LensCrafters 2009 Annual Report Download - page 16

Download and view the complete annual report

Please find page 16 of the 2009 LensCrafters annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

DESIGN AND PRODUCT

DEVELOPMENT

Emphasis on product design and the continuous development of new styles is key to success. Each year,

Luxottica adds approximately 2,300 new styles to its eyewear collections.

Design is at the focal point where vision, technology and creativity converge. Ever in search of innovation

and originality, the designers "see" eyewear as art, as objects to put on display. Driven by this "vision", they

survey the market and its famous names but draw above all on their own imagination and inexhaustible

creativity.

Luxottica’s in-house designers oversee the entire concept phase of the creative process, culminating in the

creation of the model. At this point, the prototype makers transform designs into one-off pieces, crafted

by hand with meticulous precision.

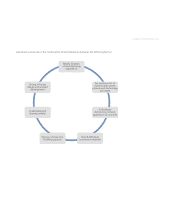

Once the prototypes or style concepts are developed in the initial phase of design, they are passed on to

the product department, which uses 3D software to analyze the steps necessary to bring the prototype to

mass production.

Three main manufacturing technologies are involved: metal, acetate slabs and plastic (injection molding).

At this point in the cycle, the tooling shop puts together equipment needed to make the components for

the new model. The fi rst specimens obtained are assembled and undergo a series of tests required by

internal quality control procedures.

The next steps are production and quality certifi cation of sales samples of the new models. These samples

are subjected to a sequence of tests to ascertain the quality of what has been engineered so far.

The fi nal step is the production of an initial signifi cant batch using defi nitive tooling certifi ed by an external

standards organization, in a pilot facility accurately representing the Luxottica plant chosen to mass pro-

duce the new model to meet the needs of production planning.

Speed and effectiveness in coordinating the various phases enhance overall effi ciency. Communication

and interaction between people and departments is key to achieving a constant stream of new solutions

and a creative process that generates unique products.

> 14