Audi 2011 Annual Report Download - page 98

Download and view the complete annual report

Please find page 98 of the 2011 Audi annual report below. You can navigate through the pages in the report by either clicking on the pages listed below, or by using the keyword search tool below to find specific information within the annual report.

Sustained success is not only

defi ned by positive growth

in the key fi nancial fi gures –

it is also defi ned above all by

environmental responsibility.

We’ve been setting an example

in this area for a long time –

not because we have to, but

because we feel an obligation

to do so. We do not wait for

external pressure – the best

ideas at Audi come from inter-

nal sources. This is the pioneer-

ing spirit that has made our

company what it is today –

and it is what continues to

drive us. It is also behind our

commitment to the environ-

ment. One of my goals is to

neutralize CO₂ emissions

at our corporate sites. We

are achieving this by forging

new paths, researching new

technologies and continuously

thinking outside the box.

We need energy to produce

cars. But we can ensure that

we acquire this energy in

an environmentally compatible

way. We have already realized

numerous projects at the

Ingolstadt site alone. Effi cient

solutions such as using waste

heat, heat recovery systems

and trigeneration plants have

proved eff ective for many

years now. We are continuing

down this path with deter-

mination – with ideas that,

like Audi itself, might be

considered a bit “diff erent.”

“We have

to continuously

think outside

the box.”

Frank Dreves

Production

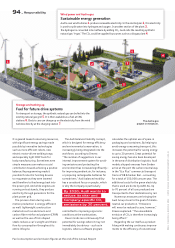

drive systems, Audi is also currently

fi eld-testing innovative drive systems

and fuels under realistic conditions in

three test series. These could help lower

emissions during driving. The prototype

Audi Q5 HFC draws its energy from a

fuel cell and tanks up on hydrogen. The

batteries for Audi A1 e-tron cars with an

electric drive system, which are currently

being driven in fl eet trials in Munich,

can be conveniently charged from the

electricity grid. And the Audi A3 TCNG,

which will begin rolling off the assembly

lines in late 2013, can fi ll up at any

natural gas fueling station.

Still, the Audi Group believes that it is

not enough merely to develop innovative

automotive drive systems to the point

where they are ready to use and then

introduce them to the market. As a

carmaker that thinks systematically,

Audi also has to keep an eye on having

an appropriate energy supply. This is why

Audi balanced mobility also includes

the e-gas project, in which excess wind

power is used to produce hydrogen and

synthetic methane. This should make

carbon-neutral mobility possible.

“At this moment we are realizing a

system that should make climate-neutral

driving possible for owners of Audi

models that run on electricity, hydrogen

or natural gas,” explained project man-

ager Reiner Mangold. The goal: cars that

drive with wind or solar power. Eff orts

to implement this concept are based on

familiar technologies. With the aid of

electricity, water is split into oxygen and

hydrogen in an electrolyzer. And by

adding carbon dioxide, hydrogen can be

converted into methane, which has the

same properties as natural gas. Thus,

it can be liquefi ed, transported through

pipelines, stored in caverns or tanks,

converted into electricity or used for

heating. It can also be used as a fuel

for cars. “So thanks to this technology,

there are three energy sources of the

future available simultaneously,”

Mangold emphasized: electricity, hydro-

gen and synthetic natural gas – known

at Audi as e-gas. Plus, there is another

special advantage: if you begin the

methanization process with electricity

produced from renewable resources and

add, for instance, CO₂ from a biogas

plant – which would otherwise reach

the atmosphere directly as emissions –

the synthetic methane produced in this

way is climate-neutral when used as a

fuel for cars.

Together with the company SolarFuel

GmbH, AUDI AG decided in May 2011

to establish the world’s fi rst industrial-

scale experimental plant. The plant,

being developed in the town of Werlte

in Lower Saxony, is planned to pro-

duce about 1,000 tons of e-gas annually

in the next few years – which will

enable 1,500 A3 TCNG cars to travel

15,000 kilometers each per year.

Another 150 tons of e-gas can also be

used in the public power grid for other

purposes, such as for the production

of electricity during low-wind periods.

The plant in Werlte is one link in a

comprehensive chain of energy pro-

duction: It will acquire the renewable

electricity from Audi wind turbines in

the North Sea off shore wind farm.

Electricity for operating the Audi e-tron

can then be obtained directly from the

power grid. The hydrogen that is pro-

duced through electrolysis is converted

into e-gas and fed into the existing

natural gas grid. Mangold sees an

“enormous inherent advantage” here

over hydrogen: “The natural gas distri-

bution network already exists. This

makes energy-consuming transport and

intensive investment unnecessary.”

Mangold highlights yet another major

strength of the e-gas project: “There’s

no need to place our hopes on tomorrow;

the infrastructure already exists.”

As soon as the plant in Werlte begins

operation, owners of an A3 TCNG will be

off ered the option to acquire e-gas.

The volume of natural gas they use to

tank up their cars will be compensated

for by feeding the corresponding

amount of e-gas into the grid. Its use as

a fuel will then be allocated through a

balancing group method. This will make

climate-neutral driving a reality.

The major strength

of the e-gas project:

the infrastructure

already exists.

Expedition on a 1:87 scale:

learn more about the Audi

e-gas project in miniature.