Volvo 2002 Annual Report Download - page 27

Download and view the complete annual report

Please find page 27 of the 2002 Volvo annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

engine development and each applica-

tion, to ensure the right combination of

engine, transmission, chassis and body.

The new I-shift transmission used in the

Volvo Trucks is an excellent example of

this integration.

The striving for higher fuel efficiency

and lighter components requires that new

material technologies are being de-

veloped also for engines. The so-called

FPC method developed for use in the

Skövde foundry produces a material with

higher strength and thus withstanding

higher combustion pressure. The method

was acknowledged by the international

foundry organization WFO by its first

environmental prize in June 2002. Among

the side-effects are also higher energy

efficiency and less handling of hazardous

waste in the foundry process.

Climate change

The focus on fuel efficiency is the Group’s

strongest contribution to reducing green-

house gas emissions. The specific fuel

consumption for each product must be

minimized. Total efficiency will also be

improved through the development and

use of information technology and intelligent

planning systems.

A road-map for alternative fuels and

powertrains for the products is being

developed, taking advantage of the deep

knowledge on how to keep the efficiency

of the diesel engine technology also with

other fuels. DME is further investigated

with test vehicles, and most importantly

also the fuel production and distribution

prerequisites for an overall efficient solution.

The focused environmental agenda

defines far-reaching objectives for energy

efficiency also in the production process-

es. The organisation is now being chal-

lenged on how to achieve substantially

decreased CO2emissions in the most

cost-effective way.

The production impact

The Volvo Group has production sites on

all continents. Minimum environmental

performance and an on-going improve-

ment program are required from all plants,

and followed-up by regular audits since

1989. The environmental audits identify

environmental risks and possible need for

clean-up or other corrective actions, with

a follow-up that these are promptly con-

ducted. The Volvo Group has insurance

coverage for possible accidental damage

to nearby areas.

At the beginning of 2003, Volvo had a

total of 48 plants for the production of

trucks, buses, construction equipment, mar-

ine and industrial power systems, and air-

craft engines, of which 16 in Sweden. All

the plants have the requisite permits, which

in Sweden cover waste, noise and emis-

sions to air, water and soil. No Swedish

permits are to be renewed during 2003.

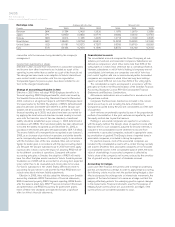

The 2002 consumption of water and

energy, and thus the emissions of CO2

and NOxhave remained on roughly the

same levels as 2001. The newly acquired

plants have started an intense work to

increase resource efficiency, but the

results cannot be seen yet. However their

focus on changing to fuel with lower sulfur

content shows clear results by decreased

sulfur dioxide emissions. Solvent emis-

sions and hazardous waste show minor

increases. Detailed data can be found on

page 89.

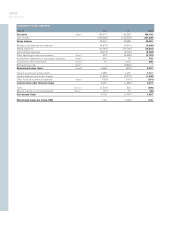

98 99 00 01 02

1. 8 1. 8 1.72.62.6

Energy consumption

Energy, TWh

Energy/net sales

MWh/SEK M

16 .5 15.6 13.8 14.3 14.5

98 99 00 01 02

5.3 6.7 6.1 9.2 9.2

Water consumption

Water, Mm3

Water/net sales

m3/SEK M

49.1 57.8 51.0 50.9 52.0

98 99 00 01 02

10.8 15.6 17.2 20.3 20.5

Hazardous waste

k ton

kg/SEK M

101 13 4 143 112 116

98 99 00 01 02

1.1 1.3 1.4 1.8 1.9

Solvent emission

Emissions, k ton

Emission/net sales

kg/SEK M

10.0 11.4 11.8 10.1 10.7