BMW 2011 Annual Report Download - page 27

Download and view the complete annual report

Please find page 27 of the 2011 BMW annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

27 COMBINED GROUP AND COMPANY MANAGEMENT REPORT

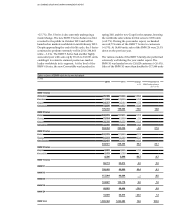

Sales volume of Rolls-Royce vehicles by model variant

in units

2011 2010 Change

in %

Rolls-Royce

Phantom (including Phantom Extended Wheelbase) 537 351 53.0

Coupé (including Drophead Coupé) 281 186 51.1

Ghost 2,720 2,174 25.1

Rolls-Royce total 3,538 2,711 30.5

Sales volume record for Rolls-Royce Motor Cars

Rolls-Royce Motor Cars also registered the best sales

volume figure in the 107 years of the marque’s history.

A

total of 3,538 units was sold in 2011 (+ 30.5 %) and

all of the Rolls-Royce models contributed to the brand’s

success. Luxury cars of the Phantom model series,

including the Coupé and the Drophead Coupé, were

handed over to 818 customers (+ 52.3 %). Sales of the

Ghost also rose sharply (+ 25.1 %) to 2,720 units. As a

result of this fine sales performance, Rolls-Royce leads

the segment for ultra-luxury vehicles.

Car production increased

The strong demand for our vehicles worldwide led to

production volumes being raised for all three brands

in 2011. In total, 1,738,160* BMW, MINI and Rolls-Royce

Motor Cars brand vehicles were manufactured during

the year under report (+ 17.3 %). The production of

BMW cars was increased by 16.4 % to 1,440,315* units,

while MINI production volume grew at an even faster

rate (294,120 units; + 22.0 %). A total of 3,725 vehicles

left the Rolls-Royce plant in Goodwood, England, in 2011

(+ 15.6 %).

* Including automobiles from the joint venture BMW Brilliance

Production capacities fully utilised

The production network again operated at full capacity

in 2011. Thanks to a high degree of flexibility, it was

able to react promptly to the economic upswing. Apart

from

achieving record production volumes, a total of

ten new series production start-ups were implemented,

including the new BMW 3 Series and 1 Series. Global

growth is being met by increasing capacities in various

regions, including the USA, China and India, thus

enabling the BMW Group to strengthen its international

presence. At the same time, we are also investing

some

€ 2 billion in our German production sites in 2011

and 2012.

At the BMW plant in Munich, the ramp-up of

produc-

tion for the new BMW 3 Series was at the forefront of

activities in 2011, culminating in its world debut in

Munich on 14 October. Apart from the great number

of invited guests, the event was attended by some

5,000 BMW Group employees. The official production

start-up of the new BMW 3 Series, now in its sixth

generation, took place on 28 October. In the field of

engine production, the major emphasis was placed

on

the production start of the new BMW 4-cylinder

petrol

engine in 2011; some € 205 million was invested in

these start-ups at the BMW plant in Munich in 2011.

Production of the BMW 5 Series, 6 Series and 7 Series

at the BMW plant in Dingolfing proceeded at record

levels in 2011 in order to meet the strong demand for

our vehicles worldwide. In April 2011 the eight-

mil-

lionth BMW left the plant’s production lines since 1973.

Well over 340,000 vehicles were produced at the site in

the year under report, more than in any other single

year. Production of the new BMW 6 Series Coupé began

in July and was followed in autumn by the BMW M5,

now in its fifth generation. January 2012 marked the

production launch of the BMW ActiveHybrid 5, the first

fully hybrid BMW Sedan. Over the course of 2011 we in-

vested some €270 million to rejuvenate the site’s manu-

facturing technologies and prepare for the production

of new models and components. As a result of these

various developments, which will also include the making

of engine and drive com ponents for electric models

under the BMW i sub-brand, the Dingolfing site is set

to be one of the main pillars of the BMW Group’s future

Electromobility Production Network.

The BMW plant in Regensburg saw the production launch

of the new BMW 1 Series on 1 July 2011, the culmination

of some € 300 million of investment during the period

since 2009. One of the measures taken has been to

inte-

grate the world’s first dry separation method in the

painting process. Now, instead of being filtered out in

water, excess

paint particles are collected in the form of

recyclable stone powder. This new process helps to

reduce both water and energy consumption. The

process