Audi 2010 Annual Report Download - page 166

Download and view the complete annual report

Please find page 166 of the 2010 Audi annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.-

1

1 -

2

2 -

3

3 -

4

4 -

5

5 -

6

6 -

7

7 -

8

8 -

9

9 -

10

10 -

11

11 -

12

12 -

13

13 -

14

14 -

15

15 -

16

16 -

17

17 -

18

18 -

19

19 -

20

20 -

21

21 -

22

22 -

23

23 -

24

24 -

25

25 -

26

26 -

27

27 -

28

28 -

29

29 -

30

30 -

31

31 -

32

32 -

33

33 -

34

34 -

35

35 -

36

36 -

37

37 -

38

38 -

39

39 -

40

40 -

41

41 -

42

42 -

43

43 -

44

44 -

45

45 -

46

46 -

47

47 -

48

48 -

49

49 -

50

50 -

51

51 -

52

52 -

53

53 -

54

54 -

55

55 -

56

56 -

57

57 -

58

58 -

59

59 -

60

60 -

61

61 -

62

62 -

63

63 -

64

64 -

65

65 -

66

66 -

67

67 -

68

68 -

69

69 -

70

70 -

71

71 -

72

72 -

73

73 -

74

74 -

75

75 -

76

76 -

77

77 -

78

78 -

79

79 -

80

80 -

81

81 -

82

82 -

83

83 -

84

84 -

85

85 -

86

86 -

87

87 -

88

88 -

89

89 -

90

90 -

91

91 -

92

92 -

93

93 -

94

94 -

95

95 -

96

96 -

97

97 -

98

98 -

99

99 -

100

100 -

101

101 -

102

102 -

103

103 -

104

104 -

105

105 -

106

106 -

107

107 -

108

108 -

109

109 -

110

110 -

111

111 -

112

112 -

113

113 -

114

114 -

115

115 -

116

116 -

117

117 -

118

118 -

119

119 -

120

120 -

121

121 -

122

122 -

123

123 -

124

124 -

125

125 -

126

126 -

127

127 -

128

128 -

129

129 -

130

130 -

131

131 -

132

132 -

133

133 -

134

134 -

135

135 -

136

136 -

137

137 -

138

138 -

139

139 -

140

140 -

141

141 -

142

142 -

143

143 -

144

144 -

145

145 -

146

146 -

147

147 -

148

148 -

149

149 -

150

150 -

151

151 -

152

152 -

153

153 -

154

154 -

155

155 -

156

156 -

157

157 -

158

158 -

159

159 -

160

160 -

161

161 -

162

162 -

163

163 -

164

164 -

165

165 -

166

166 -

167

167 -

168

168 -

169

169 -

170

170 -

171

171 -

172

172 -

173

173 -

174

174 -

175

175 -

176

176 -

177

177 -

178

178 -

179

179 -

180

180 -

181

181 -

182

182 -

183

183 -

184

184 -

185

185 -

186

186 -

187

187 -

188

188 -

189

189 -

190

190 -

191

191 -

192

192 -

193

193 -

194

194 -

195

195 -

196

196 -

197

197 -

198

198 -

199

199 -

200

200 -

201

201 -

202

202 -

203

203 -

204

204 -

205

205 -

206

206 -

207

207 -

208

208 -

209

209 -

210

210 -

211

211 -

212

212 -

213

213 -

214

214 -

215

215 -

216

216 -

217

217 -

218

218 -

219

219 -

220

220 -

221

221 -

222

