Audi 2012 Annual Report Download - page 43

Download and view the complete annual report

Please find page 43 of the 2012 Audi annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

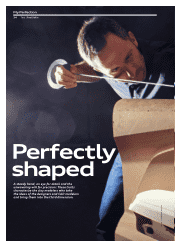

My Perfection

fenders, for example, are a challenge.

The concave and convex surfaces

that meet there must be shaped in

such a way that it looks homogeneous

yet at the same time dynamic.”

“Sometimes you get stuck. You

model dierent variants, but none

of them really fit,” says Müller when

describing the eort of his daily work.

“In these cases, I like to come in on

a Saturday because I am alone here

and can tinker in peace. I usually also

find a solution, and these are special

moments for me.”

These are surpassed only by the

feeling that occurs when a model

receives an enthusiastic response at

a presentation following weeks of

hard work. “By then at the latest you

know that the sweat and overtime

were worth it,” says Müller, who has

often experienced this. Until then,

however, the clay modelers work

behind the scenes, and generally on

multiple pieces at the same time. Four,

five or more clay models are created

and refined step-by-step on the way

to a new Audi. In the end, the final

model is shaped inside and out so that

visually it is almost indistinguishable

from a real vehicle. Windows, radiator

grille, instruments, even remote-

controlled headlights perfect the

illusion. The modelers report that at

one presentation this has resulted in

someone trying to open a door and

ending up with the handle in their

hand. In a way this is also a testament

to the perfection down to the finest

detail – a characteristic feature of all

Audi models.

There is an average of two years

between the initial idea and the

decision whether a clay model will

become a production vehicle. “That

sounds like a long time,” says Sommer

in deep concentration as he draws a

spatula through the modeling clay at

the center console. “But what applies

to fine wine also applies to our work:

It needs time to mature.” «

Finishing touches to the front end:

Volker Ried (left) and Joachim Müller

refine every detail to the very end.

It doesn’t harden like normal clay,

but rather can be heated again and

again using an industrial dryer and

remodeled. “This enables us to make

corrections quickly and easily at any

time,” says Müller. The creation of

the model is a process of constant

changes in which the modelers and

designers work in close collaboration

from beginning to end. “We are in

constant dialogue,” adds Müller.

“Tomorrow we may find a solution

that is better than one we like today.”

The exterior model is covered with

between 500 kilograms and one metric

ton of industrial clay. Four modelers

spend two to three days working on it

before the model takes on its initial,

rough shape – despite the fact that

they only model one side of the vehicle.

This is then covered in measuring

points and scanned millimeter by

millimeter via the photogrammetry

process. The data are used to program

a milling machine that creates a

complete mirror image of the shape

on the unprocessed side of the model

overnight.

Sommer says that modeling is the

best part of his job, “partly because

it comes with a certain amount of

creative freedom. We can contribute

our own ideas, even if it is just a matter

of tiny details. But you take especially

great pride in these. You can then stand

in front of the finished vehicle and

say there is a little bit of me in there.”

Exterior specialist Ried is also familiar

with this triumph. “It is a special

moment, particularly when an area was

complicated and you spent a lot of

time experimenting with it. The front

Visit to the Audi Model

Studio: Experience the clay

modelers at work.

P H O T O S | M A N F R E D J A R I S C H ; J I M R A K E T E

40