Audi 2010 Annual Report Download - page 55

Download and view the complete annual report

Please find page 55 of the 2010 Audi annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

53

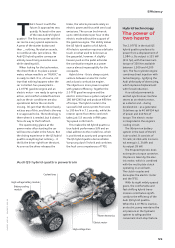

High-end material CFRP

The direction

has to be right

Carbon fi ber-reinforced plastics Carbon fi ber-reinforced plastics

(CFRP) are an excellent material (CFRP) are an excellent material

for not only the aerospace for not only the aerospace

and aviation industries, but also and aviation industries, but also

for making cars. They have long for making cars. They have long

demonstrated their strengths demonstrated their strengths

in motorsports. Depending in motorsports. Depending

on their confi guration, they on their confi guration, they

achieve outstanding tensile achieve outstanding tensile

strengths of 500 to 1,350 strengths of 500 to 1,350

Newtons per square millimeter, Newtons per square millimeter,

absorb energy very well, are absorb energy very well, are

extremely lightweight and off er extremely lightweight and off er

the greatest possible design the greatest possible design

freedom.freedom.

A single carbon fi ber is only A single carbon fi ber is only

fi ve to eight micrometers fi ve to eight micrometers

thick, or roughly one tenth the thick, or roughly one tenth the

thickness of a human hair. As a thickness of a human hair. As a

rule, 1,000 to 50,000 of them rule, 1,000 to 50,000 of them

are combined to form rovings are combined to form rovings

(strands), which are the base (strands), which are the base

material for the fabric. The layer material for the fabric. The layer

structure is what determines structure is what determines

the material properties: Because the material properties: Because

CFRP materials are only high-CFRP materials are only high-

strength in the direction of the strength in the direction of the

fi bers, the individual layers are fi bers, the individual layers are

laid down in diff erent directions. laid down in diff erent directions.

They are embedded in a matrix, They are embedded in a matrix,

usually epoxy resin. When the usually epoxy resin. When the

resin cures, the part is fi nished. resin cures, the part is fi nished.

The parts are still largely The parts are still largely

built by hand today. Further built by hand today. Further

developments in production developments in production

technology are required before technology are required before

CFRP parts can be used in large-CFRP parts can be used in large-

volume production.volume production.

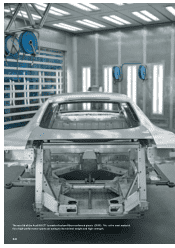

Whereas the degree of automation in

A8 production is nearly identical to that

with a conventional steel sheet body,

production of the exclusive R8 high-

performance sports car has more of a

handcrafted character.

With the R8, the front end, the

central fl oor and the rear end are

assembled separately from one

another. After the assemblies are joined

to form the substructure, the pillars

and the large metal panels – primarily

the roof, the side walls, the doors and

the cover panels – are added. “The

key factor is the joining technology,”

explains Elend. “We mostly use joining

techniques developed and patented by

Audi for production.”

The perfect interplay throughout

the entire process chain – from

development and planning, the

building of the machines, fi xtures and

tools, to the press shop, body shop and

the paint shop, all the way through to

assembly – all takes place according to

Audi’s exacting quality standards.

A fully automatic measuring system

checks the dimensional accuracy of each

body down to a tenth of a millimeter.

The scanner works without contact and

uses its 95 laser sensors to check 220

points within fi ve seconds.

Further extending the lead in struc-

tural design and fabrication is also

what drives Elend to new innovations.

After all, carmaking is once again facing

a system change, and this change

is bringing with it new tasks for the

lightweight design specialists. “Future

drive concepts set new requirements

for the body and add additional weight

to the car,” says the new Head of

the Audi Lightweight Design Center.

“This presents us with an entirely new

set of challenges regarding proper

implementation for the materials

involved.”

Audi will use lightweight design con-

cepts to off set the signifi cant added

weight for electrifi ed drive systems.

This also includes the use of innovative

materials. It was for this reason that the

Company invested in a new technical

center for fi ber-reinforced composite

materials back in 2009.

In particular, these include carbon

fi ber-reinforced plastics (CFRP), which

Audi will use in an intelligent material

mix with aluminum and steel, for

example, but also with ultra-light

magnesium. The pioneering eff orts in

the fi eld of aluminum construction will

help to transfer the know-how to other

technologies and materials. “We know

what it means to take a new material

to production maturity,” says Board

Member Michael Dick, “and we will also

demonstrate this with CFRPs.”

Lightweight design is even visible

in the R8 Coupé*. Its CFRP sideblades

in structured honeycomb look are an

unmistakable design element. In the

open version, the R8 Spyder*, the

percentage of CFRP parts was increased

even further. The side panels and the

complex top compartment cover are

made of the lightweight carbon fi ber.

“The CFRP hatch yields weight savings

of roughly 20 percent compared

to aluminum,” says Elend. “This

component has such a complex shape

that it would not even be possible with

metallic materials,” adds Timm,

his predecessor under whose leadership

the structure of the R8 was developed.

The new materials therefore off er not

only signifi cant weight advantages, they

also off er new design possibilities. The

R8 GT* shows just what potential the

composite materials harbor. The rear

hatch of the limited production model

is made of CFRP for a weight advantage

of 6.6 kilograms. The bucket seats,

which feature a chassis made of glass

fi ber-reinforced plastic (GFRP), save

31.5 kilograms.

In the future, the challenge will lie

in the ability to also produce ultra-

light materials economically in large

volumes. So the lightweight design

specialists from Neckarsulm will not be

short on work – and certainly won’t be

running out of ideas.

THOMAS AMMANN

Visible high-tech: CFRP sideblade

of the Audi R8 GT.

A system change in carmaking

is looming as a result of electric

mobility.

Visit the Audi Lightweight

Design Center: www.audi.com/

ar2010/lightweight