Xcel Energy 2009 Annual Report Download - page 74

Download and view the complete annual report

Please find page 74 of the 2009 Xcel Energy annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.Environmental Matters

Environmental costs include payments for nuclear plant decommissioning, storage and ultimate disposal of spent

nuclear fuel, disposal of hazardous materials and waste, remediation of contaminated sites and monitoring of discharges

to the environment. A trend of greater environmental awareness and increasingly stringent regulation has caused, and

may continue to cause, higher operating expenses and capital expenditures for environmental compliance.

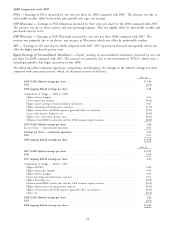

In addition to nuclear decommissioning and spent nuclear fuel disposal expenses, costs charged to operating expenses

for environmental monitoring and disposal of hazardous materials and waste were approximately:

• $225 million in 2009;

• $213 million in 2008; and

• $173 million in 2007.

Xcel Energy expects to expense an average of approximately $256 million per year from 2010 through 2014 for similar

costs. However, the precise timing and amount of environmental costs, including those for site remediation and disposal

of hazardous materials, are currently unknown. Additionally, the extent to which environmental costs will be included

in and recovered through rates is not certain.

Capital expenditures for environmental improvements at regulated facilities were approximately:

• $89 million in 2009;

• $230 million in 2008; and

• $439 million in 2007.

Xcel Energy expects to incur approximately $79 million in capital expenditures for compliance with environmental

regulations and environmental improvements in 2010, and approximately $530 million of related expenditures from

2011 through 2014. Included in these amounts are expenditures to reduce emissions of generating plants in Minnesota

and Colorado.

See Note 17 to the consolidated financial statements for further discussion of Xcel Energy’s environmental

contingencies.

Generating facilities throughout the Xcel Energy territory currently are subject to mercury reduction requirements only

at the state level. In Minnesota mercury emissions from A. S. King and Sherco generating facilities are regulated by the

Minnesota Mercury Legislation, and in Colorado, eight units are subject to a mercury emissions rule passed by the

Colorado Air Quality Control Commission (AQCC).

In November 2008, the MPUC approved and ordered the implementation of the Sherco Unit 3 and A. S. King

mercury emission reduction plans. A sorbent injection control system was installed at Sherco Unit 3 in December 2009,

with installation at A. S. King scheduled for December 2010. In November 2009, the MPUC authorized

NSP-Minnesota to collect approximately $3.5 million from customers through a mercury rider in 2010.

In December 2009, NSP-Minnesota filed the plans for mercury control at Sherco Units 1 and 2 with the MPUC and

the MPCA. Assuming these plans are approved, NSP-Minnesota expects to file for recovery of the costs to implement

these plans through the mercury cost recovery rider.

The EPA has required states to develop implementation plans to comply with BART, which included identification of

facilities that will have to reduce SO2, NOx and particulate matter emissions under BART and then set BART

emissions limits for those facilities. The Colorado AQCC promulgated BART regulations requiring certain major

stationary sources to evaluate and install, operate and maintain BART to make reasonable progress toward meeting the

national visibility goal. PSCo estimates that implementation of BART alternatives will cost approximately $254 million

in capital costs, which includes approximately $113 million in environmental upgrades for the existing Comanche

Station Units 1 and 2 project, which are included in the capital budget. PSCo expects the cost of any required capital

investment will be recoverable from customers. Emissions controls are expected to be installed between 2012 and 2014.

Colorado’s state implementation plan has been submitted to EPA for approval. In January 2009, the CAPCD initiated a

joint stakeholder process to evaluate what types of additional NOx controls may be necessary to meet reasonable

progress goals for Colorado’s Class I areas, the new ozone standard, and Rocky Mountain National Park nitrogen

deposition reduction goals. The CAPCD has indicated that it expects to have a final plan for additional point-source

NOx controls by the end of 2010.

64