painting processes were not yet available.

Efficient transport logistics

The regional shift of sales volume caused changes in

the proportion of goods transported by the various

modes. As a consequence of the natural catastrophe in

Japan, the percentage of goods transported by air rose

to 1.0 %.

The percentage transported by sea decreased

marginally from 79.9 % to 78.9 %. The equivalent per-

centages for transport

by rail increased to 8.2 % (2010:

6.3 %) and decreased

for road transport to 11.9 %. In

total, 53.1 % of all new cars left the Group's plants by

rail (+ 3.6 percentage points).

Sustainability in the value-added chain

We also place great emphasis on compliance with sus-

tainability criteria when it comes to selecting suppliers.

Further information on this topic is provided in the

“Purchasing” section.

Reducing CO2 levels with Efficient Dynamics

The decision to reduce fuel consumption and emissions

with our Efficient Dynamics concept was taken at an early

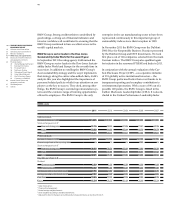

CO2 emissions per vehicle produced

in t / vehicle

0.95

0.90

0.85

0.80

0.75

0.70

07 08 09 10 11

0.84 0.82 0.91 0.86 0.71

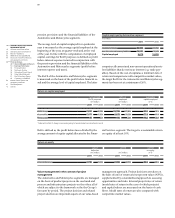

Water consumption* per vehicle produced

in m3 / vehicle

2.80

2.60

2.40

2.20

2.00

1.80

07 08 09 10 11

2.61 2.56 2.56 2.31 2.12

*

The indicators for water consumption refer to the production sites of the BMW Group.

The water consumption includes the process water input for the production as well as

the general water consumption e. g. for sanitation facilities.

Process wastewater per vehicle produced

in m3 / vehicle

0.70

0.60

0.50

0.40

0.30

0.20

07 08 09 10 11

0.64 0.64 0.62 0.58 0.54