Reebok 2011 Annual Report Download - page 95

Download and view the complete annual report

Please find page 95 of the 2011 Reebok annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

adidas Group

2011 Annual Report

GROUP MANAGEMENT REPORT – OUR GROUP

91

2011

02.5 Global Operations

by almost 40%. The function will continue to look for opportunities

to semi-automate process steps in production where possible, while

supporting this effort with the endorsement of lean manufacturing

principles throughout its supply base.

The Profitability Management department within Global Operations

assumes a central role in realising cost competitiveness by driving

our strategic costing efforts and optimising our buying strategies.

Throughout 2011, the function has been developing a model of profit

and productivity incentives that serves as a basis for productivity

improvement discussions with our supply base. As part of this

initiative, data and documenting processes were analysed across

the adidas and Reebok brands to make differences in cost policies

transparent in order to align them longer-term.

Providing industry-leading availability

Building on the solid platform that has been established to ensure

product availability, Global Operations is further shortening our order-

to-delivery lead times. This will be accomplished by establishing and

offering a set of tailored and sophisticated replenishment models to our

customers and own-retail activities via improvements in our planning

systems and processes. The overarching goal of these initiatives is to

delay decisions on customer-specific order adjustments to the latest

possible point in time for increased flexibility in how we plan, produce,

deliver and stock product.

As part of this priority, Global Operations is building five new supporting

system solutions that use SAP as a basis to standardise, automate,

bundle and execute market processes and system functionalities. The

roll-out of these systems and processes is a prerequisite to enable

enhanced value-added services (e.g. labelling, price tags and RFID

tags) at our factories and distribution centres. These are also critical

for our flexible make-to-stock service which aims to improve product

availability and inventory utilisation by planning and building inventory

buffers at different locations further up the supply chain.

Other capabilities that the function is building include an increased

level of transparency on lead times in our supply chain. This will

allow for more pro-active and accurate instructions on delivery times,

planning and purchasing, resulting in a reduction of workload and

increased customer satisfaction. Another important aspect will be the

introduction of the capability to transfer inventory between locations in

a more automated manner.

Enabling later ordering

Enabling later ordering is a cross-functional priority in Global

Operations aimed at allowing our customers and own-retail network

to order our products closer to the time of sale, facilitating buying

decisions that are based on better market knowledge.

This priority focuses on reducing production lead times on footwear

and, ultimately, apparel to 60 days. In 2011, we succeeded in bringing

70% of Reebok footwear articles onto this lead time. Since the majority

of adidas footwear is already on 60 days, the change will allow us to

align sales processes across the brands and improve efficiencies. For

apparel, Global Operations has now developed a 60-day lead time

concept, which will be rolled out in three phases starting in the second

half of 2013.

Further order-to-delivery lead time reductions will be achieved

through a greater regional source base, which will enable us to

manufacture closer to our key markets to deliver and replenish

products faster. Today, Global Operations already sources significant

portions of apparel for the US market regionally. Business cases for

additional countries and specific business categories are currently

being reviewed.

On Group level, Global Operations is also a key contributor to the

company’s Integrated Business Planning (IBP) project

SEE INTERNAL

GROUP MANAGEMENT SYSTEM, P. 114

. IBP forms part of the Group’s Driving Route

2015 programme and aims at establishing a coherent end-to-end

demand and supply planning process across finance, marketing and

operations.

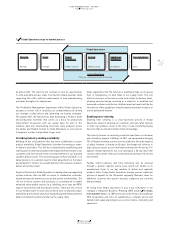

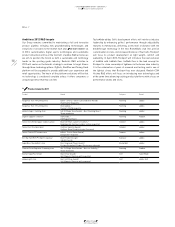

02 Global Operations in go-to-market process

Global Operations

Marketing

Briefing

Design

Concept

Product

Development

Product creation

Sourcing

Manufacturing

Supply Chain

Management

Distribution

Sales Subsidiaries

Sales

Centre of Excellence

Processes and infrastructure of the future