Volvo 2008 Annual Report Download - page 64

Download and view the complete annual report

Please find page 64 of the 2008 Volvo annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

Focus on integration

Integration work of both the Chinese wheel

loader manufcturer Lingong and the road

machinery business line is going according to

plan. The road machinery product portfolio has

been fully Volvo branded.

Investments

The ongoing investment that began in 2007 to

eliminate capacity bottlenecks in the com-

ponent production facility in Eskilstuna, Sweden

started to take effect in 2008.

During the year it was also announced that

the production of centre-mounted backhoe

loaders would move from Poland to Mexico.

This will speed delivery times to the North and

Latin American markets, where the product is

particularly popular, and decrease the impact

of currency fl uctuations.

Furthermore, there were investments an-

nounced in new paint shops in the com pany’s

articulated hauler plant in Braås, Sweden and

in its cab factory in Hallsberg, Sweden. These

will lead to a reduced environmental impact

and quality improvements.

The product portfolio

Volvo CE continues to evlove as a total solu-

tion provider and to develop its segmentation

approach to customer needs. In line with the

Group’s strategy to increase to grow within

soft products, Volvo CE continues to expand

its soft products offering, including remote

machine monitoring systems and uptime serv-

ices.

The rental business has expanded with 15

new rental stores in North America, Europe

and Other markets.

Products launched in 2008 included:

• L220F Hybrid wheel loader prototype

• L45F and L50F mid-sized wheel loaders

• EC60C and EW210C mid-sized excavators

• L180F HL high lift wheel loader

• Feller bunchers for the forestry segment.

Fuel-effi cient technology

At the ConExpo exhibition held in Las Vegas in

March 2008, Volvo CE showcased the indus-

try’s fi rst prototype hybrid wheel loader, the

Volvo L220F Hybrid. The diesel-electric hybrid

drive system offers improved performance

characteristics and reduces emissions and fuel

consumption. To meet the environmental

requirements and emission legislations of the

future Volvo CE is developing a range of Tier IV

engines and has the technology in place to

meet expected bio-fuel environmental legisla-

tion.

New President

Olof Persson was named Volvo Construction

Equipment’s new President in September. He

has an extensive international experience from

ABB, Bombardier and Daimler Chrysler and

was most recently President of Volvo Aero.

Volvo Penta

– continues to capture

market share

Volvo Penta offers complete drive systems

and service for leisure boats, workboats and

industrial applications such as diesel-powered

Continued investments in a new, global •

logistics system.

New European dealer structure •

implemented.

Expanded customer offering of soft •

products.

Secure favorable profi tability also in •

weaker market conditions.

Secure successful implementation of •

new, global logistics structure.

Continue to expand industrial engine •

business to improve balance between

business segments.

Focus on delivery capacity to ensure •

favorable product supply in the market.

Intensify work to ensure a positive •

product cost development.

Establishment of a new global dealer •

network structure.

Continued introduction of soft products •

and service programs.

Outcome 2008 Ambitions 2009Ambitions 2008

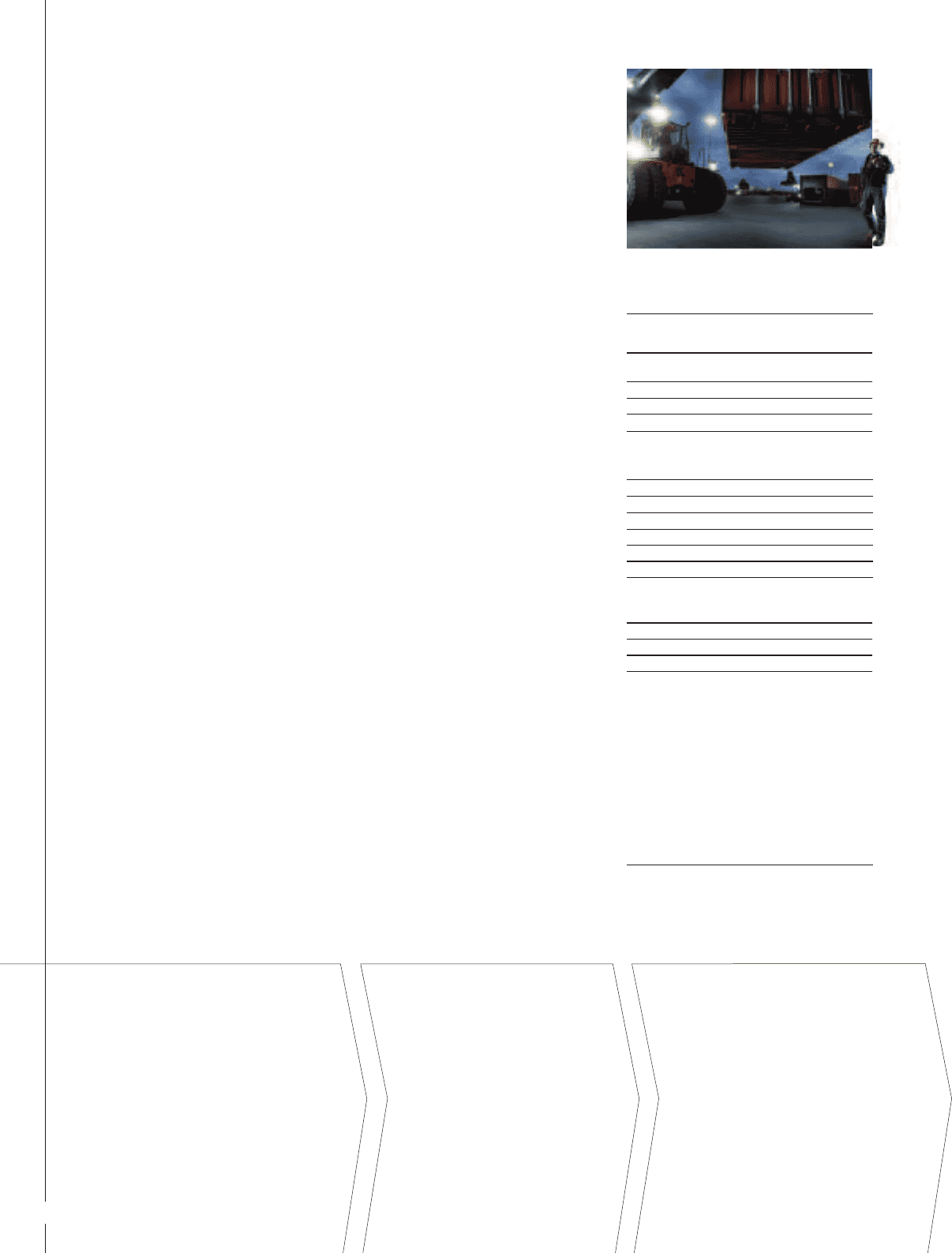

VOLVO PENTA

Net sales by market

Volvo Penta, SEK M 2007 2008

Europe 6,798 6,554

North America 2,674 1,947

South America 274 364

Asia 1,624 2,082

Other markets 349 486

Total 11,719 11,433

Engine volumes

Volvo Penta, No. of units 2007 2008

Marine engines 67,333 51,270

Industrial engines 23,728 26,061

Total 91,061 77,331

Key ratios

Volvo Penta 2007 2008

Net sales as percentage

of Volvo Group sales 44

Net sales, SEK bn 11.7 11.4

Operating income, SEK M 1,173 928

Operating margin, % 10.0 8.1

Kalmar Industries is a world-leading manufacturer of

different machines for materials handling and one of

Volvo Penta’s largest industrial engine customers.

Business areas 2008

60