222 -

223

223 -

224

224 -

225

225 -

226

226 -

227

227 -

228

228 -

229

229 -

230

230 -

231

231 -

232

232 -

233

233 -

234

234 -

235

235 -

236

236 -

237

237 -

238

238 -

239

239 -

240

240 -

241

241 -

242

242 -

243

243 -

244

244 -

245

245 -

246

246 -

247

247 -

248

248 -

249

249 -

250

250 -

251

251 -

252

252 -

253

253 -

254

254 -

255

255 -

256

256 -

257

257 -

258

258 -

259

259 -

260

260 -

261

261 -

262

262 -

263

263

|

|

164

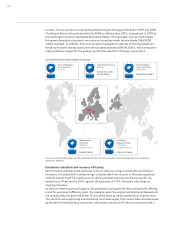

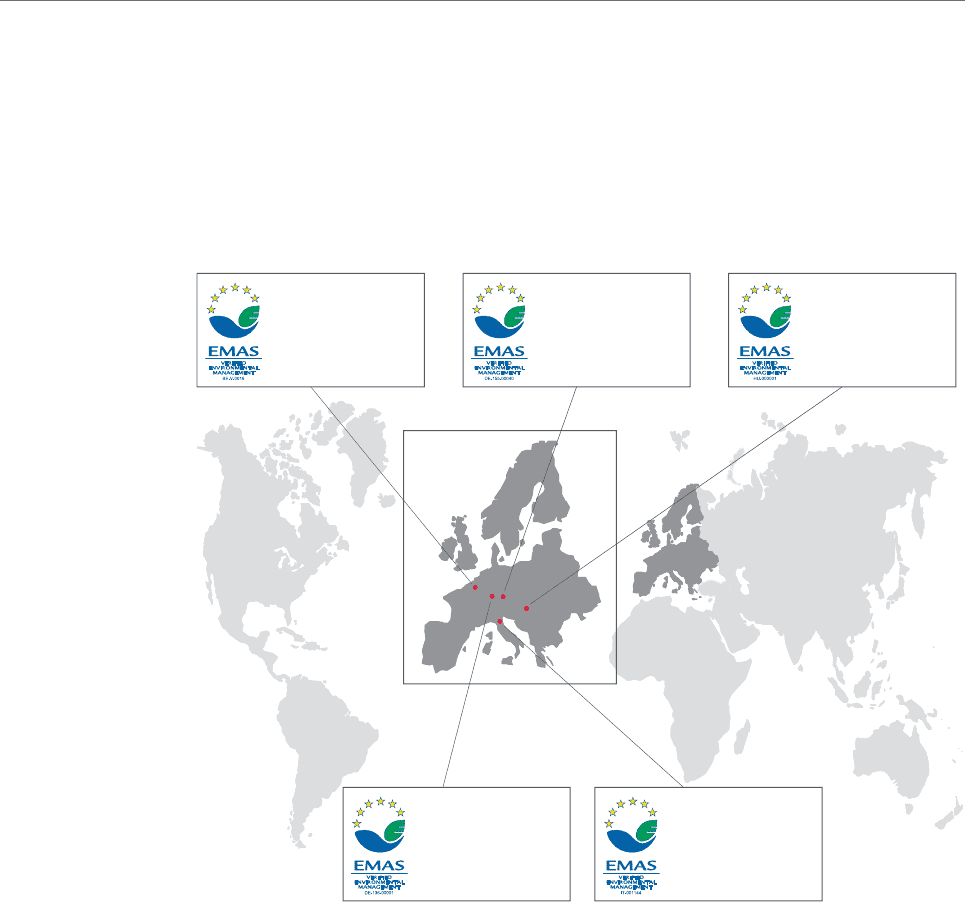

location. The two production plants Ingolstadt and Győr (Hungary) followed in 1997 and 1999.

The Belgian plant in Brussels has held the EMAS certificate since 2002, being joined in 2009 by

the Lamborghini location Sant’Agata Bolognese (Italy). The Ingolstadt, Győr and Sant’Agata

Bolognese manufacturing plants are moreover accredited under the worldwide DIN EN ISO

14001 standard. In addition, the environmental management systems of the Ingolstadt and

Neckarsulm plants already satisfy the new European standard DIN EN 16001, which sets partic-

ularly ambitious targets for the gradual, systematic reduction of energy consumption.

ACCREDITATION OF AUDI GROUP LOCATIONS

Győr/Hungary

AUDI HUNGARIA

MOTOR Kft.

DIN EN ISO 14001

Ingolstadt/Germany

AUDI AG

DIN EN ISO 14001

DIN EN 16001

Brussels/Belgium

AUDI BRUSSELS

S.A./N.V.

Neckarsulm/

Germany

AUDI AG,

quattro GmbH

DIN EN 16001

Sant’Agata

Bolognese/Italy

Automobili

Lamborghini S.p.A.

DIN EN ISO 14001

The environmental declarations for the individual locations are each available in the local language on the respective

companies’ websites.

Emissions reduction and resource efficiency

Environmental activities place particular focus on reducing energy consumption and related

emissions; the potential for saving energy is already taken into account in the planning phase.

AUDI AG has set itself the overall goal of reducing location-based and company-specific CO₂

emissions by 30 percent by 2020, against the base year of 1990, through a wide range of

ongoing measures.

As well as infrastructure and logistics, the production and supply facilities are key areas offering

scope for permanent efficiency gains. For example, when the engine test benches at Neckarsulm

are running, they can generate power for use at the plant by being connected up to generators.

The use of an extra-light body manufacturing tool made largely from carbon fiber and developed

by the Audi Toolmaking Shop cuts power consumption by around 43 percent compared with a