Reebok 2011 Annual Report Download - page 94

Download and view the complete annual report

Please find page 94 of the 2011 Reebok annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

adidas Group

2011 Annual Report

GROUP MANAGEMENT REPORT – OUR GROUP

90

2011

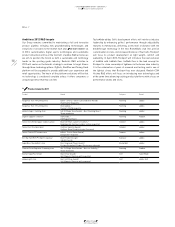

02.5 Global Operations

Global Operations

Global Operations manages the development, production planning, sourcing and distribution of the

majority of our products. The function continually strives to increase efficiency throughout the Group’s

supply chain and ensure the highest standards in product quality and delivery performance for our

customers and our own-retail and eCommerce activities at competitive costs.

02.5

The vision of Global Operations is to be closest to every consumer. The

function strives to provide the right product to consumers – in the right

size, colour and style, in the right place, at the right time, across the

entire range of the Group’s channels and brands.

Global Operations has a strong track record for establishing state-of-

the-art infrastructure, processes and systems. The function has been

successfully consolidating and improving legacy structures, reducing

complexity and cost for the Group. By taking strong ownership for

quality, cost and availability, we have proven that we are able to

respond to the fast-changing requirements of both our consumers

and customers.

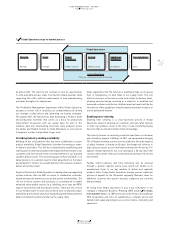

To support our Route 2015 strategic business plan, Global Operations

focuses on five strategic priorities driven by several key initiatives

TABLE 01

. The implementation of these initiatives is well underway,

with three already completed in 2011 (adidas NEO label, Fast and Lean

Creation and FlexPLM). By continuing to deliver on these initiatives,

Global Operations will not only enable the Group to achieve its goals,

it will also ensure our supply chain remains a competitive advantage

in making us the partner of choice for our consumers and customers

alike.

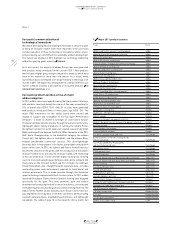

Ensuring cost competitiveness

Global Operations focuses on further optimising product creation

through an efficient material and colour selection process. This,

coupled with increased automation in manufacturing, will enhance

productivity, shorten lead times and improve overall quality. These

improvements are expected to enhance profitability for the Group

and ensure we provide our consumers with the best value proposition

possible.

In 2011, a joint effort between Global Operations and Global Brands

yielded initial results on consolidating material and colour numbers,

which will already start to deliver benefits in spring/summer 2013.

In the area of automation and manufacturing efficiency, pilot lines

were established in several factories for most categories. Parts

produced per hour for these lines have improved in some instances

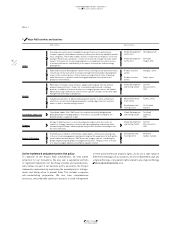

01 Five strategic priorities for Global Operations

Strategic priorities Specific goals Implemented through strategic initiatives

Ensuring cost competitiveness Reduce product and supply chain

costs

– Optimise product creation through efficient material and colour

selection

– Increase the level of automation in the manufacturing processes

– Pool supply chain activities at a central level

Providing industry-leading availability

Enhance existing logistics services

to create a flexible and cost-efficient

supply chain

– Offer tailored replenishment models to customers, using improved

planning processes and systems

– Develop flexible planning and production models

– Plan and build inventory buffers at different locations in the supply chain

Enabling later ordering Allow customers to order products

later, i.e. closer to the time of sale

– Reduce production lead times for footwear and apparel to 60 days

– Establish a regional source base

Supporting the Group’s growth projects Support the company’s Route 2015

priorities

– Build fast-fashion creation, sourcing and supply chain management

capabilities

– Further roll-out of processes and systems

– Offer short lead time production models

Modernising the Group’s infrastructure

Build the required operational

backbone to support the Group’s

growth plans

– Consolidate legacy systems and distribution structures

– Build state-of-the-art systems, processes and distribution facilities