BMW 2011 Annual Report Download - page 28

Download and view the complete annual report

Please find page 28 of the 2011 BMW annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

28

of integrating the production of the new BMW 3 Series

into existing manufacturing structures was commenced

in summer 2011, involving capital expenditure in the

region of € 300 million.

At the Wackersdorf plant we expanded the scope of

operations for cockpit production. From now on, cock-

pits will be produced there for both the BMW 3 Series

and the BMW 1 Series and supplied to our production

sites worldwide.

At the beginning of December, the BMW plant in Leip-

zig celebrated the one-millionth vehicle to leave its pro-

duction lines since operations commenced there. Al-

most 200,000 units were produced at the Leipzig plant

in 2011, more than ever before. The site's efficient and

flexible structures enabled it to rise to the challenge

of meeting high worldwide demand for the BMW X1 and

BMW 1 Series models. The BMW 1 Series M Coupé is

also being produced at the Leipzig plant, the first time

a BMW M model has been produced at this location.

Preparations also commenced in 2011 for the future

production of electric cars. In October 2011 a “topping

out” ceremony was held to celebrate the extending of

facilities built for producing future BMW i models. Pro-

duction here will be done on a CO2-neutral basis and

all energy used will come from renewable sources. Four

wind turbines set up at the site will generate sufficient

amounts of electricity to produce the BMW i models. In

the year under report we invested some € 183 million.

By the end of 2013 the BMW Group will have invested

€ 400 million in the project and created 800 jobs in the

process. Parallel to the above activities, a test fleet of

approximately 1,100 BMW ActiveE cars was produced

up to the beginning of 2012.

We are currently expanding the existing CFRP produc-

tion facilities at the BMW plant in Landshut. In future,

up to 100 employees will process carbon-fibre layers to

form CFRP components for the BMW i 3 and BMW i 8

models. The BMW Group boasts more than ten years of

expertise in working with this lightweight construction

material at the Landshut site. In order to extend our ex-

pertise in the area, the BMW Group and the Technische

Universität Munich are working together closely on a

related research and development project. In Septem-

ber 2011 we provided a carbon braiding machine to

fur-

ther develop braiding technology for CFRP components

for future automotive applications and to work on solu-

tions

for producing CFRP components on an industrial

scale. As part of the measures being taken to expand

capacities, the smelter at the Landshut lightweight

metal foundry will be redesigned and production

pro-

cesses modified to make them even more sustainable.

In future, residual metals will be recycled in the site’s

own smelter. This concept promises to cut costs and at

the same time reduce CO2 emissions along the entire

value-added chain by 10 %.

In 2011 the BMW Group’s largest engine factory in Steyr

established a new record by producing 1.2 million en-

gines, easily surpassing the high level of 1 million units

achieved in 2010. The Steyr plant again set standards

in the automotive sector in 2011, winning two top places

in the international “Engine of the Year Awards”.

The

BMW 6-cylinder petrol engine with TwinPower

Turbo

and the BMW 4-cylinder diesel engine with TwinPower

Turbo were both voted winners in their categories.

More than 190,000 MINIs were manufactured at the

Oxford plant in 2011. Production of the MINI Coupé

commenced in July, with the MINI Roadster following

in November.

We invested some € 100 million

in the

Oxford plant over the course of the year. Preparations

for the next MINI

generation were also set in motion.

The two-millionth MINI rolled off the production line

in Oxford in August

2011. The Hams Hall plant cele-

brated its tenth anni versary

in 2011. Production of

engines for the new

BMW 1 Series and 3 Series started

during the course of

the year. Al together, more than

430,000 engines were produced at Hams Hall in 2011,

a new record for the

site. In June

2011 we announced

plans to further expand the Hams Hall

plant to build

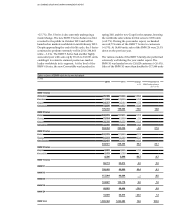

Vehicle production of the BMW Group by plant

in 2011

in 1,000 units

Dingolfing 343.2 Rosslyn 53.2

Spartanburg 276.1 Goodwood 3.7

Regensburg 260.0 Shenyang1 98.2

Leipzig 199.2 Graz (Magna Steyr)2 102.7

Oxford 191.5 Assembly plants 37.5

Munich 172.9

1 Joint venture BMW Brilliance

2 Contract production

Dingolfing

Munich

Regensburg

Oxford

Leipzig

Spartanburg

Rosslyn

Goodwood

Graz2

Assembly plants

Shenyang1

18 COMBINED GROUP AND COMPANY

MANAGEMENT REPORT

18 A Review of the Financial Year

20 General Economic Environment

24 Review of Operations

24 Automotive segment

29 Motorcycles segment

31 Financial Services segment

33 Research and development

36 Purchasing

37 Sales

38 Workforce

40 Sustainability

43 BMW Stock and Capital Market

46 Disclosures relevant for takeovers

and explanatory comments

49 Financial Analysis

66 Internal Control System and

explanatory comments

67 Risk Management

73 Outlook